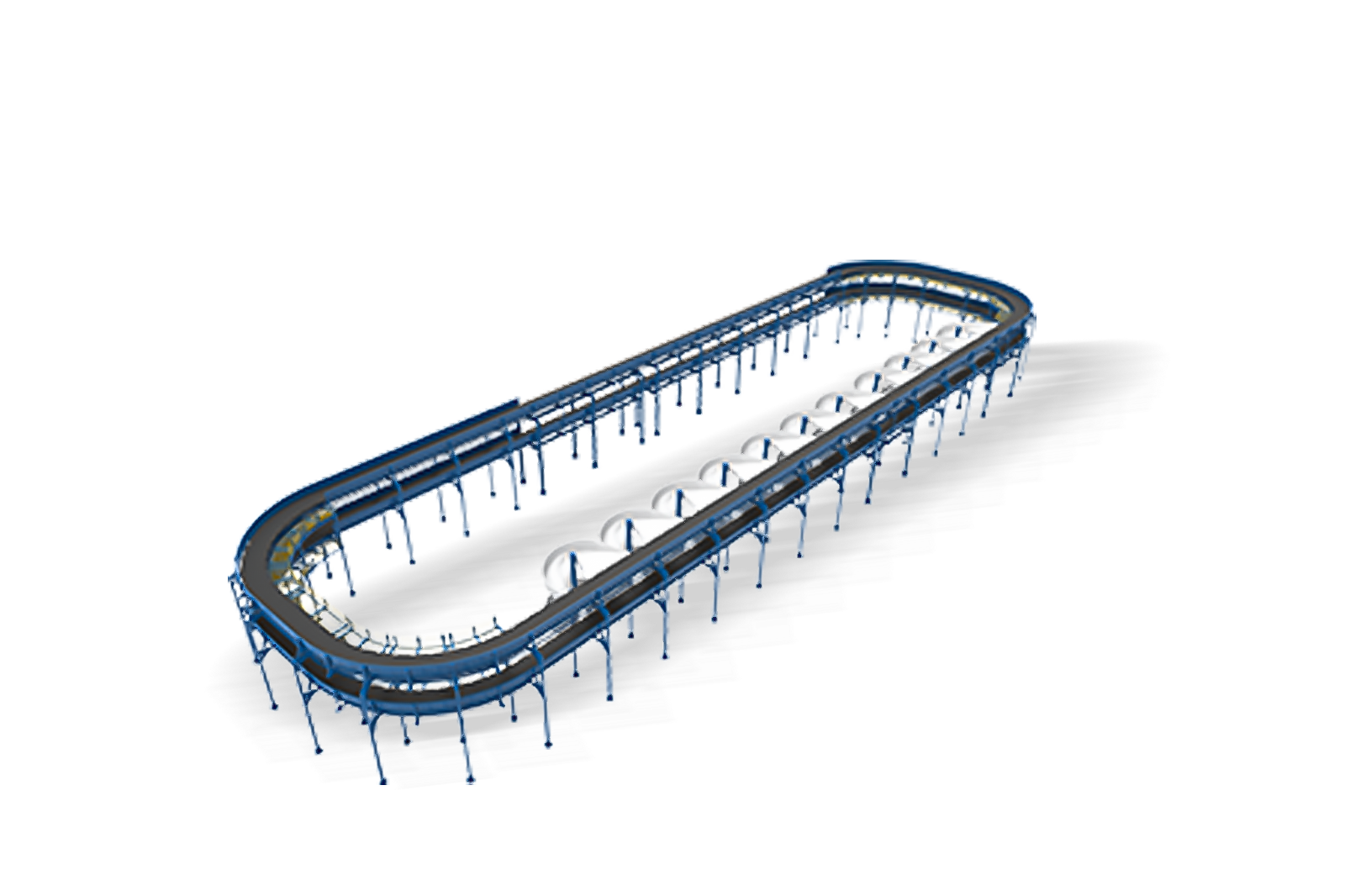

With e-commerce demand showing no signs of slowing, warehouses across Australia are under immense pressure to process orders faster and more accurately than ever before. SmartlogitecX Automated sorting systems have emerged as the cornerstone of modern warehouse automation strategies, transforming how logistics and fulfilment centres manage the relentless flow of packages from receipt to dispatch. These sophisticated systems represent far more than simple mechanical upgrades—they fundamentally reimagine how warehouses operate, combining advanced technologies with intelligent software to create seamless, highly efficient operations. As businesses grapple with rising order volumes and customer expectations for rapid delivery, understanding the transformative benefits of automated sorting becomes essential for maintaining competitive advantage in today’s demanding market.

