Introduction

In today’s competitive marketplace, businesses face mounting pressure to optimise their warehouse operations while managing rising labour costs and space constraints. Traditional storage methods, characterised by manual picking, conventional shelving, and forklift operations, are increasingly struggling to meet modern demands for speed and accuracy. Enter SmartlogitecX ASRS systems – automated storage and retrieval solutions that are revolutionising how companies manage their inventory.

This comprehensive comparison explores why forward-thinking businesses are abandoning traditional storage methods in favor of automated storage technology. We’ll examine the key differences, benefits, and considerations that make this transition not just smart, but essential for staying competitive in today’s market.

Understanding Traditional Warehouse Storage

Traditional warehouse storage relies heavily on manual processes and human decision-making. Workers navigate aisles with forklifts or picking carts, retrieving items from static shelving or pallet racks. This approach depends on experienced staff who know the warehouse layout and can locate products based on memory or paper-based systems.

While traditional storage has served businesses for decades, it comes with inherent limitations. Space utilisation rarely exceeds 60% of available vertical height due to safety concerns and equipment restrictions. Human error rates in picking and placing average 1-3%, leading to inventory discrepancies and customer dissatisfaction. Additionally, the labour-intensive nature of these operations results in higher ongoing costs and increased workplace injury risks.

What Are ASRS Systems

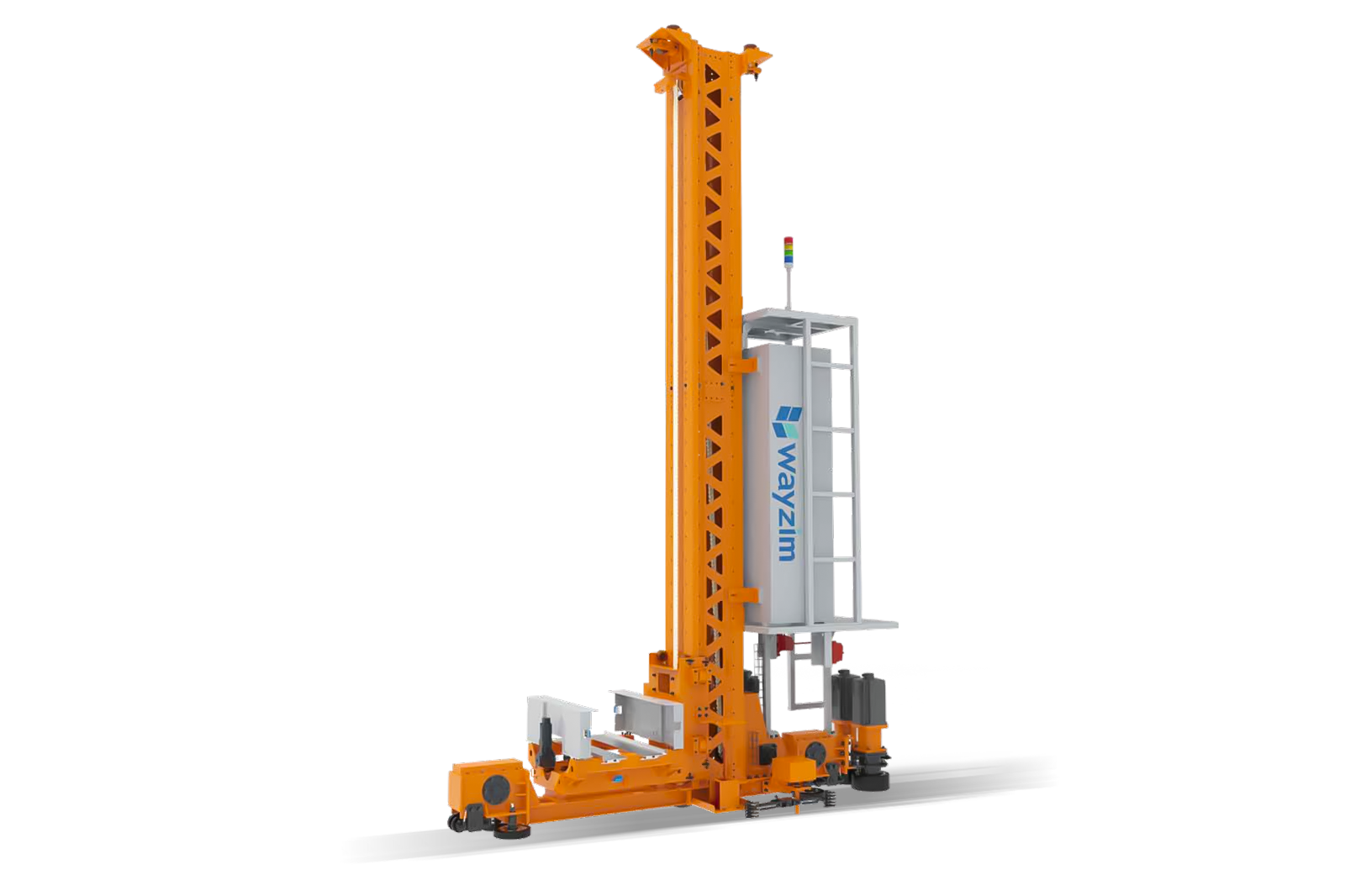

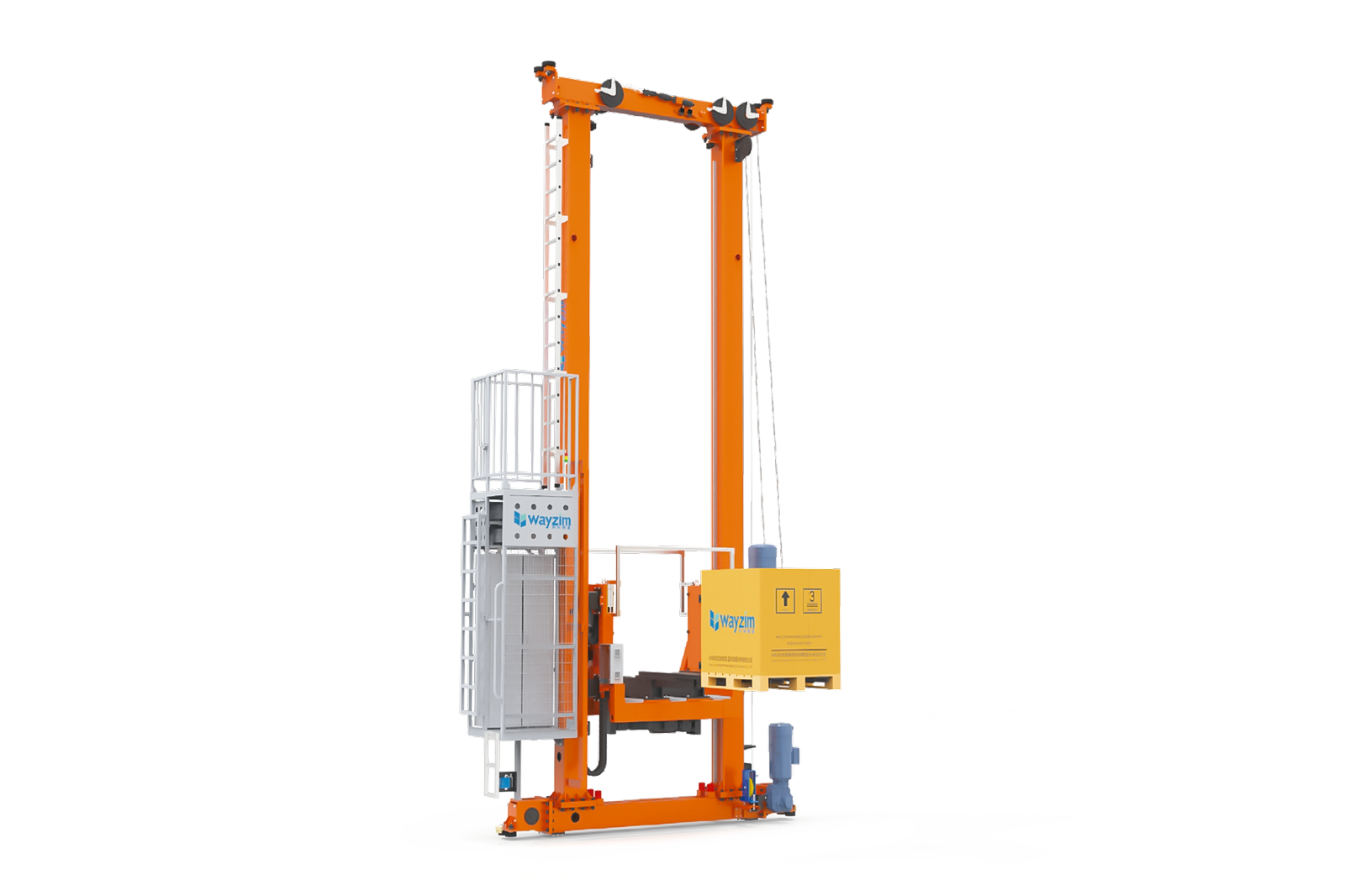

