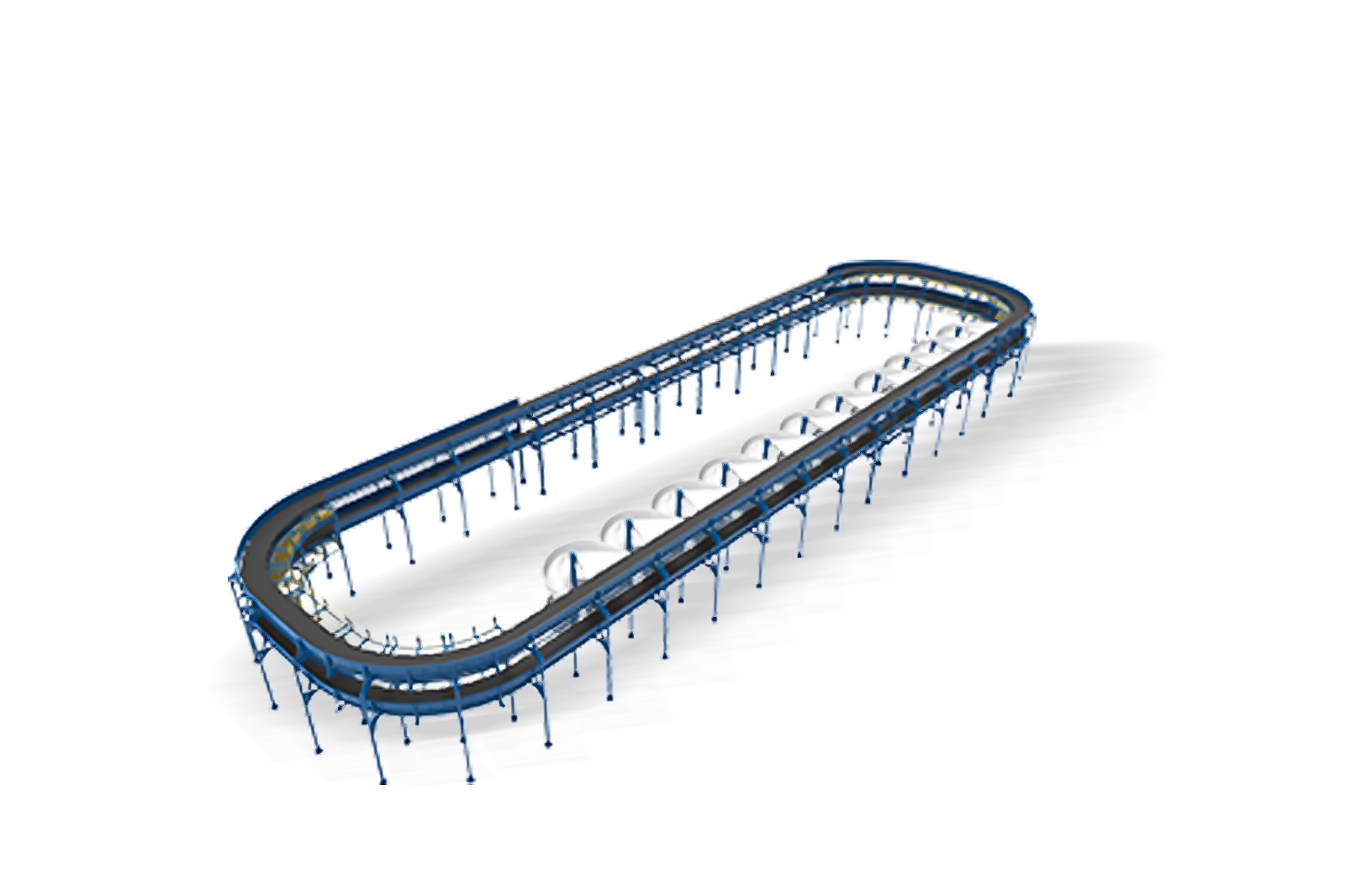

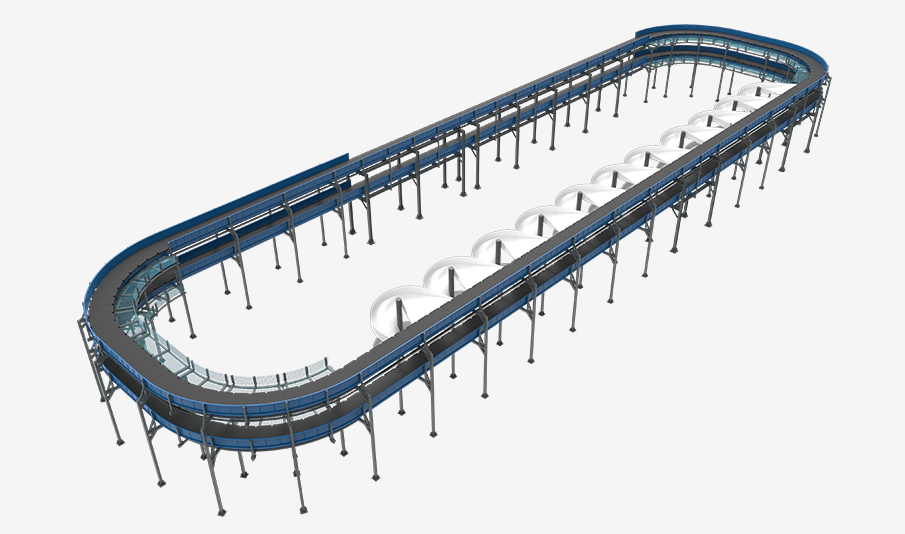

Cross Belt Sorting System

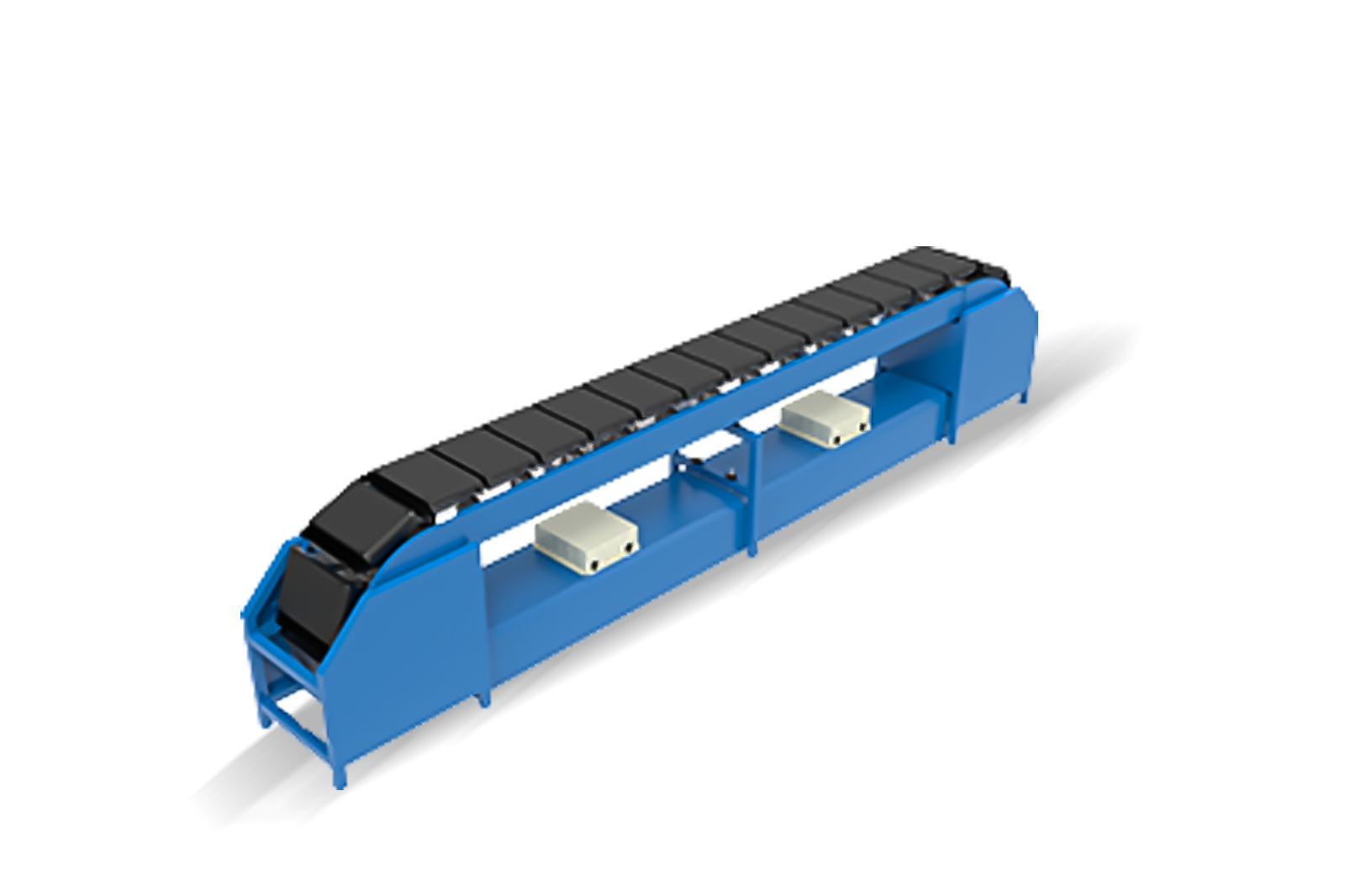

3D Bulk Flow Singulator

2D Bulk Flow Singulator

The equipment obtains parcel barcode information and uploads the information to the management system, and then the parcels are conveyed to the pivot wheel sorter after barcode scanning.

