Picking errors cost Australian warehouses an estimated 1-3% of annual revenue, with mispicks requiring expensive returns processing, customer service intervention, and lost repeat business. For operations processing thousands of orders daily, these losses compound rapidly.

Choosing the right automated order picking system represents one of the most consequential decisions warehouse operators face. Yet selecting the best automated warehouse system isn’t about finding the most advanced technology available—it’s about matching specific operational requirements with appropriate solutions.

This guide provides a practical framework for assessing your needs, understanding available technologies, and making strategic decisions that deliver measurable returns. Whether you’re addressing labour shortages, rising operational costs, or increasing customer expectations for faster fulfilment, the methodology outlined here will help you navigate this critical investment. SmartlogitecX has developed this approach through years of helping Australian operations identify and implement the right automation solutions for their specific challenges.

Assess Your Current Warehouse Operations First

Before evaluating any technology, you need clear visibility into your existing performance. This operational audit establishes the baseline against which you’ll measure automation benefits and calculate realistic ROI projections.

Analyse your order profile and SKU complexity

Your order characteristics determine which automation technologies suit your operation. Consider these factors:

Order volume patterns — Document average daily orders alongside peak demand periods. Seasonal fluctuations of 200-300% require systems that scale efficiently.

Lines per order — Single-item orders suit different picking strategies than multi-line orders requiring consolidation.

SKU diversity — Operations managing 50,000+ SKUs need flexible systems like goods-to-person solutions, whilst lower-SKU environments may benefit from high-density AS/RS.

Evaluate labour costs and picking productivity

Document your current state with specific metrics:

Picks per hour — Manual operations typically achieve 60-80 picks per hour; automated systems can exceed 300.

Labour costs per order — Calculate fully loaded costs including recruitment, training, and turnover expenses.

Staff turnover rates — High turnover (common in warehouse environments) increases training costs and reduces productivity.

Measure accuracy rates and fulfilment speed

Quantify your current picking accuracy and associated error costs. Industry benchmarks suggest manual picking achieves 97-99% accuracy, whilst automated systems routinely exceed 99.9%. Each percentage point improvement eliminates thousands of costly mispicks annually.

Key Types of Automated Warehouse Systems Explained

Understanding the major technology categories helps you identify which solutions align with your operational requirements.

