SmartlogitecX Warehouse automation has transformed modern logistics, with facilities reporting efficiency gains exceeding 25% after implementing robotic solutions. The pressure on warehouse operations has never been greater—labour shortages continue to challenge the industry whilst operational costs climb and consumers demand ever-faster delivery times. For logistics and warehouse managers evaluating automation options, understanding the fundamental differences between Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) becomes essential for making the right investment decision. This practical guide examines the AGV versus AMR debate, breaking down the core technologies, operational differences, and specific use cases to help determine which solution aligns with your facility’s unique operational needs and future growth plans.

Understanding the Core Technologies

What is an Automated Guided Vehicle (AGV)?

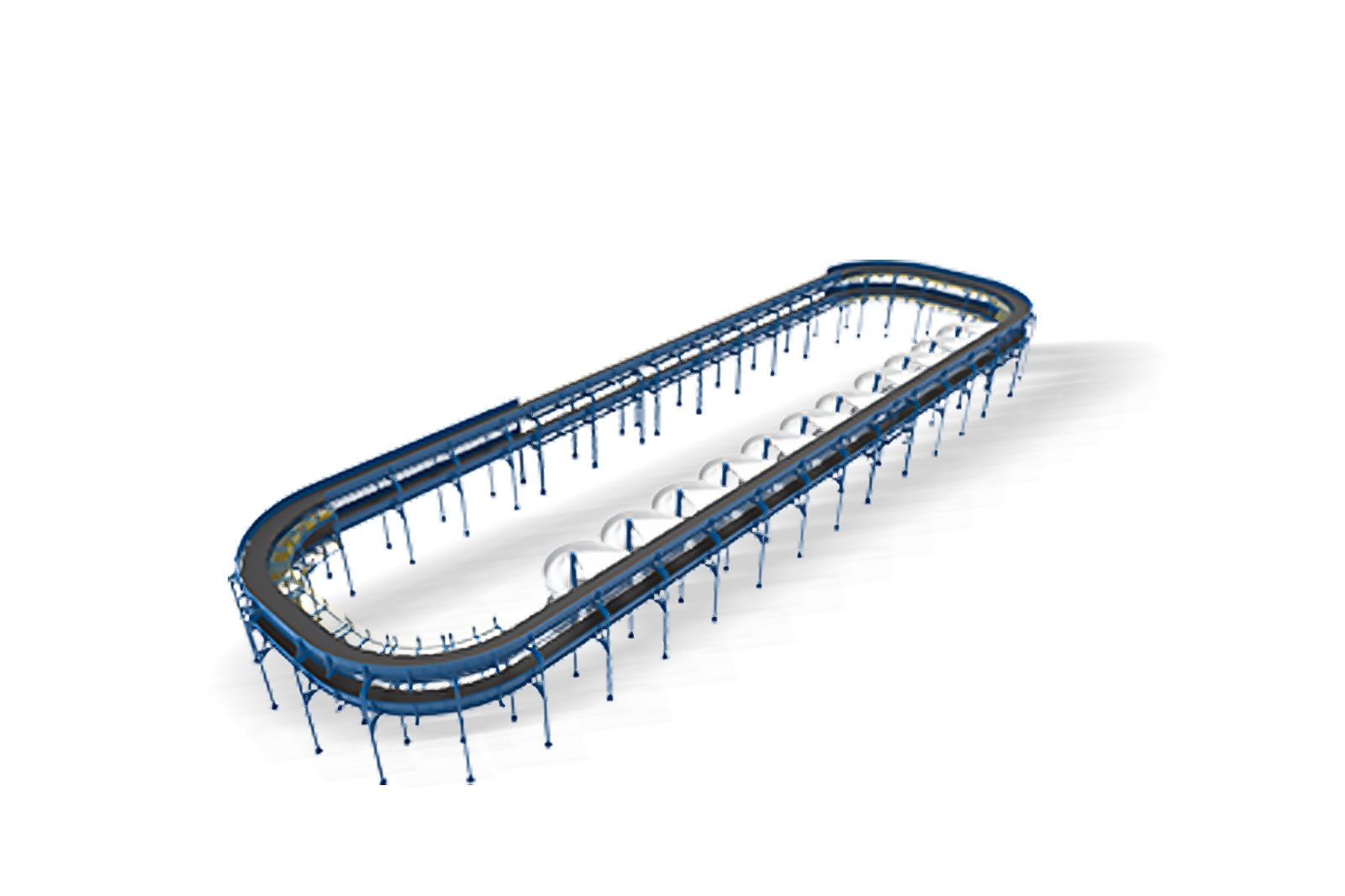

An Automated Guided Vehicle represents a proven approach to warehouse automation, operating as a vehicle that follows predefined paths through your facility using established navigation methods such as magnetic tape, embedded wires, or optical guides installed directly into the warehouse floor. These systems excel at repetitive, point-to-point material transport within structured environments where workflows remain consistent and predictable. The reliability of AGV technology stems from its straightforward operational principle—the vehicle knows exactly where to go because its path has been physically defined, making it an excellent choice for facilities with stable, high-volume material movement requirements that don’t change frequently.

.

What is an Autonomous Mobile Robot (AMR)?

