Packaging Process

In the packaging process, through technologies such as automatic identification, automatic package cutting, automatic waybill pasting, and automatic rechecking, the operation efficiency is greatly improved by standardized operation and technical intelligence.

Main products: robot palletizing, labor assisted carton changing, and automatic carton induction into containers

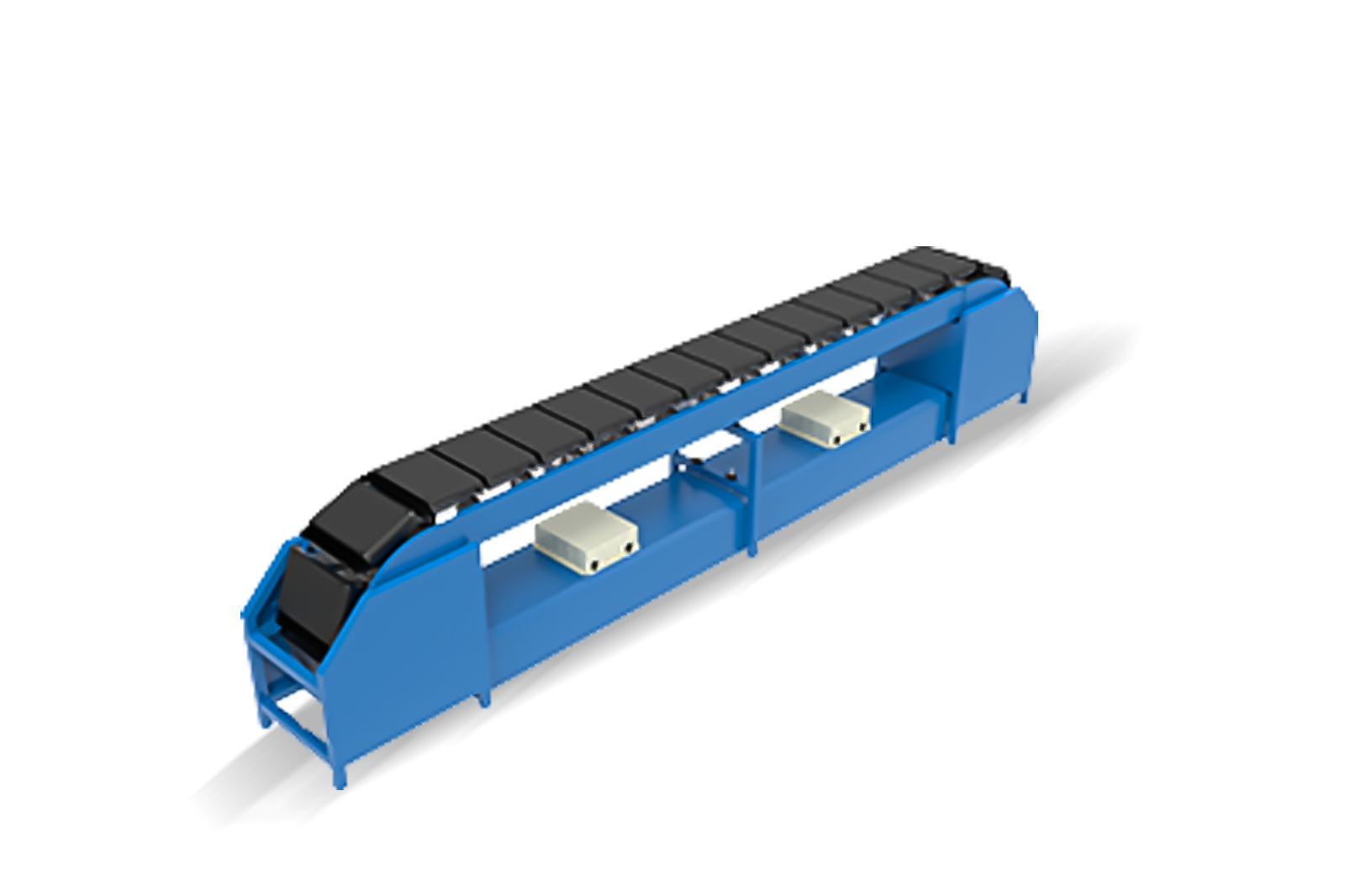

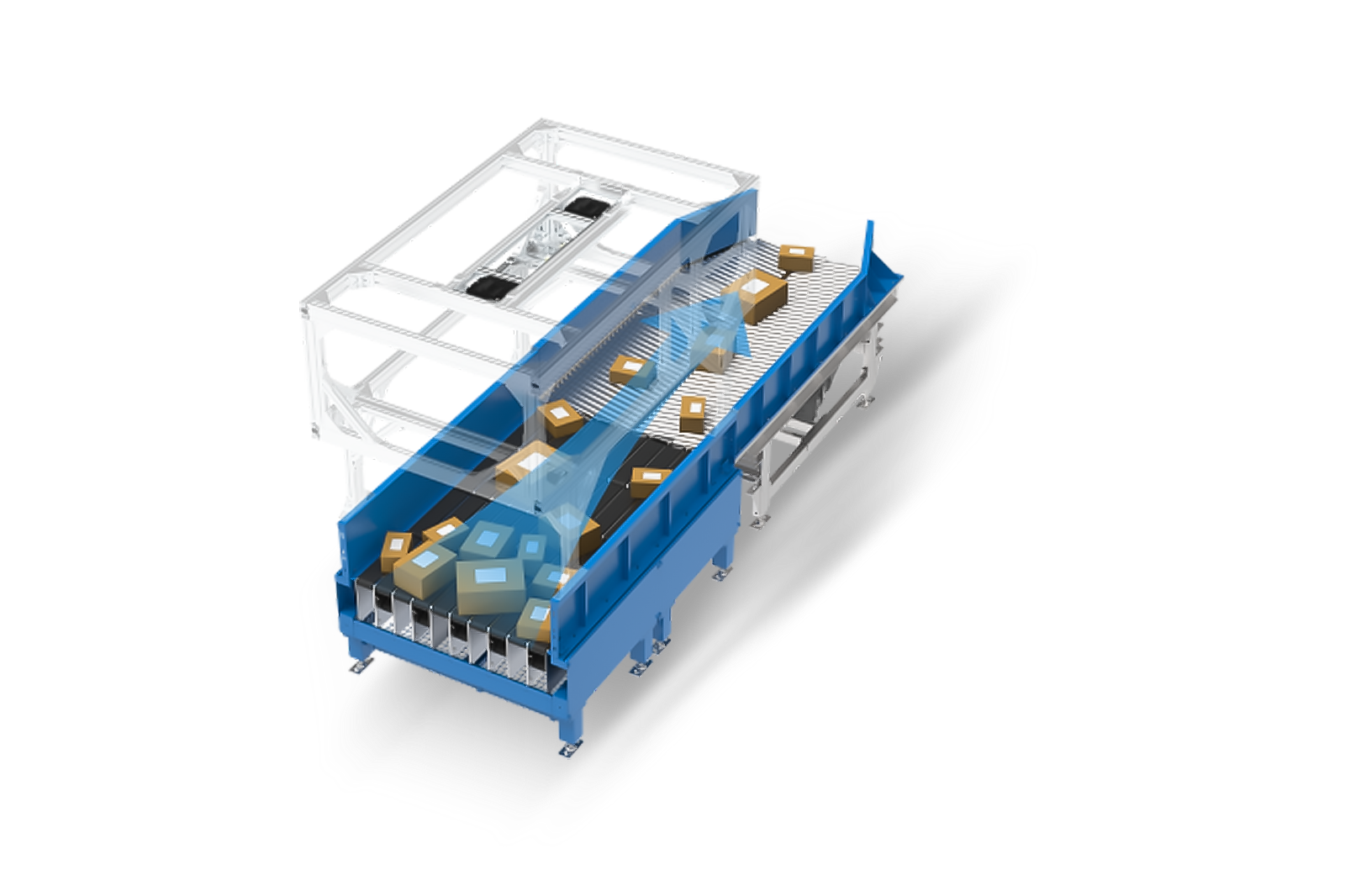

Inbound Process

In the acceptance and inbound processes, intelligent equipment is used to check and accept the quantity and appearance of goods based on the delivery note, and quickly read the information of goods and collect relevant data information of drugs, thus improving the efficiency and accuracy of acceptance and inbound.

