Modern Third-Party Logistics providers face unprecedented pressure to deliver faster, more accurate service whilst managing tighter margins. Recent studies demonstrate that AI-driven job optimisation can boost operational efficiency by up to 58%, yet many 3PLs continue to rely on manual processes that simply cannot keep pace with evolving client demands. The convergence of rising consumer expectations, persistent labour shortages, and the imperative to reduce operational costs has positioned warehouse automation for 3PLs as a strategic necessity rather than a competitive advantage. This shift represents more than technological adoption—it’s a fundamental reimagining of how logistics operations can scale efficiently whilst maintaining the accuracy and speed that modern commerce demands. This article examines the transformative benefits that 3PL automation delivers, from substantial cost reductions to enhanced client satisfaction, demonstrating why SmartlogitecX automated warehouse solutions have become essential infrastructure for forward-thinking logistics providers.

Gaining a Competitive Edge with Major Cost Reductions

The financial case for implementing warehouse automation solutions begins with immediate, measurable reductions in operational expenses that compound over time. For 3PL operators managing multiple client portfolios, these savings translate directly to improved margins and competitive pricing structures that can attract new business whilst retaining existing relationships.

How Automated Technology Reduces High Labour Costs

Labour represents one of the largest expense categories for any logistics operation, and warehouse automation solution providers have developed sophisticated technologies that fundamentally reshape this cost structure. Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) operate continuously without breaks, eliminating the wage expenses, training investments, and turnover costs associated with manual picking and transport tasks. SmartlogitecX has observed that 3PLs implementing these technologies typically reallocate human workers to higher-value supervisory and client management roles, transforming labour from a variable cost center into a strategic asset. This redeployment doesn’t eliminate jobs—it elevates them, creating opportunities for employees to develop skills in system management and customer service that benefit both the organisation and the individual.

The Impact of Fewer Errors on Your Bottom Line

Beyond labour savings, automation delivers substantial financial benefits through error reduction, a factor that significantly impacts profitability through multiple channels. Manual picking operations typically achieve 99% accuracy at best, meaning one order in every hundred contains mistakes that trigger costly returns, reverse logistics processes, and potential damage to client relationships. Automated systems utilising pick-to-light technology and intelligent sortation achieve accuracy rates exceeding 99.9%, virtually eliminating the expense of correcting mistakes. For a 3PL processing 10,000 orders monthly, this accuracy improvement prevents approximately 900 errors annually, with each error potentially costing $50-$150 in direct expenses and immeasurable reputational damage. The cumulative savings from reduced errors often justify automation investments within 18-24 months.

Enhancing Client Satisfaction and Retention

Operational excellence forms the foundation of client satisfaction in the competitive 3PL landscape, where service level agreements (SLAs) function as binding commitments that determine contract renewals and business growth. Warehouse automation empowers providers to consistently meet and exceed these agreements, transforming service delivery from a challenge into a reliable competitive differentiator.

Faster Delivery Times and Fulfilment Speed

Speed has evolved from a desirable attribute to a mandatory requirement in modern logistics, particularly as e-commerce clients demand same-day and next-day delivery capabilities. Automated conveyors, sortation systems, and robotic picking technologies compress the fulfilment cycle by eliminating the bottlenecks inherent in manual operations. Where traditional order processing might require 45-60 minutes from receipt to dispatch, SmartlogitecX automated facilities can complete the same process in 10-15 minutes, enabling later order cut-off times and faster customer delivery. This acceleration creates tangible value for clients whose own customers increasingly expect Amazon-level service standards, regardless of which retailer they’re purchasing from.

The Power of Accuracy for Building Trust

Consistent accuracy represents the bedrock of client trust, particularly for 3PLs managing multiple brands with distinct quality expectations. A sophisticated Warehouse Management System (WMS) provides real-time visibility into inventory levels, order status, and fulfilment accuracy, creating transparency that strengthens client relationships. When clients can access live data showing 99.9% order accuracy and real-time tracking capabilities, they develop confidence in the 3PL’s operational competence. This transparency proves especially valuable during peak seasons or product launches, when clients need assurance their orders are being processed correctly. Fewer shipping mistakes translate directly to reduced customer service inquiries, lower return rates, and ultimately, higher client retention rates that fuel sustainable business growth.