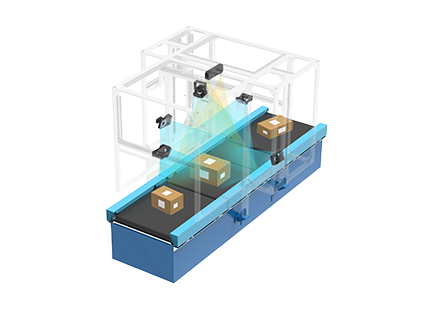

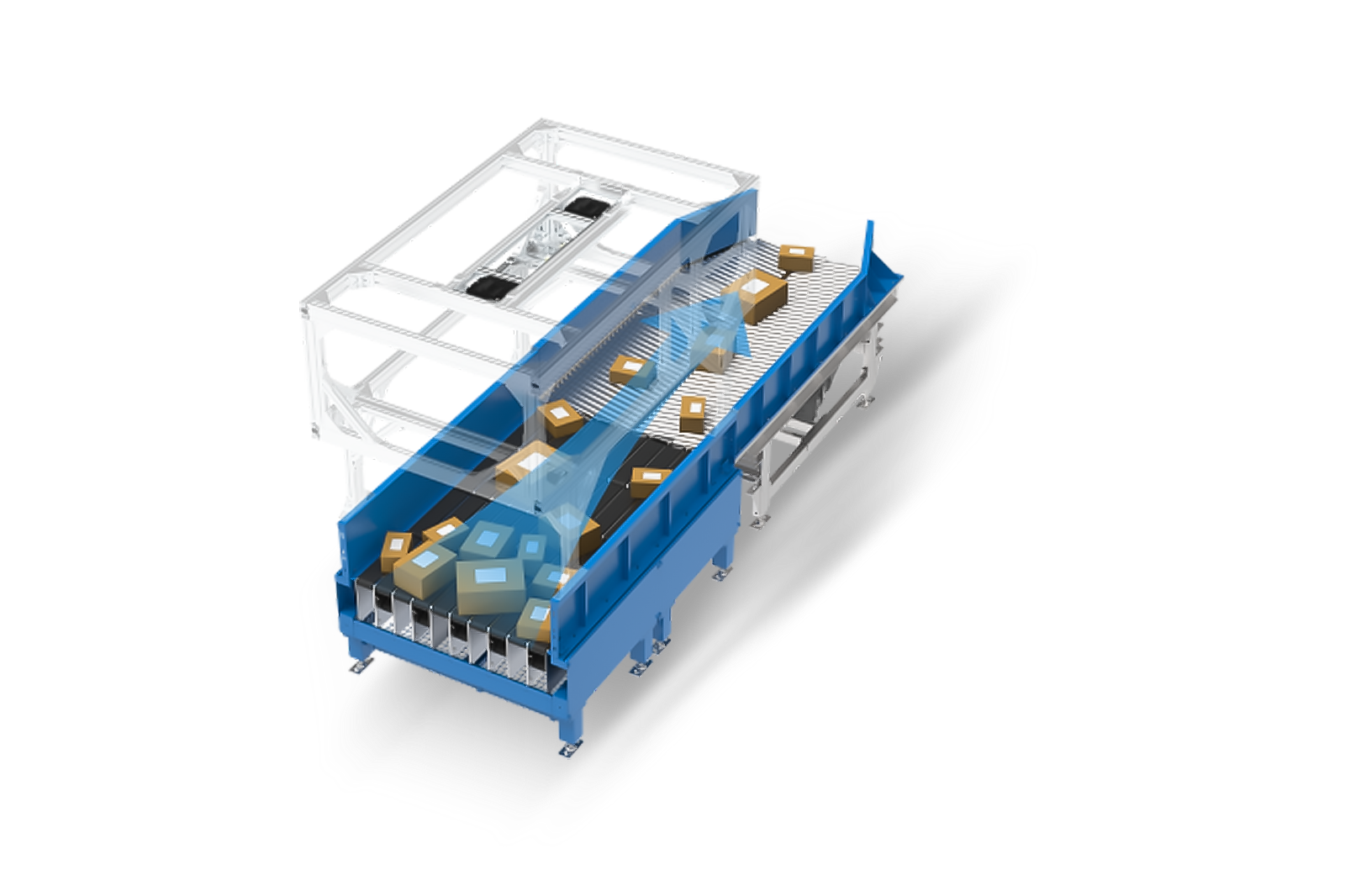

Automated Infeed System

By an intelligent camera with a high-speed six-axis robot, the automated robotic parcel infeed system of Wayzim efficiently and accurately identifies parcels.

Calculates their spatial location information based on instance segmentation based on a deep learning network and three-dimensional spatial point cloud algorithm for full-time and efficient pickup of the parcels.