Main products: Tote Conveyor Line, AGV, Rail Carrier, and Pallet Conveyor Line

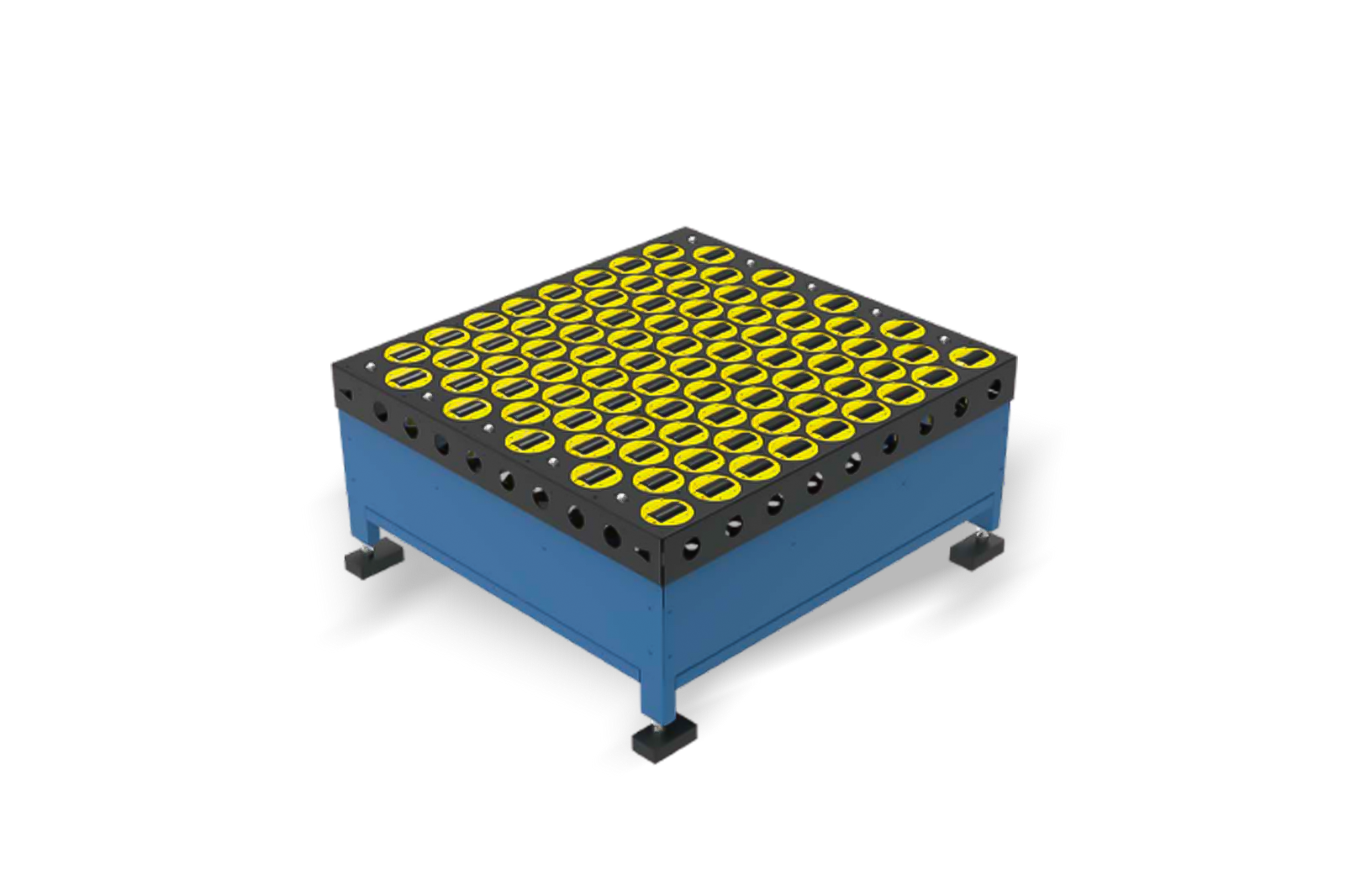

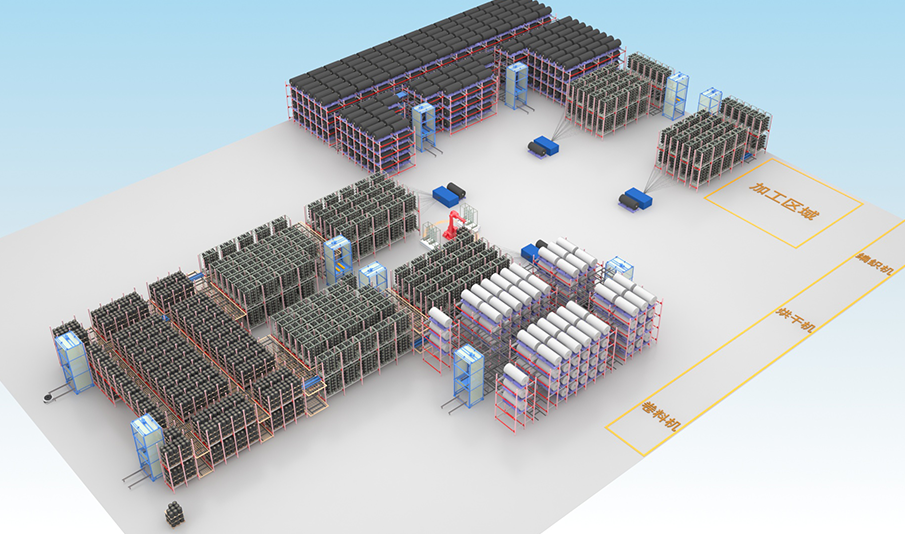

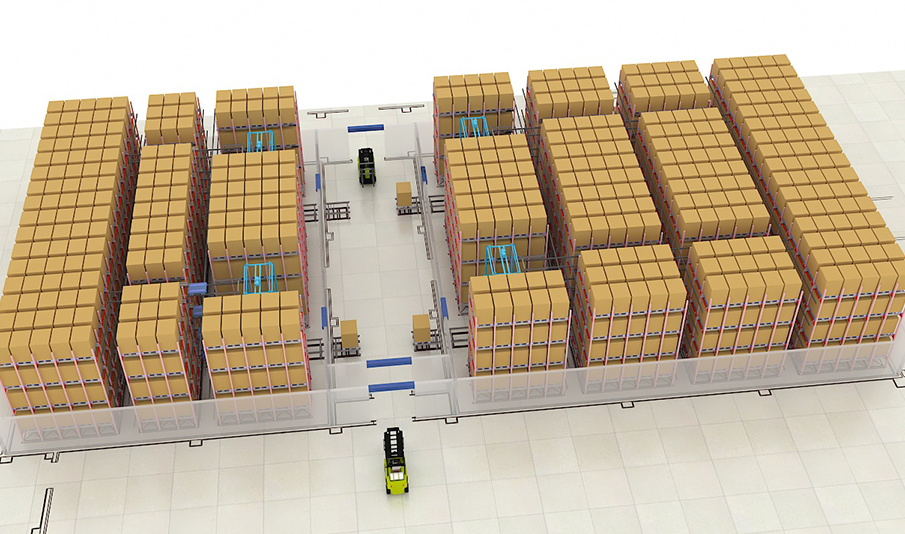

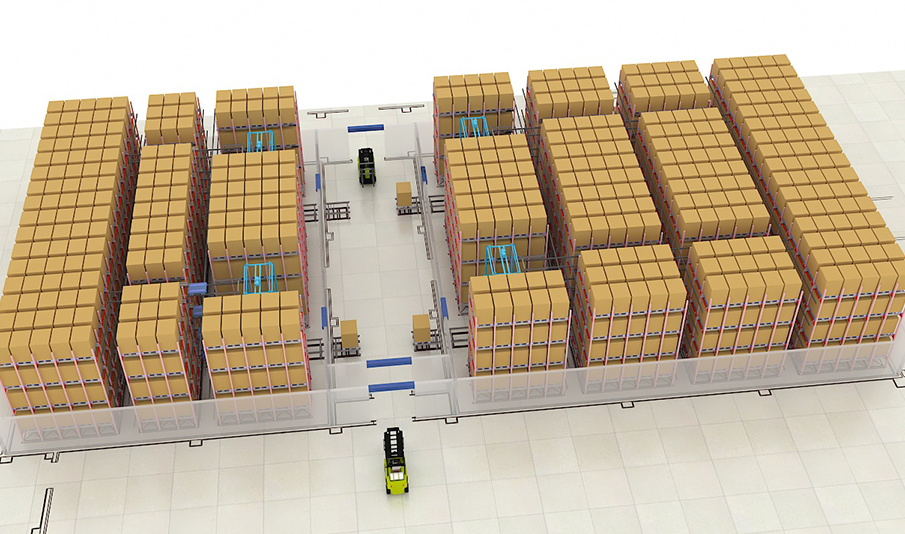

Storage Process

In the storage process, the system implements inbound and putaway & distribution operations based on the categories and quantity of goods, arranges goods and prints and pastes labels, and implements inbound and putaway operations in accordance with label tips. After dimensional detection, weight measurement, and barcode scanning, goods pallets are conveyed to designated locations such as high-bay warehouses, automated multi-level warehouse, and one-story warehouses with intelligent equipment.

