An “automated storage and retrieval system” (ASRS) represents a pivotal shift in modern warehouse management. As businesses grapple with increasing demand, rising labour costs, and the need for greater efficiency, traditional warehousing methods are proving insufficient. This advanced technology optimises space, streamlines operations, and significantly enhances productivity, fundamentally altering how goods are stored and accessed.

The warehouse industry faces unprecedented challenges. E-commerce growth has accelerated order volumes while customer expectations for faster delivery continue to rise. Meanwhile, labour shortages and increasing operational costs squeeze profit margins. In this environment, automation isn’t just an advantage—it’s becoming essential for survival.

What is an Automated Storage and Retrieval System ASRS

An automated storage and retrieval system is a computer-controlled solution that automatically places and retrieves items from specific storage locations within a warehouse. Unlike traditional manual storage methods that rely on human workers and forklifts, ASRS systems use sophisticated machinery and software to handle inventory movement with minimal human intervention.

The core components of modern ASRS systems include high-density storage racks, automated retrieval machines such as cranes or shuttle robots, and advanced warehouse control software that orchestrates all operations. These elements work in concert to create a seamless flow of materials throughout the facility.

While manual warehouses depend on workers physically locating, picking, and transporting items—often covering thousands of steps per shift—automated storage transforms this process entirely. The shift from manual to automated operations represents more than just technological advancement; it’s a fundamental reimagining of warehouse efficiency.

Key Benefits of ASRS for Modern Warehouses

Implementing automated storage solutions addresses multiple operational challenges simultaneously. These systems don’t just improve one aspect of warehouse operations—they create a ripple effect of positive changes throughout the entire supply chain. An automated storage and retrieval system can reduce operating costs by up to 40% while dramatically improving service levels.

Maximising Space Efficiency

Traditional warehouses typically utilise only 30-40% of their available vertical space. In contrast, an ASRS warehouse can leverage heights of 40 feet or more, transforming previously unused air space into productive storage capacity. This vertical optimisation is particularly valuable in urban areas where real estate costs continue to climb.

The ASRS racking system employs narrow aisles and eliminates the wide pathways required for forklift operation. By condensing the storage footprint, businesses can store the same inventory in half the space—or double their capacity without expanding their facility. This high-density approach often delays or eliminates the need for costly warehouse expansions.

Boosting Operational Productivity

Automated storage systems revolutionise productivity metrics across the board. Where manual picking might achieve 60-80 picks per hour, automated systems can reach 200-400 picks per hour or more. This dramatic improvement stems from eliminating travel time, search time, and human limitations.

The system knows exactly where every item is located and retrieves it via the most efficient path. Workers no longer waste time walking through aisles or searching for misplaced inventory. Instead, the system brings items directly to ergonomic workstations where operators can focus on value-added tasks like quality control and order verification.

Enhancing Inventory Accuracy and Control

Human error in inventory management costs businesses billions annually through misplaced items, incorrect counts, and shipping mistakes. ASRS virtually eliminates these errors by maintaining precise control over every movement within the warehouse.

Real-time tracking provides instant visibility into inventory levels, locations, and movement history. This accuracy extends beyond simple counting—the system can track expiration dates, lot numbers, and serial numbers automatically. The result is near-perfect inventory accuracy rates of 99.9% or higher, reducing stock outs, overstocking, and customer complaints.

Improving Worker Safety

Warehouse work traditionally ranks among the most dangerous occupations, with high rates of injuries from lifting, falling, and equipment accidents. ASRS systems dramatically reduce these risks by eliminating many hazardous tasks entirely.

Workers no longer need to climb ladders, operate forklifts in congested areas, or manually lift heavy items. The automated system handles all dangerous movements while presenting items at comfortable working heights. This safer environment not only protects workers but also reduces insurance costs and workers’ compensation claims.

Types of Automated Storage and Retrieval Systems

The diversity of ASRS technologies ensures solutions for virtually any warehouse application. From small parts to full pallets, each system type offers unique advantages for specific operational needs.