Boost Operational Efficiency and Throughput

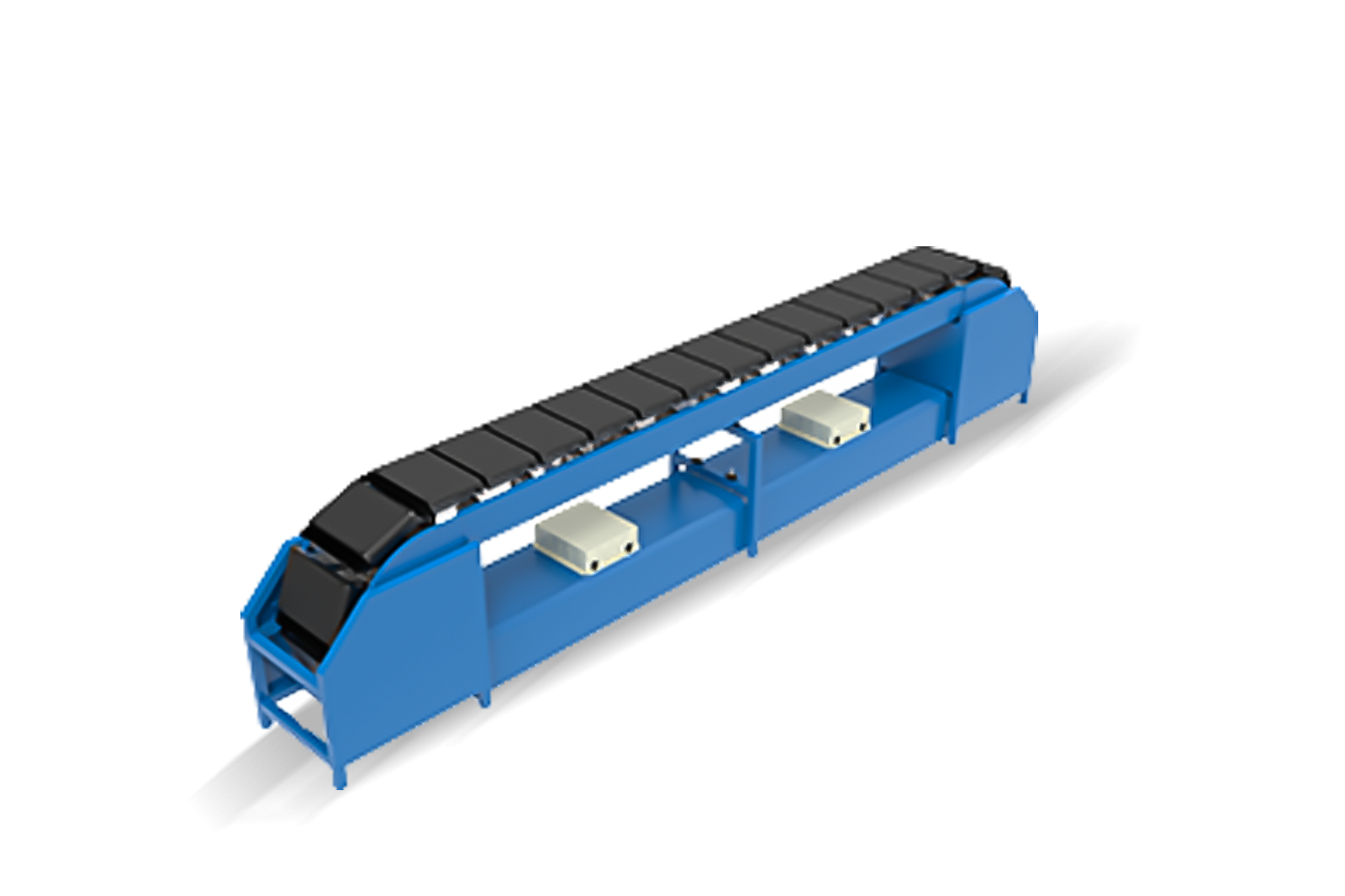

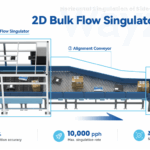

The stark contrast between automated and manual sorting reveals why businesses are rapidly embracing this technology. Where human workers might process 60-100 items per hour with inevitable fatigue setting in, automated systems maintain consistent speeds of 3,000-10,000 items hourly, operating continuously without breaks or shift changes. Modern warehouse conveyor systems form the backbone of this enhanced productivity, working in concert with robotic arms and intelligent routing software to create a symphony of coordinated movement. Cross-Belt Sorters and Pivot Wheel Sorters exemplify this efficiency, dynamically adjusting to package dimensions and destinations whilst maintaining optimal throughput rates. During peak seasons when order volumes surge by 300-400%, these systems prove invaluable, handling the increased demand without the traditional scramble for temporary labour or the quality compromises that often accompany rushed manual sorting processes.

Realise Significant Cost Savings and ROI

The financial mathematics of automated sorting systems paint a compelling picture for warehouse operators seeking sustainable operational models. Labour costs, typically representing 50-65% of warehouse operational expenses, dramatically decrease as automation reduces dependency on manual sorting teams whilst simultaneously minimising costly errors that lead to returns and reshipments. This predictable cost structure transforms volatile labour markets and seasonal fluctuations from major concerns into manageable considerations, with many operations reporting ROI achievement within 18-24 months of implementation.

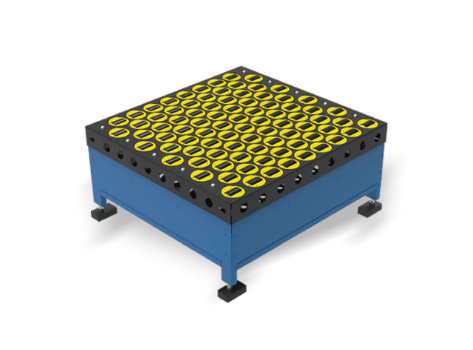

Optimise Your Warehouse Footprint with Automated Storage

The integration of automated storage and retrieval systems (ASRS) with sorting technology creates remarkable space efficiencies that would seem impossible with traditional warehouse layouts. These high-density storage solutions utilise vertical space that manual operations cannot safely access, often doubling or tripling storage capacity within the same footprint. The automated storage retrieval