Achieving Flawless Fulfilment with Improved Accuracy

Precision across every stage of the fulfilment cycle separates exceptional 3PL operations from merely adequate ones, and specific automation technologies have proven remarkably effective at eliminating the human error that plagues manual processes.

Automated Picking and Inventory Precision

Goods-to-person robotics, pick-to-light systems, and voice-directed picking each address different aspects of the accuracy challenge, but they share a common attribute: they reduce picking errors by 70-90% compared to traditional paper-based or RF scanning methods. SmartlogitecX Automated Storage and Retrieval Systems (AS/RS) work in concert with robust warehouse management systems to maintain real-time inventory accuracy, preventing the stockouts and overstock situations that erode client confidence and tie up working capital. These technologies employ multiple verification steps at each stage—confirming the correct item, validating quantities, and verifying packaging requirements—creating a systematic approach to accuracy that manual processes simply cannot replicate. For 3PLs managing inventory for multiple clients with strict quality requirements, this level of precision isn’t just beneficial—it’s essential for maintaining contracts and supporting business development efforts.

Future Proofing Your Operations with Enhanced Scalability

Forward-thinking 3PL operators recognise that automation represents more than an efficiency tool—it’s a strategic asset that enables sustainable growth without proportional increases in overhead costs or operational complexity.

Managing Peak Seasons and Changing Demand

Seasonal demand fluctuations create significant challenges for traditional warehouses, often requiring temporary staff increases that necessitate extensive recruitment, training, and onboarding processes during precisely the periods when management attention is most stretched. Automated warehouses handle these spikes with remarkable ease, as robotic systems can extend operating hours and increase throughput without hiring additional staff. Advanced AI and machine learning components analyse historical patterns and current trends to forecast demand accurately, enabling dynamic allocation of robotic resources to areas experiencing the highest volume. This flexibility proves invaluable during holiday seasons, promotional events, or unexpected demand surges, allowing SmartlogitecX clients to accept more business during peak periods rather than limiting intake due to capacity constraints.

Supporting Business Growth and Expansion

Scalability benefits extend beyond seasonal management to support fundamental business expansion. Automated systems allow 3PLs to onboard new clients and handle substantially higher order volumes without requiring proportional increases in facility space or workforce. This economic model makes expansion significantly less capital-intensive, enabling aggressive growth strategies that would be prohibitively expensive using traditional manual approaches. A 3PL might double their order volume by increasing automated equipment by 30-40%, a scaling efficiency that transforms the economics of business development and enables more competitive pricing for new clients.