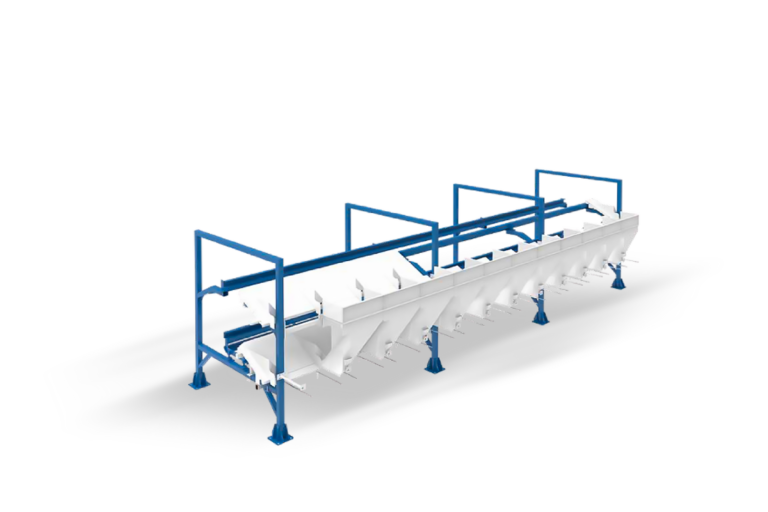

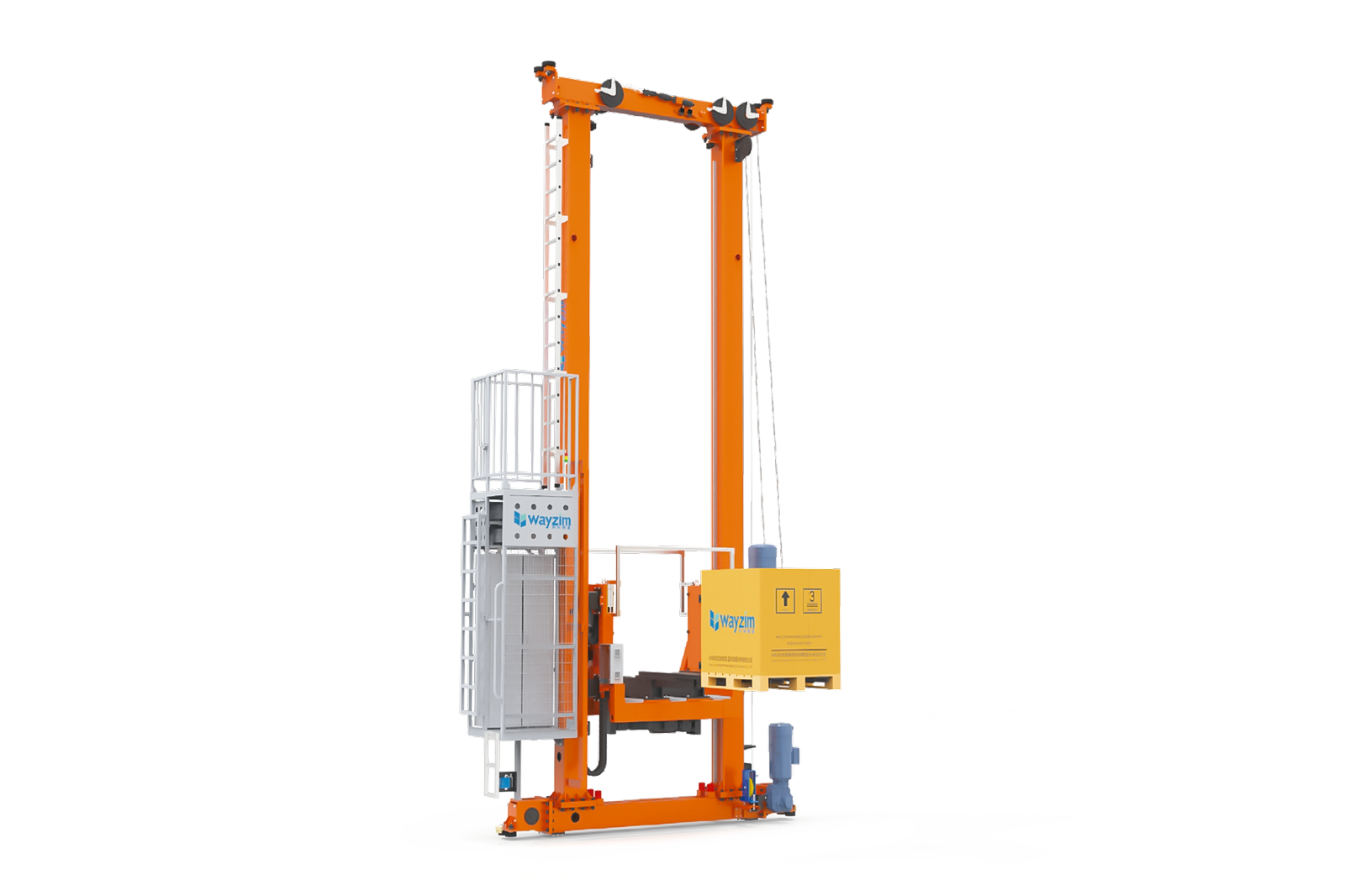

Automated storage and retrieval systems (AS/RS)

SmartlogitecX AS/RS uses cranes, shuttles, or vertical lift modules to store and retrieve inventory within high-density racking structures. These systems maximise vertical space utilisation—critical for Australian warehouses facing rising real estate costs.

Best suited for: High-volume operations with moderate SKU counts, pharmaceutical distribution requiring strict inventory control, and facilities with significant vertical space.

Goods-to-person (GTP) and robotic picking solutions

GTP systems deploy autonomous mobile robots to bring inventory directly to stationary operators, eliminating travel time that consumes 50-60% of manual picking labour. Robotic picking arms handle high-volume sorting tasks with consistent precision.

Best suited for: E-commerce fulfilment with diverse product ranges, operations prioritising rapid scalability, and facilities seeking to reduce worker fatigue and injury.

Autonomous mobile robots (AMRs) versus automated guided vehicles (AGVs)

These technologies serve different operational needs:

Feature AMR’s AGV’s

Navigation Dynamic, sensor-based Fixed paths using markers

Flexibility Adapts to changing layouts Requires infrastructure changes

Initial cost Higher Lower

Best application Variable environments Predictable, repetitive routes

Light-directed and voice-directed picking systems

Pick-to-light and voice-picking represent lower-barrier entry points for automation. These worker-augmentation technologies improve accuracy and speed without replacing manual processes entirely.