ASRS systems, or automated storage and retrieval systems, represent a paradigm shift in warehouse management. These sophisticated automated storage systems combine mechanical equipment with intelligent software to store and retrieve items without direct human intervention. At their core, these automated storage retrieval systems consist of storage structures, automated machines like cranes or shuttles, and sophisticated warehouse management software.

The beauty of an automated storage and retrieval system lies in its precision and consistency. Computer-controlled mechanisms navigate predetermined paths, retrieving specific items with millimeter accuracy. This automation eliminates the guesswork and physical strain associated with traditional methods while dramatically improving throughput and accuracy rates.

ASRS Systems Versus Traditional Storage: A Direct Comparison

Understanding the stark differences between ASRS systems vs traditional storage helps businesses make informed decisions about their warehouse future. Let’s examine how these approaches compare across critical operational metrics.

Space Utilisation

Traditional storage typically utilises only 40-60% of available vertical space, limited by forklift reach and safety regulations. Wide aisles consume valuable floor space, reducing overall storage density. In contrast, vertical automated storage systems can utilise up to 85% of available height, with some ASRS racking systems reaching 100+ feet tall.

ASRS racking eliminates the need for wide forklift aisles, replacing them with narrow equipment tracks. This optimisation can increase storage capacity by 50-80% within the same footprint, making every square foot count.

Operational Efficiency and Throughput