Boosting Throughput with Unmatched Operational Efficiency

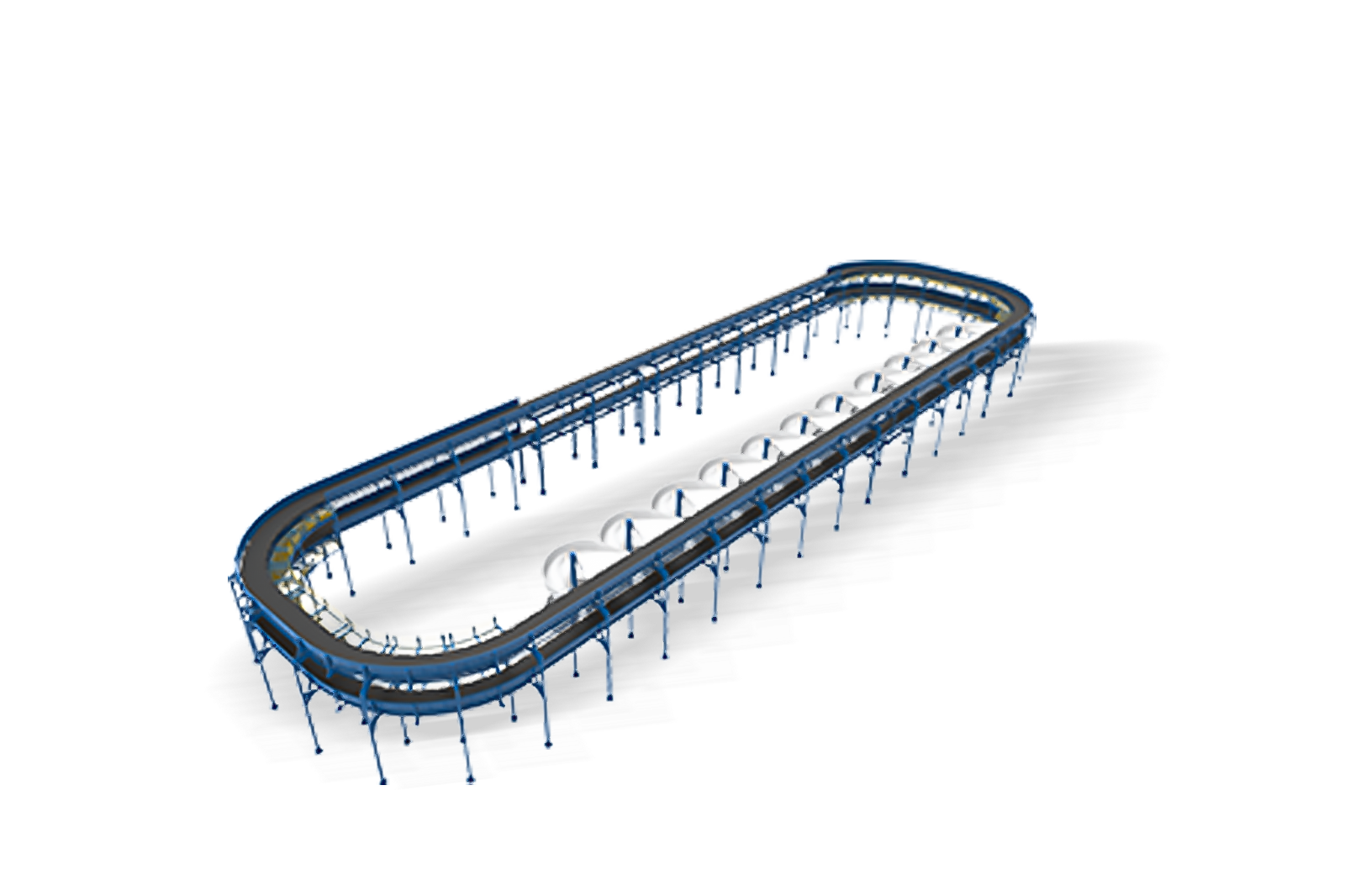

Warehouse automation solutions deliver dramatic improvements in throughput metrics that directly impact a 3PL’s capacity and revenue potential. Automated systems remove the bottlenecks that constrain manual operations, particularly the time workers spend travelling between picking locations and the inherent variability in human performance throughout shifts.

| Task | Manual Operation | Automated Operation | Efficiency Gain |

| Order Picking | 10-15 minutes | 2-3 minutes | ~80% Faster |

| Travel Time | 50-60% of picker’s time | Near 0% (Goods-to-Person) | Significant |

| Sorting & Packing | 3-5 minutes | 1-2 minutes | ~60% Faster |

These efficiency improvements compound throughout the day, enabling facilities to process 2-3 times more orders with similar square footage. The elimination of travel time through goods-to-person systems proves particularly transformative, as traditional operations dedicate the majority of labour hours to simply moving between locations rather than adding value through actual picking or packing activities.

Maximising Your Footprint Through Smart Space Optimisation

Industrial real estate costs continue rising globally, making space efficiency a critical economic consideration for 3PL operators managing multiple facilities or contemplating expansion.