Main products: Automated Warehouse by Tote Stacker Crane, Tote Multi-Shuttle System, Autostore, and Automated Warehouse by Pallet Stacker Crane

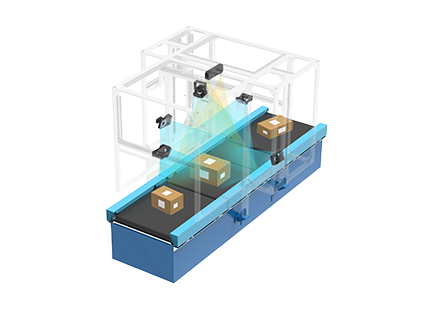

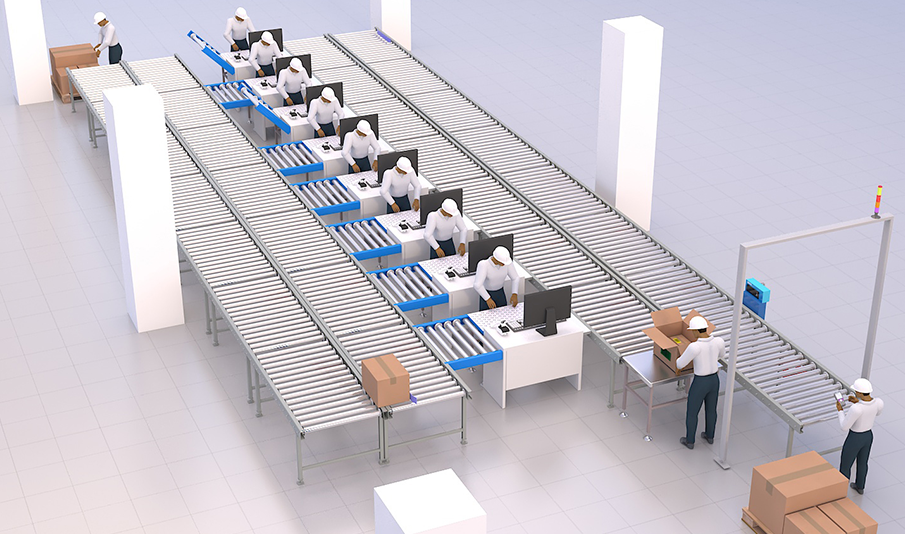

Picking Process

In the picking process, goods are handled from the high-bay warehouse to the designated locations such as the one-story warehouse through pallets and can achieve automatic putaway & takeout and inventory transfer operations by flexibly using intelligent handling equipment such as stacker cranes and shuttles. Customized sorting solutions can be provided for different business processes, goods, order quantities and warehouse capacities to improve productivity, throughput, conveying accuracy and other indicators.

Main products: robot-assisted order picking upon goods arrival, robot-assisted picking & packing upon goods arrival, manual picking upon goods arrival, light-guided and voice-guided picking.