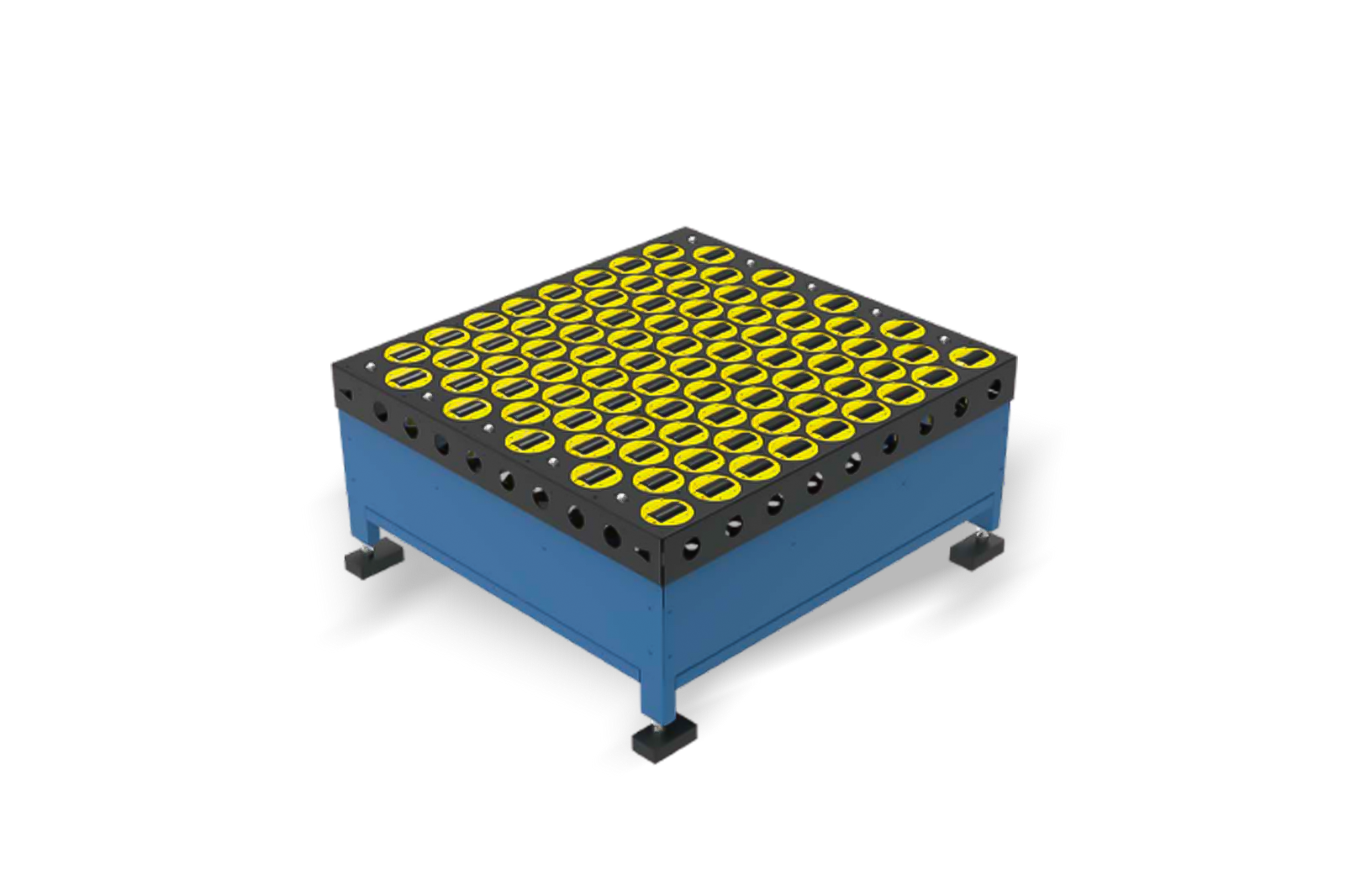

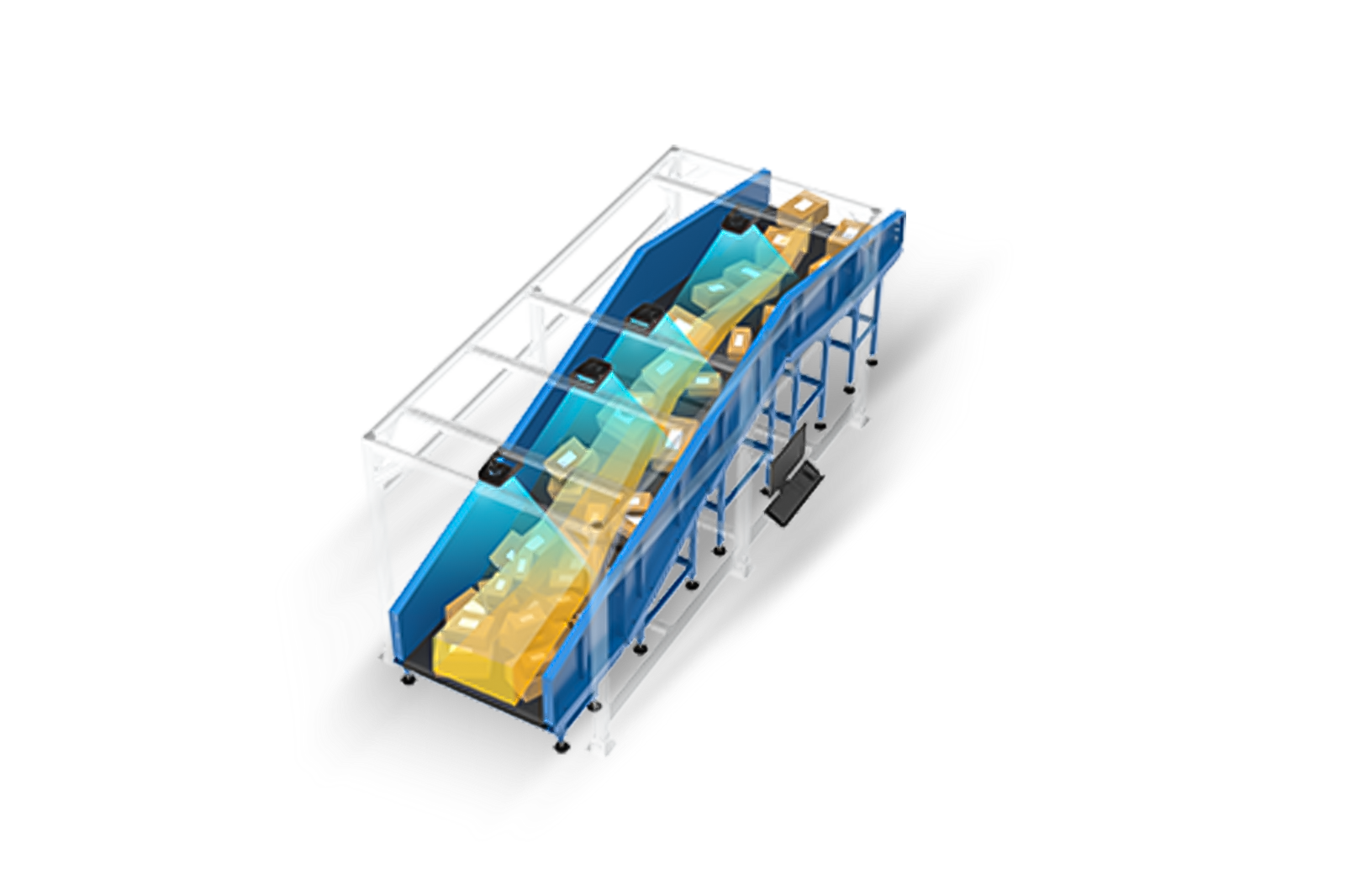

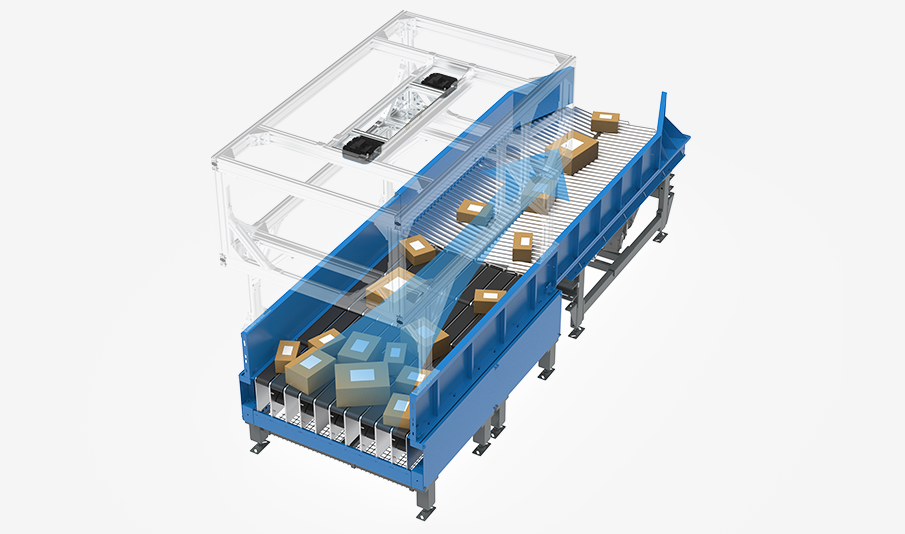