Manual operations average 50-100 lines picked per hour per worker, with significant variability based on worker experience and fatigue. ASRS automation delivers consistent performance, with automated storage systems processing 200-800 lines per hour depending on configuration. This reliability enables precise production planning and improved customer service levels.

Accuracy and Inventory Management

Human error in traditional warehouses leads to inventory accuracy rates of 95-98% at best. An automated storage retrieval system achieves accuracy rates exceeding 99.9% through SmartlogitecX barcode scanning and computer-controlled placement. Real-time inventory tracking provides instant visibility into stock levels, enabling better purchasing decisions and reduced safety stock requirements.

Safety and Ergonomics

A warehouse automated storage and retrieval system removes workers from dangerous zones, eliminating risks associated with falling objects, forklift collisions, and repetitive strain injuries. This improvement in workplace safety reduces insurance costs and improves employee retention.

Cost Implications and Return on Investment

While ASRS systems require significant upfront investment ($500,000 to $5 million depending on scale), automated storage solutions deliver compelling long-term savings. Labour cost reductions of 50-70%, combined with decreased product damage and improved space utilisation, typically generate ROI within 2-4 years.

Key Benefits of Switching to ASRS

Smart businesses recognise that implementing an ASRS warehouse goes beyond simple automation – it’s about transforming operational capabilities. The automated storage and retrieval system becomes a strategic advantage that drives competitive differentiation.