Best suited for: Operations seeking incremental improvement, facilities with budget constraints, and environments testing automation readiness.

SmartlogitecX works across this full spectrum of technologies, helping operations identify which combination delivers optimal results for their specific requirements.

Critical Criteria for Selecting Your System

Moving from understanding options to making decisions requires evaluating technologies against your business objectives.

Prioritising order accuracy and throughput gains

Connect technology selection directly to performance improvements. GTP systems typically reduce picking errors by 60-70% compared to manual operations, whilst pick-to-light solutions improve accuracy by 30-40% at lower implementation costs.

Customer satisfaction correlates directly with order accuracy—every mispick risks losing lifetime customer value that far exceeds the cost of the original order.

Planning for scalability and demand fluctuations

Australian e-commerce continues growing at 12-15% annually, meaning your automation investment must accommodate expansion. SmartlogitecX AMR fleets offer particular advantages here—adding robots scales capacity incrementally without infrastructure modifications.

Consider systems that handle peak demand (often 2-3x average volume) without proportional cost increases.

Calculating return on investment realistically

Evaluate ROI across multiple dimensions:

Labour savings — Reduced headcount and overtime requirements

Error reduction — Lower returns processing and customer service costs

Throughput gains — More orders processed within existing space

Space optimisation — Deferred facility expansion through improved density

Automation-as-a-Service (AaaS) models reduce upfront capital requirements, converting large investments into operational expenses that scale with volume.

Ensuring seamless WMS integration

Your automated system must communicate effectively with existing Warehouse Management Systems and ERP platforms. Real-time inventory visibility depends on robust integration—a factor frequently underestimated during vendor evaluation. SmartlogitecX emphasises integration planning early in the selection process, ensuring new technology enhances rather than complicates existing workflows.

A Step-by-Step Implementation Checklist

Follow this practical roadmap when planning your automation project:

1.Complete detailed data analysis

Use operational audit findings to define precise system requirements and performance targets.

2.Evaluate vendors thoroughly

Review case studies from similar operations, request references, and confirm local support availability within Australia.

3.Request system design and simulation

Reputable providers will model expected performance before installation, identifying potential issues early.

4.Plan integration and installation carefully

Phased rollouts minimise disruption to current operations whilst allowing teams to adapt progressively.

5.Invest in team training and change management

Technology succeeds when your workforce understands how to operate alongside it effectively.

Frequently Asked Questions

1.What is the primary purpose of an automated order picking system?

Automated picking systems improve the speed, accuracy, and efficiency of retrieving items from storage to fulfil customer orders, reducing labour costs whilst increasing throughput.

2.What are the main advantages of warehouse automation for e-commerce?

Key benefits include reduced labour dependency, significantly higher order accuracy (99.9%+), faster fulfilment speeds, improved space utilisation, and enhanced worker safety.

3.How do automated systems improve order accuracy?

Automation minimises human error through guided processes (lights, voice commands), barcode verification, and robotic precision, reducing mispicks that cause costly returns.

4.Can warehouse automation address labour shortages?

Yes—automation directly reduces reliance on manual labour for repetitive tasks, allowing existing staff to focus on higher-value roles whilst maintaining throughput during recruitment challenges.

5.How much does an automated warehouse system typically cost?

Costs range from $50,000-$100,000 for pick-to-light systems to several million dollars for comprehensive AS/RS installations. ROI calculations should factor labour savings, error reduction, and throughput improvements.

6.How long does implementation typically take?

Timelines vary from 4-8 weeks for worker-augmentation systems to 12-18 months for large-scale AS/RS projects, depending on complexity and integration requirements.

7.What is the difference between Goods-to-Person and Person-to-Goods picking?

In GTP, robots bring inventory to stationary operators. In Person-to-Goods, workers travel to items. GTP eliminates travel time (50-60% of manual picking labour), dramatically improving efficiency.

Future-Proofing Your Warehouse Investment

Selecting the best automated warehouse system extends beyond solving immediate challenges. AI-driven optimisation, collaborative robots working alongside human operators, and advanced data analytics continue reshaping warehouse capabilities.

The right technology partner helps you build operations that adapt as these capabilities mature. SmartlogitecX specialists work with Australian operations to assess current needs whilst planning for future requirements—ensuring your automation investment delivers returns today and remains relevant as the industry evolves.

Ready to evaluate your warehouse automation opportunities? Contact SmartlogitecX for a tailored assessment of your operation’s potential.