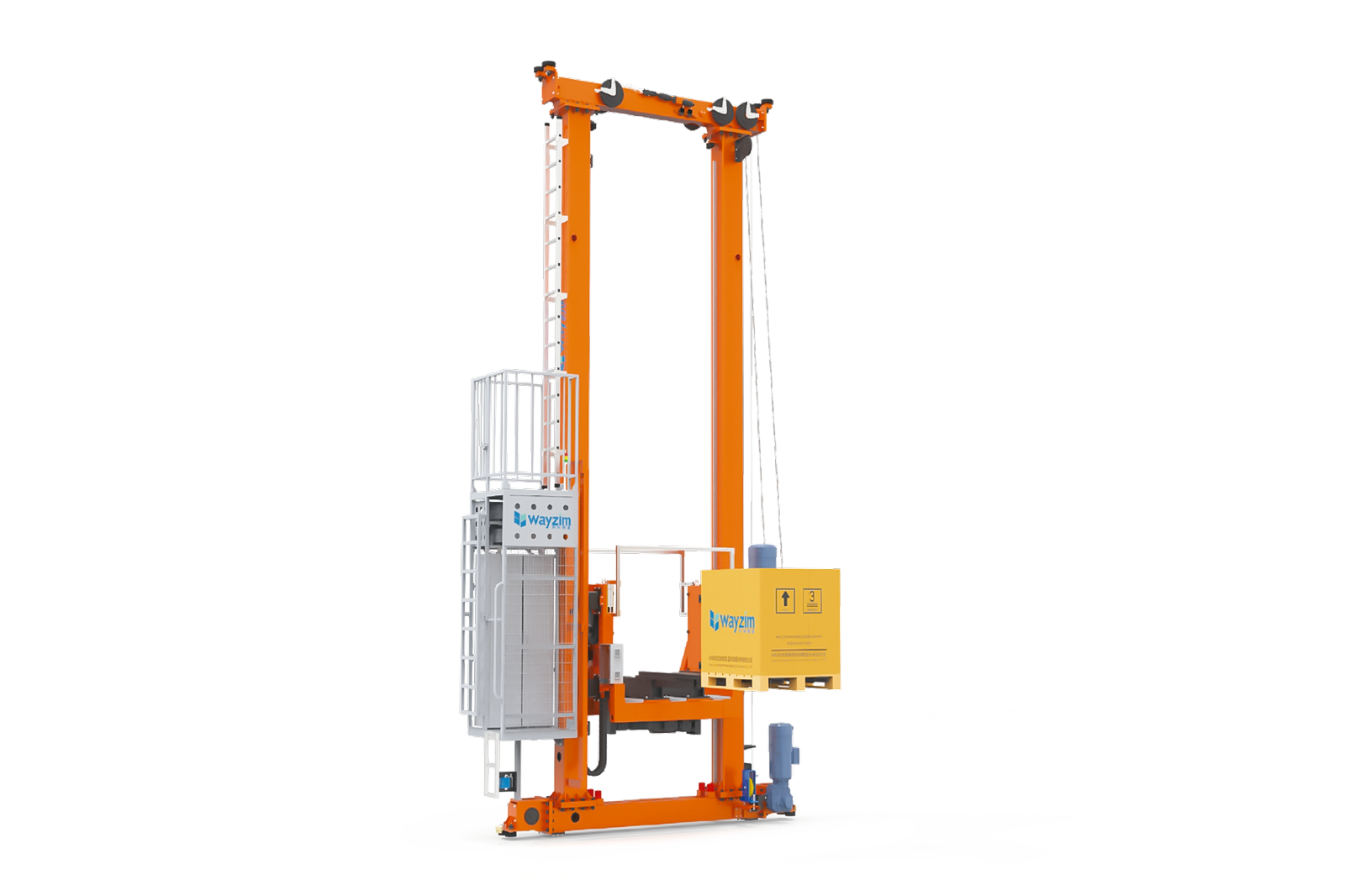

Leveraging Vertical Space with AS/RS

Automated Storage and Retrieval Systems fundamentally reimagine warehouse space utilisation by exploiting vertical dimensions that manual operations cannot safely or efficiently access. These systems routinely operate at heights of 30-40 feet, doubling or tripling storage capacity within the same footprint compared to traditional racking accessible by forklifts or manual pickers. For 3PLs operating in markets where warehouse space commands premium rates—potentially $10-15 per square foot annually—this increased density directly impacts the bottom line by deferring or eliminating the need for additional facilities.

Reducing Aisle Width with Robotic Systems

AGVs and robotic shuttle systems operate effectively in aisles as narrow as 1.5 meters, compared to the 3-4 meter widths required for forklift operations. This seemingly modest reduction converts substantial square footage from unproductive aisle space into revenue-generating storage capacity. In a 100,000 square foot facility, optimising aisle width can recover 15,000-20,000 square feet for additional storage, effectively creating the equivalent of a substantial facility expansion without construction costs or additional rent.

Creating a Safer Workplace with Automated Systems

Workplace safety represents both a moral imperative and an economic consideration, as workplace injuries generate substantial costs through workers’ compensation, lost productivity, and regulatory compliance. Warehouse automation contributes to dramatically safer working environments by removing humans from the most dangerous tasks. Forklift accidents, heavy lifting injuries, and repetitive strain disorders—the three leading causes of warehouse injuries—diminish substantially when robots handle material transport and repetitive picking motions. Employees transition to supervisory and quality control roles that eliminate the physical strain associated with manual warehousing whilst maintaining meaningful employment. This transformation doesn’t just prevent injuries; it creates more satisfying, sustainable careers that reduce turnover and improve workforce quality.