system coordinates seamlessly with sorting mechanisms, creating a fluid movement of goods from storage to dispatch without the wide aisles and clearances required for human navigation. This spatial optimisation translates directly into reduced property costs and eliminates the need for expensive warehouse expansions, making automated storage a cornerstone of any comprehensive warehouse automation solution.

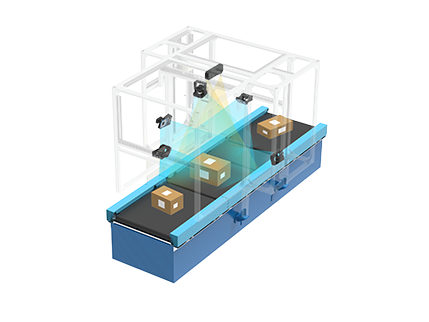

Achieve Unmatched Accuracy and Reduce Errors

Human error in manual sorting typically ranges from 1-3%, a seemingly small percentage that represents thousands of misrouted packages in high-volume operations. Automated sorting systems routinely achieve accuracy rates exceeding 99.9%, utilising multiple verification technologies including barcode scanners, RFID readers, and sophisticated computer vision systems that capture package characteristics in real-time. Dynamic Dimensioning, Weighing, and Scanning (DWS) systems add another layer of precision, automatically capturing critical package data that ensures proper routing and billing accuracy. This near-perfect accuracy ripples through the entire supply chain, reducing customer complaints by up to 80%, slashing return processing costs, and building the kind of reliability that strengthens brand reputation in competitive markets.

Enhance Workplace Safety and Optimise Labour

The human impact of automation extends far beyond simple job displacement narratives, creating fundamentally safer working environments whilst elevating employees to more strategic roles. Repetitive strain injuries, back problems from heavy lifting, and accidents from manual handling decrease by up to 70% when automated systems assume these physically demanding tasks. Rather than eliminating jobs wholesale, successful implementations redistribute human talent toward quality control, system maintenance, customer service, and complex problem-solving roles that machines cannot replicate. This labour optimisation creates more engaging work experiences, reduces costly worker compensation claims, and addresses the chronic labour shortages plaguing the logistics industry by making remaining positions more attractive and sustainable for long-term employment.