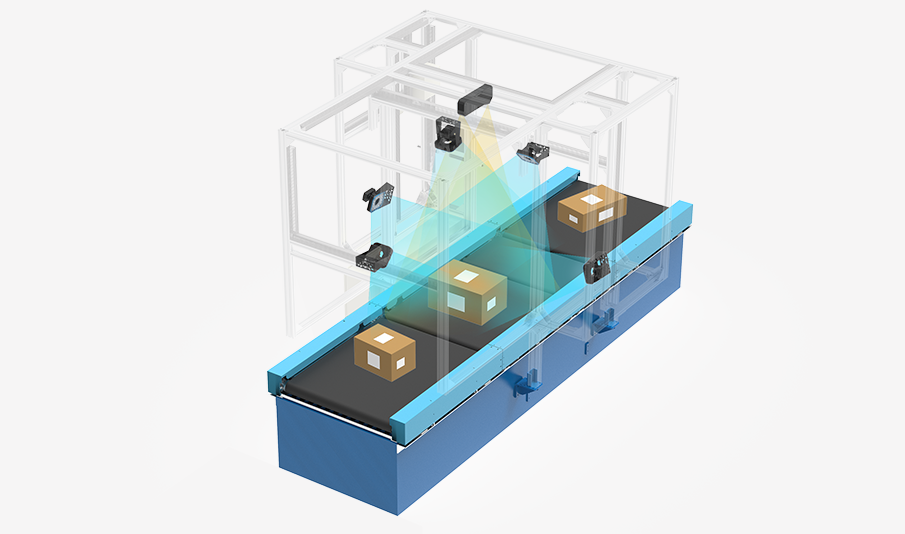

DWS System

With Wayzim’s high-resolution intelligent barcode reading cameras, volumetric meters, and dynamic weighing modules, the system can efficiently achieve real-time accurate collection and output of major information: barcode, volume and weight.