Vertical Lift Modules VLM

A SmartlogitecX vertical lift module consists of two columns of trays with an automated extractor mechanism in the centre. When an item is requested, the system automatically locates the correct tray and presents it at an ergonomic access window. This enclosed design provides exceptional security while maximising vertical space utilisation.

VLMs excel in storing small to medium-sized parts, tools, and components. Manufacturing facilities use them for managing thousands of SKUs in minimal floor space. The system’s ability to vary tray heights based on stored items ensures optimal space usage for irregularly shaped products.

Vertical and Horizontal Carousels

The vertical carousel storage system operates like a Ferris wheel, rotating shelves or carriers vertically to bring items to an access point. This design works particularly well for high-speed picking of small parts and components. Many facilities implement multiple vertical carousels with software that coordinates picks across units, dramatically improving throughput.

A horizontal carousel storage system consists of bins rotating on an oval track at floor level. These systems excel in batch picking operations where multiple orders can be fulfilled simultaneously. The horizontal configuration allows for longer carriers, making them ideal for storing items like garments, hardware, or electronic components.

The Kardex vertical carousel represents a premium solution in this category, offering advanced features like automatic height detection and integrated inventory management software. These systems can reduce picking times by up to 65% compared to static shelving.

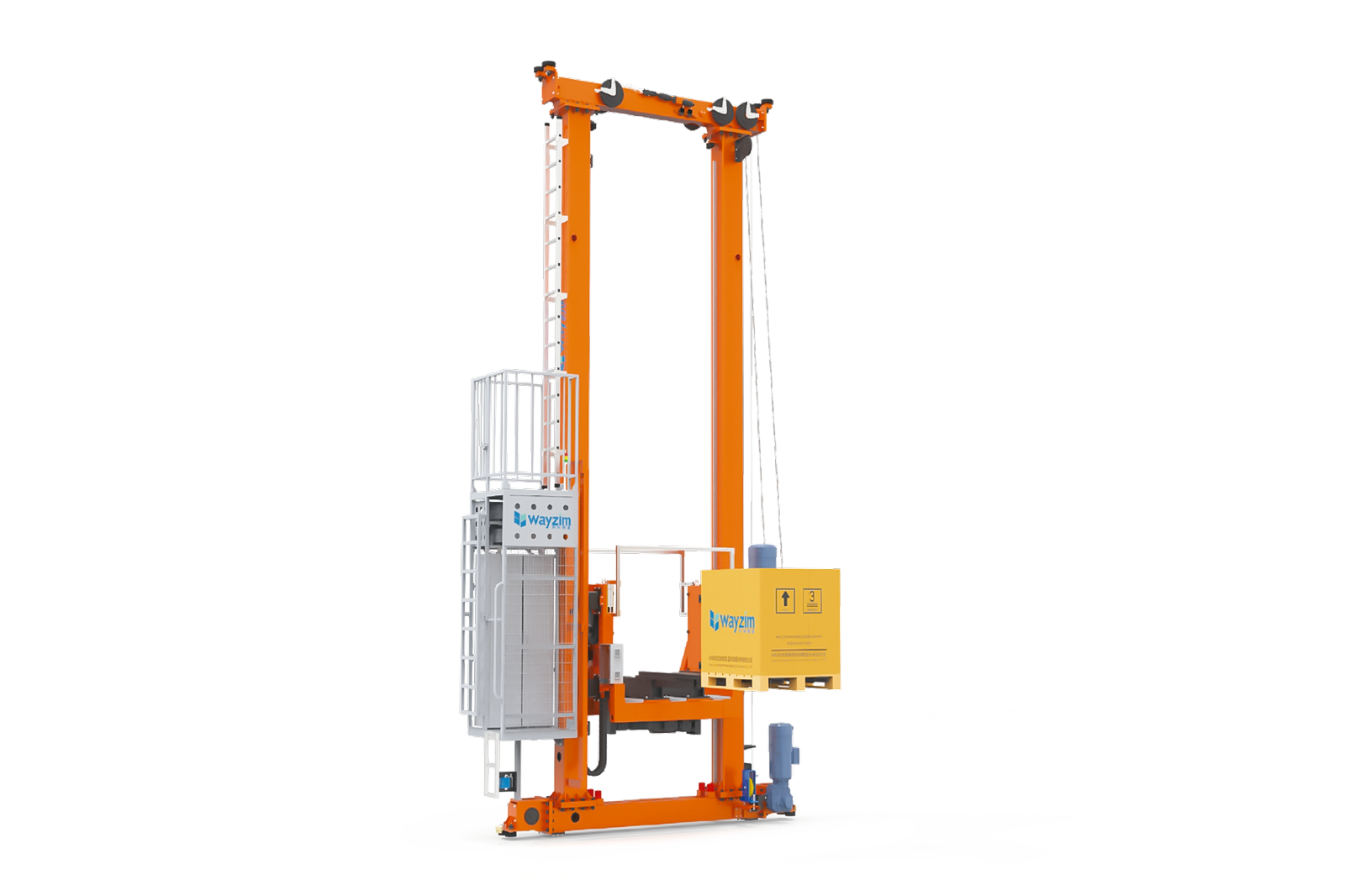

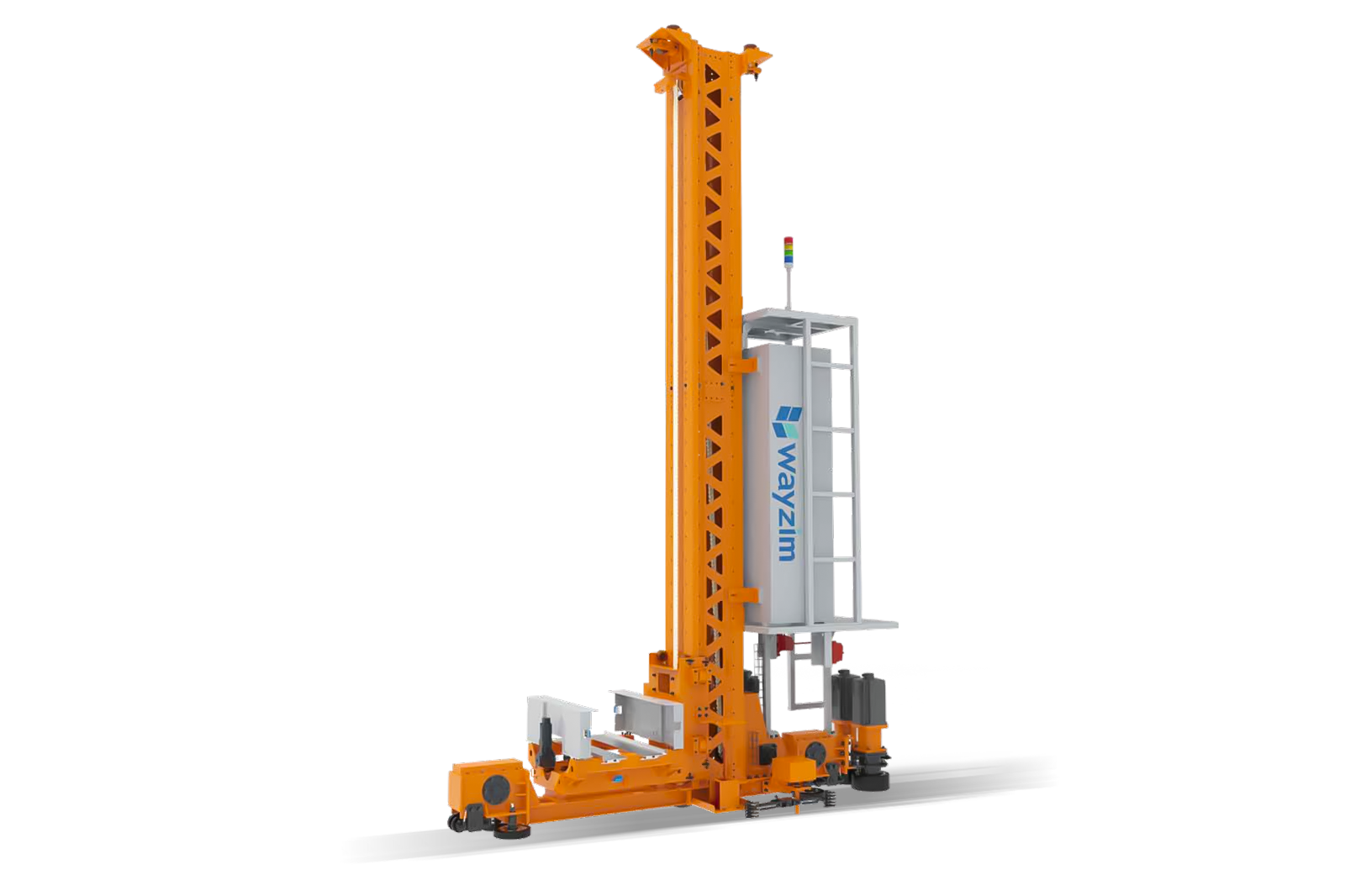

Unit Load and Mini Load Systems Pallet Based