Unlock Scalability and Future Proof Your Operations

The modular architecture of modern warehouse automation systems provides unprecedented flexibility for growing businesses. Unlike rigid manual processes that require proportional increases in labour and space as volume grows, automated sorting systems scale elegantly through software updates, module additions, or throughput optimisations. Integration with sophisticated Warehouse Management Systems (WMS) provides real-time data analytics that inform strategic decisions about capacity planning, seasonal adjustments, and operational refinements. Emerging technologies like artificial intelligence and machine learning continuously enhance these systems’ capabilities, enabling predictive maintenance, adaptive routing algorithms, and self-optimising workflows that improve performance over time rather than degrading like manual processes.

Making the Smart Move to Warehouse Automation

The convergence of efficiency gains, cost reductions, accuracy improvements, safety enhancements, and scalability positions warehouse automation as an essential strategic investment rather than an optional upgrade. Businesses implementing these warehouse automation products consistently report transformative results: processing times cut by 60%, labour costs reduced by 40%, and customer satisfaction scores reaching unprecedented heights. The transition to automated sorting represents more than technological advancement—it signifies a commitment to operational excellence and long-term competitiveness in an increasingly demanding marketplace. As supply chains become more complex and customer expectations continue rising, warehouse automation services will transition from competitive advantage to baseline requirement for businesses serious about their logistics capabilities.

Frequently Asked Questions

1.What is the main purpose of an automated sorting system?

Automated sorting systems primarily aim to accelerate package processing whilst maintaining exceptional accuracy levels. They replace manual sorting processes with technology-driven solutions that can handle thousands of items per hour, routing packages to correct destinations based on programmed parameters like size, weight, destination, or priority level.

2.How do automated sorting solutions reduce labour costs?

Labour cost reduction occurs through decreased staffing requirements for sorting operations, reduced overtime during peak periods, and lower training expenses. Additionally, fewer workplace injuries mean reduced compensation claims and insurance costs, whilst improved accuracy minimises the labour required for error correction and returns processing.

3.What is the typical return on investment for warehouse automation?

Most warehouse automation implementations achieve ROI within 18-24 months, though this varies based on operation scale and complexity. Factors influencing ROI include volume throughput, current labour costs, error reduction rates, and space utilisation improvements, with some high-volume operations seeing payback periods as short as 12 months.

4.Can automated sorting systems handle different types of products?

Modern automated sorting systems demonstrate remarkable versatility, handling everything from small parcels to oversized packages, fragile items to heavy goods. Advanced sensors and adjustable mechanisms adapt to varying product dimensions, weights, and handling requirements, making them suitable for diverse inventory profiles.

5.How does an automated storage and retrieval system (ASRS) work?

An ASRS uses computer-controlled systems to automatically place and retrieve items from defined storage locations. Guided by warehouse management software, robotic cranes or shuttles navigate storage racks, retrieving requested items and delivering them to sorting stations or picking areas without human intervention.

6.Are automated sorters more accurate than manual sorting?

Automated sorters consistently achieve accuracy rates exceeding 99.9%, compared to manual sorting accuracy of 97-99%. This improvement stems from elimination of human fatigue, consistent application of sorting rules, and multiple verification technologies that catch potential errors before packages leave the facility.

7.How does warehouse robotics fit into an automated sorting process?

Warehouse robotics complement sorting systems through various applications including robotic arms for package manipulation, autonomous mobile robots for transport between stations, and collaborative robots that work alongside humans for complex sorting tasks requiring flexibility and decision-making capabilities.

8.What are the safety benefits of automated sorting?

Safety improvements include dramatic reductions in repetitive strain injuries, elimination of heavy lifting requirements, decreased forklift traffic in sorting areas, and removal of workers from potentially hazardous conveyor zones. These changes typically reduce workplace accidents by 60-70%.

9.How do these systems improve warehouse space utilisation?

Automated systems require narrower aisles, utilise vertical space more effectively, and eliminate staging areas required for manual sorting. This optimisation often increases storage capacity by 40-60% within existing facilities, postponing or eliminating needs for facility expansion.

10.Can automated sorting systems scale as a business grows?

The modular design of contemporary sorting systems enables seamless scaling through additional sorting modules, software capacity upgrades, or integration of new technologies. This scalability allows businesses to expand sorting capacity by 20-200% without replacing entire systems, protecting initial investments whilst accommodating growth.