The system works with sorting equipment for automated sorting of express parcels.

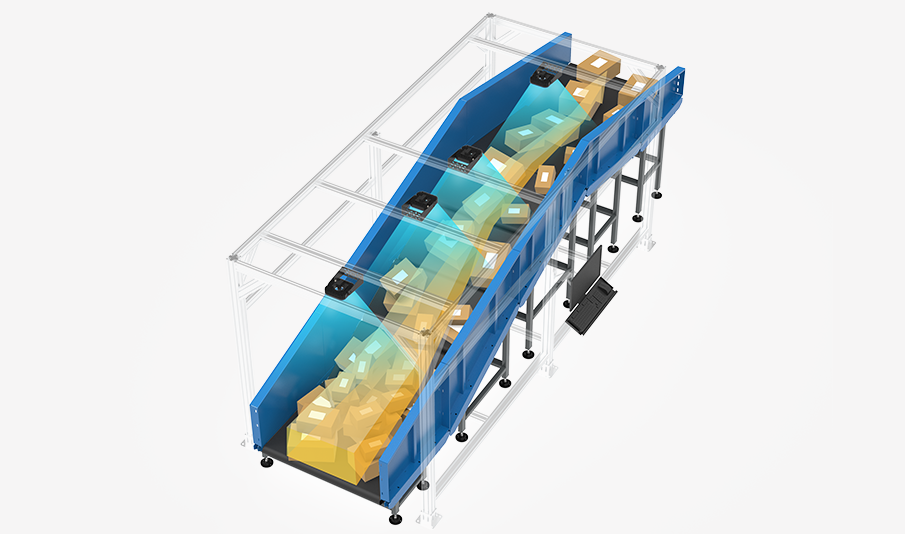

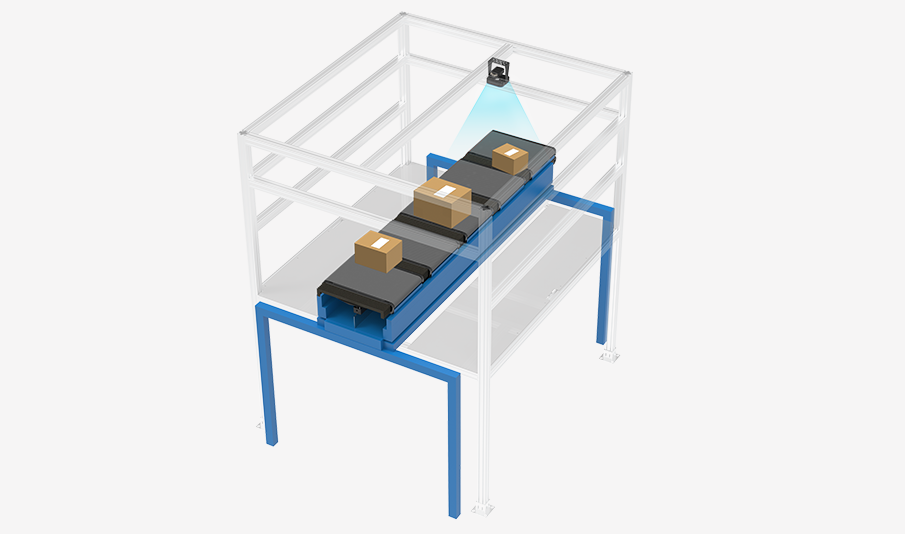

Position Detection System

It integrates parcel center position detection, edge detection, detection of one carrier with multi-parcel, offset correction detection, and empty pallet detection, outputs express parcel dimensions and position information, and corrects offset express parcels.