An automated pallet storage and retrieval system handles the heaviest loads in warehouse operations. Using automated cranes or shuttle systems, these solutions can manage pallets weighing several tons, storing them in racks reaching 100 feet or higher. They’re essential for high-volume distribution centres handling thousands of pallets daily.

Mini-load systems apply similar technology to smaller loads like cases, totes, or cartons. These systems bridge the gap between item-level and pallet-level automation, offering flexibility for various package sizes. The combination of high density and rapid retrieval makes them ideal for e-commerce fulfilment and manufacturing operations.

Implementing an ASRS System Considerations

Successfully implementing ASRS technology requires careful planning and strategic decision-making. The transformation from manual to automated operations impacts every aspect of warehouse management, from workflow design to staff training.

Assessing Your Warehouse Needs

Before selecting any ASRS system warehouse solution, conduct a comprehensive analysis of your current operations. Document inventory characteristics including size ranges, weights, and handling requirements. Analyse throughput patterns to identify peak periods and seasonal variations.

Consider your physical constraints carefully. Ceiling height, floor load capacity, and column spacing all influence system selection. Don’t forget to account for future growth—the right system should accommodate your needs for the next 10-15 years, not just today’s requirements.

Budget considerations extend beyond initial investment. Factor in installation costs, training requirements, maintenance contracts, and potential facility modifications. While the upfront investment may seem substantial, most businesses achieve ROI within 2-4 years through labour savings and efficiency gains.

Choosing the Right ASRS Provider

Selecting among automated storage and retrieval system companies requires evaluating multiple factors beyond price. Look for providers with proven experience in your industry—a company specialising in automotive parts may not be the best choice for food distribution.

Evaluate technological capabilities carefully. The best providers offer flexible solutions that integrate seamlessly with your existing warehouse management system. They should provide comprehensive support including system design, installation, training, and ongoing maintenance.

Consider the provider’s long-term stability and support infrastructure. Your ASRS represents a significant investment that should operate reliably for decades. Choose a partner with a strong track record, local support presence, and commitment to ongoing innovation.

Conclusion

An automated storage and retrieval system represents more than just warehouse equipment—it’s a strategic investment in operational excellence. The benefits extend throughout your organisation, from improved customer satisfaction through accurate, rapid order fulfilment to enhanced employee safety and satisfaction.

As market pressures intensify and customer expectations continue rising, SmartlogitecX automated storage solutions provide the competitive edge necessary for success. The question isn’t whether to automate, but how quickly you can implement these transformative technologies to stay ahead of the competition.

The future of warehousing is automated, efficient, and intelligent. By embracing ASRS technology today, you position your operation for tomorrow’s challenges while immediately realising benefits in productivity, accuracy, and profitability.