Maximizing Warehouse Space

Vertical automated storage systems allow businesses to grow within their existing facilities. By utilising previously unreachable vertical space, companies can double or triple storage capacity without expensive relocations or expansions. An ASRS system warehouse configuration adapts to irregular spaces, maximising every available cubic foot.

Boosting Productivity and Reducing Labor Costs

ASRS automation enables one operator to accomplish what previously required 3-5 workers. Staff can focus on value-added activities like quality control and customer service rather than repetitive picking tasks. Productivity gains of 200-300% are common, with 24/7 operation capability further amplifying output.

Enhancing Inventory Accuracy and Control

Precise tracking eliminates lost inventory and reduces shrinkage to near zero. Real-time visibility enables just-in-time inventory strategies, reducing carrying costs while maintaining service levels.

Improving Worker Safety

Automation removes employees from hazardous environments, creating safer, more comfortable working conditions. This improvement boosts morale and reduces costly workers’ compensation claims.

Choosing the Right ASRS System for Your Business

Selecting among automated storage and retrieval system companies requires careful evaluation of your specific needs. Consider factors including product characteristics, throughput requirements, available space, and integration with existing systems. Leading automated storage solutions providers offer consultation services to help identify optimal configurations.

Types of ASRS Systems

Different ASRS technologies suit various applications. Vertical Lift Modules excel at storing small parts with high SKU counts. Horizontal carousels work well for batch picking operations. Shuttle systems provide flexibility for changing inventory profiles. An automated pallet storage and retrieval system handles full pallet loads efficiently, ideal for distribution centers. Each ASRS system warehouse configuration offers unique advantages depending on operational requirements.

Frequently Asked Questions

1.What exactly is an ASRS system?

An ASRS system automates the storage and retrieval of items using computer-controlled equipment, eliminating manual handling while improving speed and accuracy.

2.How do ASRS systems save space compared to traditional storage?

ASRS systems utilise vertical space more efficiently and require narrower aisles, increasing storage density by 50-80% within the same footprint.

3.What are the primary benefits of implementing ASRS automation in a warehouse?

Key benefits include increased storage capacity, improved accuracy, reduced labour costs, enhanced safety, and faster order fulfilment.

4.Can ASRS systems integrate with existing warehouse management systems?

Yes, modern ASRS solutions are designed to integrate seamlessly with existing WMS and ERP systems through standard interfaces.

5.What is the typical return on investment for an ASRS installation?

Most businesses achieve ROI within 2-4 years through labor savings, improved accuracy, and increased throughput.

6.Are ASRS systems suitable for all types of businesses and industries?

While particularly beneficial for high-volume operations, ASRS solutions can be scaled for various business sizes and industries.

7.How do automated pallet storage and retrieval systems work?

These systems use automated cranes or shuttles to store and retrieve full pallets from high-density racking structures based on computer commands.

8.What factors should be considered when choosing an ASRS provider?

Evaluate experience, system reliability, service support, integration capabilities, and total cost of ownership.

9.Do ASRS systems improve warehouse safety?

Yes, automation significantly reduces workplace injuries by eliminating manual handling and removing workers from hazardous areas.

10.What are the different types of automated storage solutions available?

Options include vertical lift modules, carousels, shuttle systems, mini-load, and unit-load ASRS, each suited for different applications.

11.How does an ASRS system handle inventory tracking and accuracy?

Using barcode scanning and computer-controlled placement, ASRS maintains 99.9%+ inventory accuracy with real-time tracking.

12.Is “automated storage” the same as “ASRS”?

While often used interchangeably, automated storage is a broader term that includes ASRS and other automation technologies.

The transition from traditional storage to ASRS systems represents more than a technology upgrade – it’s a strategic decision that positions businesses for long-term success. As labour costs rise and customer expectations increase, the question isn’t whether to automate, but how quickly you can make the switch.