Getting Started with Your 3PL Automation Journey

The benefits outlined—cost savings, enhanced client satisfaction, improved accuracy, operational scalability, increased efficiency, optimised space utilisation, and superior safety—collectively demonstrate that warehouse automation has evolved from an optional enhancement to a competitive requirement for 3PL providers. SmartlogitecX recommends that operators considering automation begin with a comprehensive operational audit to identify specific bottlenecks and quantify potential improvements. Many providers find that implementing a sophisticated Warehouse Management System represents an effective entry point, delivering immediate visibility improvements and data-driven decision-making capabilities whilst establishing the technological foundation for subsequent automation investments. Consulting with experienced warehouse automation companies ensures that solutions align with specific operational requirements, client needs, and growth trajectories, transforming automation from a technology purchase into a strategic partnership that supports long-term success.

Frequently Asked Questions

1.What are the main financial benefits of automating a 3PL warehouse?

The primary financial benefits include substantial labour cost reductions through 24/7 robotic operations, elimination of error-related expenses that can cost $50-150 per incident, optimised space utilisation that defers facility expansion, and improved throughput enabling revenue growth without proportional cost increases. Most 3PLs achieve positive ROI within 18-36 months.

2.How quickly can a 3PL see a return on investment (ROI) from automation?

ROI timelines vary based on implementation scope and current operational efficiency, but typical deployments achieve positive returns within 18-24 months for comprehensive systems or 12-18 months for targeted solutions like automated picking. High-volume facilities with significant labour costs often see faster returns.

3.Will automation replace all our warehouse workers?

Automation transforms rather than eliminates jobs. Whilst repetitive manual tasks shift to robots, facilities require skilled workers for system supervision, maintenance, exception handling, and client services. Many 3PLs find automation enables them to offer better-quality jobs whilst addressing labour shortage challenges.

4.How does automation help manage the demands of e-commerce clients?

E-commerce clients require rapid fulfilment, extended operating hours, and exceptional accuracy. Automated systems deliver all three, processing orders 70-80% faster than manual operations whilst maintaining 99.9%+ accuracy rates and enabling flexible capacity scaling during promotional events or seasonal peaks.

5.Can automated systems be integrated with our existing WMS?

Modern automation solutions are designed for integration with existing warehouse management systems through standard APIs and data protocols. Leading providers prioritise interoperability, ensuring automated equipment works seamlessly with established software infrastructure whilst enhancing rather than replacing existing technology investments.

6.What is the difference between an Automated Guided Vehicle (AGV) and an Autonomous Mobile Robot (AMR)?

AGVs follow fixed paths using magnetic strips or wires embedded in floors, whilst AMRs use sophisticated sensors and AI to navigate dynamically, avoiding obstacles and optimising routes in real-time. AMRs offer greater flexibility and easier deployment but typically cost more than AGVs.

7.How does automation improve inventory accuracy?

Automated systems eliminate manual data entry errors through barcode scanning, RFID verification, and weight confirmation at multiple process stages. Real-time WMS updates ensure inventory records reflect actual stock levels continuously, preventing discrepancies that plague manual systems and typically achieving 99.9%+ accuracy.

8.Are automated warehouse solutions scalable for a growing 3PL business?

Scalability represents one of automation’s primary advantages. Modular systems allow incremental expansion—adding robots, storage modules, or conveyor sections as volume grows—without disrupting operations. This approach makes growth less capital-intensive than traditional facility expansion.

9.What are the first steps to implementing automation in our facility?

Begin with an operational audit identifying bottlenecks, error sources, and labour-intensive processes. Quantify current performance metrics to establish improvement baselines. Next, consult automation specialists to explore solutions matching your specific needs, starting with high-impact areas like picking or sortation before expanding to comprehensive facility automation.

10.How does warehouse automation contribute to a safer work environment?

Automation removes workers from dangerous activities including forklift operations, heavy lifting, and repetitive motions causing musculoskeletal disorders. Robots handle these high-risk tasks whilst employees transition to supervisory roles, reducing workplace injuries by 40-60% in facilities implementing comprehensive automation programs.