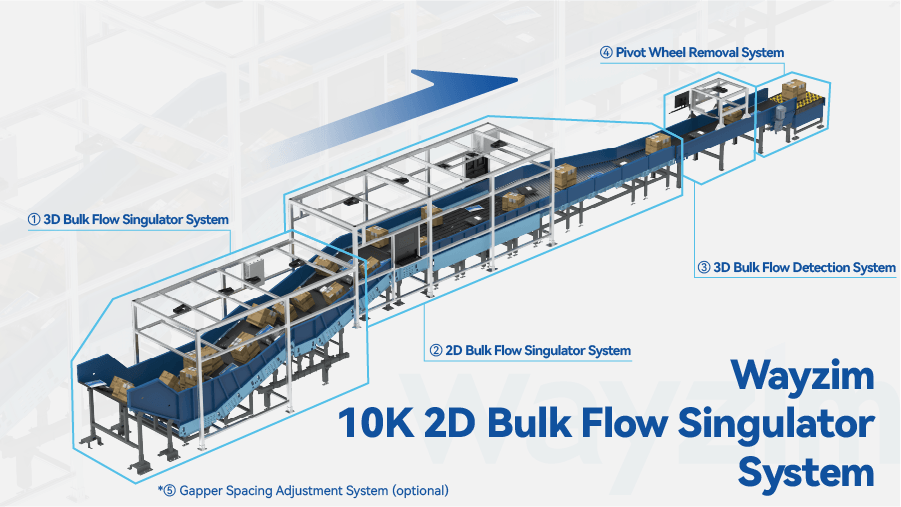

With the rapid growth of the express delivery and e-commerce business, parcel sorting exhibits a trend towards smaller parcel size, greater parcel density, and higher sorting speed. Manual sorting and infeed are inefficient and often create uncertainties in complex situations, such as workload fluctuations during peak hours and mixed parcel codes. Wayzim’s 10K 2D Bulk Flow Singulator System is developed to tackle the challenge of 3D flow singulation faced by the industry. With a maximum sorting rate of 10,000 pph, this system helps provide a stable and efficient infeed environment for the intelligent sorting system through high-precision recognition, singulating/gapping, and orderly arranging of parcels.

The 10K 2D Bulk Flow Singulator System consists of five subsystems, the 3D Bulk Flow Singulator System, 2D Bulk Flow Singulator System, 3D Bulk Flow Detection System, Pivot Wheel Removal System, and Gapper Spacing Adjustment System (optional). The 2D Bulk Flow Singulator System is composed of a Horizontal 2D Bulk Flow Singulator, an Alignment Conveyor, a Position Detector, and an Industrial All-in-One Camera. The entire line can operate stably at a speed of 2 m/s.

3D Bulk Flow Singulator System: 3D Singulation of Overlaps

After parcels are conveyed to the 3D bulk flow singulation area by belts, the system determines the parcel positions and types through cameras, sets the parcel spacing threshold based on site requirements, and starts the intelligent control system for 3D singulation of overlaps.

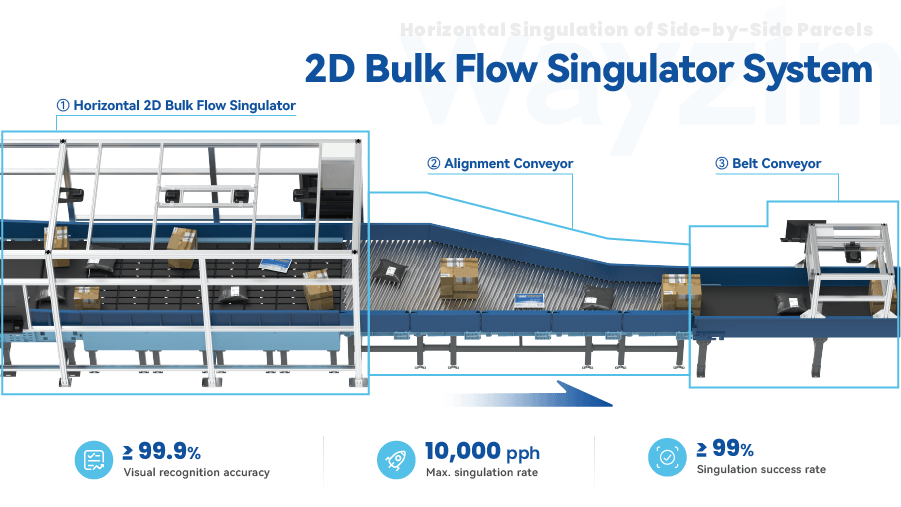

2D Bulk Flow Singulator System: Horizontal Singulation of Side-by-Side Parcels

After 3D singulation, parcels are conveyed to the horizontal singulation area, where the cameras collect parcel images in real time, and the vision system analyses parcel distribution within the singulation area and controls the belt speed of each 2D singulation module according to the singulation policy to singulate side-by-side parcels.

- Horizontal 2D Bulk Flow Singulator The Industrial All-in-One Camera collects images and uploads them to the industrial PC for algorithm-based image processing. Then, the singulator outputs the number and coordinates of parcels, and controls the belt speed of each 2D singulation module according to the singulation policy to singulate side-by-side parcels.

- Alignment Conveyor After horizontal singulation, parcels reach the Alignment Conveyor, which consists of several non-powered rollers, and move perpendicular to the rollers until they reach one side of the Alignment Conveyor and form a stable 2D bulk flow.

- Belt Conveyor The SmartlogitecX Belt Conveyor at the end of the 2D Bulk Flow Singulator System consists of a frame, legs, rollers, a belt, and a power system. It connects the Alignment Conveyor to the subsequent belt conveyor line.

3D Bulk Flow Detection System: Non-conveyable Parcel Detection

After leaving the Alignment Conveyor, the 2D bulk flow is conveyed to the Visual Detection System for parcel position detection. If two parcels are too close to each other, the system determines that they are stacked parcels (too close). If two parcels are overlapping, the system determines that they are stacked parcels (overlaps). Otherwise, the system determines that the parcels are normal and conveys them to the next sorting section.

Pivot Wheel Removal System: Return of Non-conveyable Parcels

Stacked parcels detected by the 3D Bulk Flow Detection System are removed by SmartlogitecX pivot wheels and returned for re-sorting.

As one of Wayzim’s core innovations, the 2D Bulk Flow Singulator System will be showcased at Parcel+Post Expo 2025 in the Netherlands. We warmly welcome you to visit our booth and discuss how this technology can support your logistics needs.