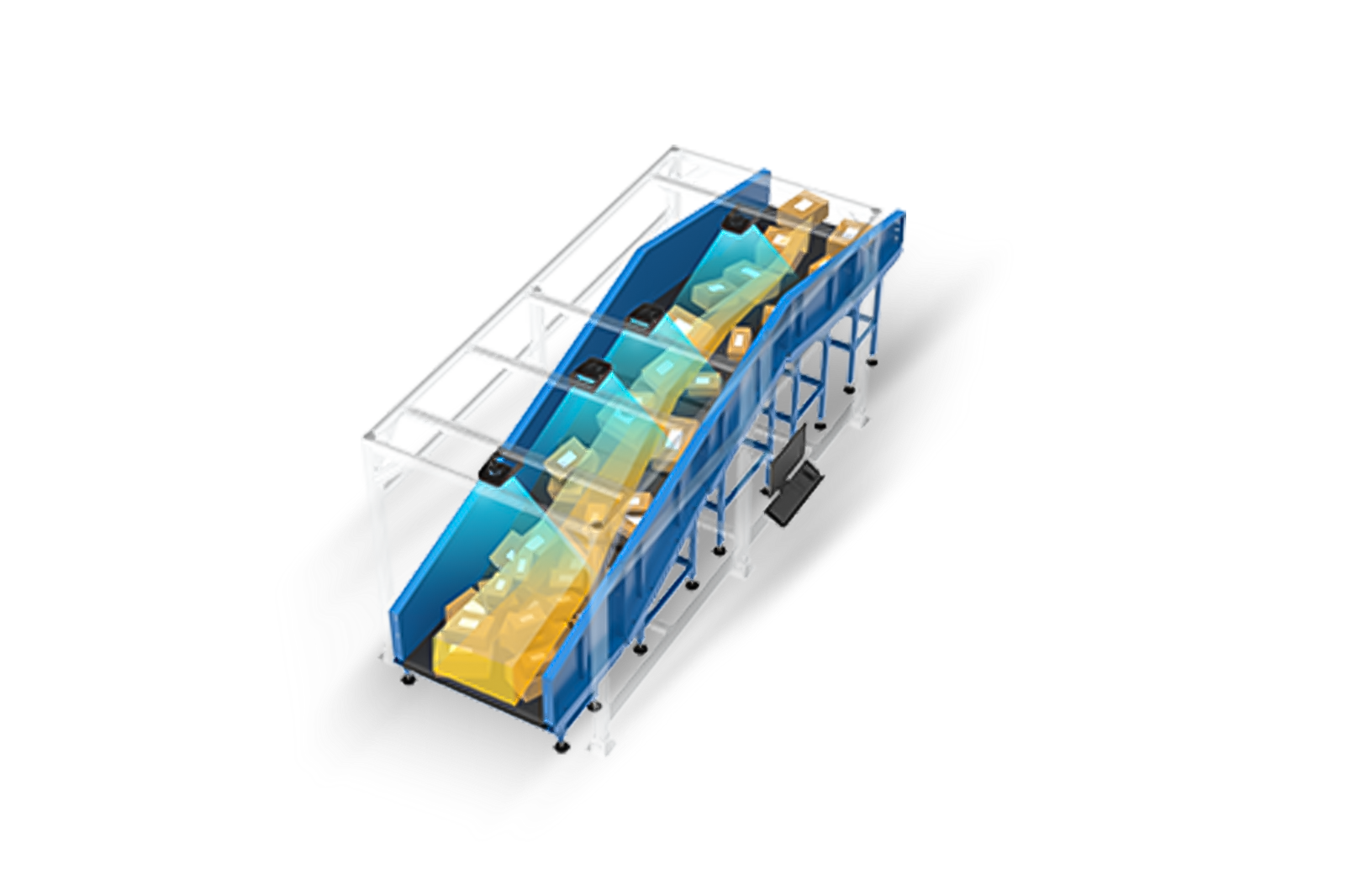

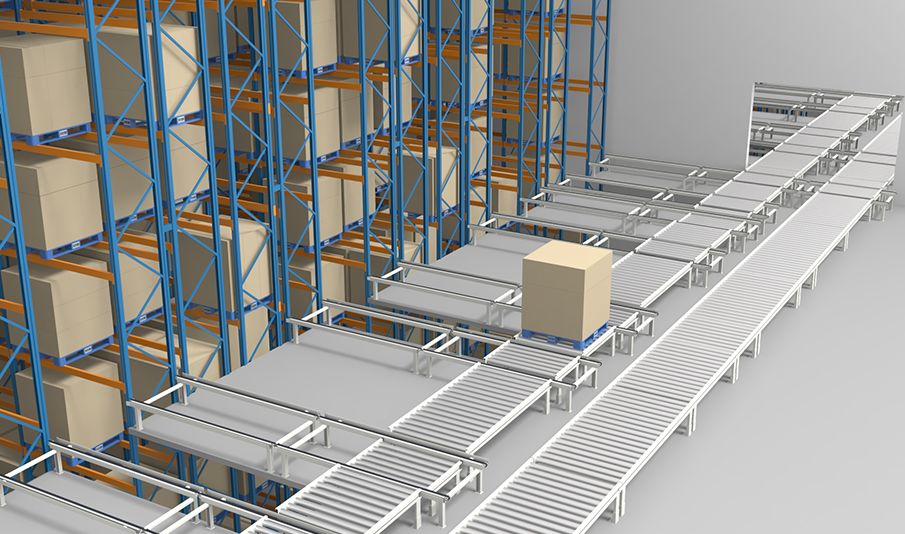

Aligning, Consolidation and Outbound Processes

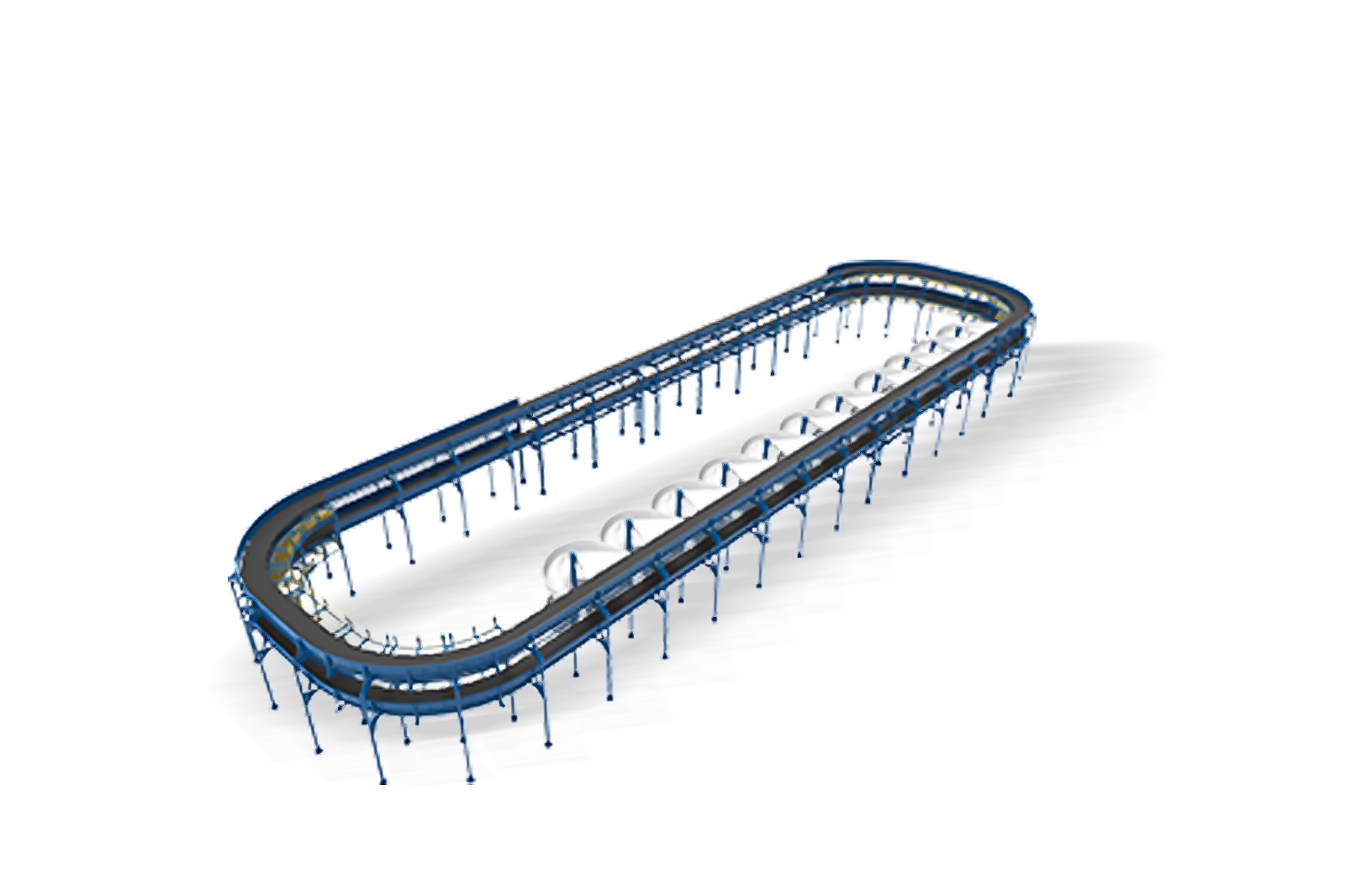

In the aligning, consolidation and outbound processes, the outbound stacker crane takes out the goods in the storage area to the infeed aligning and consolidation area where the goods are consolidated based on the formula order, and then conveys goods to the infeed buffer lane for the outbound process.

Main products: Multi-shuttle, AGV, Sorter, and Floor Chain System

Efficiently create intelligent logistics equipment