An Autonomous Mobile Robot operates on fundamentally different principles, representing a more advanced approach to warehouse automation that navigates dynamically without requiring any fixed infrastructure modifications to your facility. These sophisticated robots employ an array of sensors, laser-based LiDAR systems, and AI-powered onboard mapping capabilities to understand their surroundings in real-time, continuously calculating and recalculating the most efficient path to their destination. The primary advantage of AMR technology lies in its remarkable flexibility for material transport in dynamic environments, where the robot can safely navigate around unexpected obstacles such as workers, forklifts, or misplaced pallets, ensuring continuous material flow even when the unexpected occurs.

Key Differences: AGV vs AMR – A Detailed Comparison

Navigation and Flexibility

AGVs operate on fixed routes that require physical infrastructure changes whenever path modifications become necessary relaying magnetic tape or rewiring guidance systems can cause significant downtime and incur additional costs, whilst the vehicles themselves cannot navigate around unexpected obstacles and will simply stop and wait until their predetermined path clears. In stark contrast, AMRs utilise sophisticated software algorithms to adapt their routing in real-time, automatically detecting obstacles and calculating alternative paths to maintain material flow, making them exceptionally well-suited for evolving warehouse layouts where flexibility and adaptability are paramount for operational success.

Implementation and Infrastructure

The implementation of AGV systems demands significant upfront investment in guidance infrastructure, with the installation of wires, magnetic strips, or other physical navigation aids potentially disrupting current operations during the setup phase, which can extend over several weeks or even months depending on facility size and complexity. AMRs require minimal physical infrastructure modifications, with implementation primarily involving software-based facility mapping that allows these robots to become operational within weeks rather than months, significantly reducing both the disruption to ongoing operations and the time to achieve return on investment—a crucial consideration for facilities under pressure to improve efficiency quickly.

Scalability and Adaptability

Scaling AGV operations typically involves adding more vehicles to existing fixed paths, which can create traffic congestion issues as vehicle density increases, whilst expanding routes requires additional disruptive infrastructure work that compounds both cost and complexity. AMRs demonstrate superior scalability characteristics, with new robots easily added to the fleet through software configuration alone, and the entire fleet can be quickly reassigned to different tasks or warehouse zones as business needs evolve, offering a genuinely future-proof solution that can adapt to changing market demands without requiring significant infrastructure reinvestment.

Best Use Cases: Which Robot Fits Your Operation?

When to Choose AGVs for Highly Structured Environments

AGVs prove their worth in manufacturing facilities and warehouses characterised by predictable, unchanging processes where consistency and reliability trump flexibility—environments such as automotive manufacturing plants moving heavy components between assembly stations, warehouses transporting pallets from receiving docks to bulk storage locations, or production facilities requiring repetitive work-in-process movements between fixed points. SmartlogitecX frequently recommends AGV solutions for clients with high-volume, consistent routing requirements where the operational patterns have been optimised and are unlikely to change, as these scenarios allow AGVs to deliver exceptional cost-effectiveness and reliability over their operational lifetime.

When AMRs are the Right Choice for Dynamic Logistics

AMRs excel in busy e-commerce fulfilment centres, third-party logistics warehouses, and facilities where processes and layouts undergo frequent modifications to accommodate changing inventory profiles or seasonal demand fluctuations. These robots prove invaluable for goods-to-person picking operations, sorting tasks, inventory replenishment, and navigating collaborative workspaces where human workers and robots must coexist safely and efficiently. The true value of AMR technology emerges in operations requiring agility and rapid adaptation to fluctuating demand patterns, where SmartlogitecX has seen clients achieve remarkable improvements in order fulfilment speed and accuracy whilst maintaining the flexibility to reconfigure operations as market conditions evolve.

Important Factors for Your Investment Decision

Analysing the Total Cost of Ownership

Understanding the complete financial picture requires looking beyond initial purchase prices to consider the total cost of ownership over the system’s operational lifetime. AGVs often present lower per-unit costs initially, but the total investment must account for navigation infrastructure installation, potential operational disruption during setup, and future costs associated with path modifications or system expansions—factors that can significantly impact the true cost over time. AMRs typically command higher per-unit prices but eliminate infrastructure modification expenses, enable faster deployment, and increasingly offer Robotics-as-a-Service (RaaS) models through providers like SmartlogitecX, which can substantially reduce initial capital requirements whilst providing predictable operational expenses that align with business cash flow requirements.

Assessing Your Existing Facility and Workflows

Evaluating your facility’s current state and future trajectory helps determine the most suitable automation approach—facilities with fixed workflows unlikely to change for several years might find AGVs perfectly adequate, whilst growing businesses anticipating layout changes or process evolution will benefit from AMR flexibility. Critical infrastructure considerations include floor quality and levelness, Wi-Fi coverage and reliability for AMR fleet communication, and integration requirements with existing Warehouse Management Systems (WMS) that orchestrate overall facility operations—factors that SmartlogitecX assessment teams evaluate during initial consultations to ensure optimal technology selection.

Making the Right Choice for Your Warehouse Solution

The decision between AGVs and AMRs isn’t about identifying superior technology but rather matching the right solution to specific operational requirements and business objectives. Key considerations for your evaluation should include the predictability of material transport routes, frequency of warehouse layout modifications, whether operational flexibility or minimal initial investment takes priority, and the anticipated speed of operational scaling requirements. Both AGVs and AMRs form part of a comprehensive intelligent warehousing ecosystem that can incorporate automated storage and retrieval systems (AS/RS) to maximise storage density, conveyor systems for high-speed sorting, and sophisticated software platforms that orchestrate these technologies into a cohesive, efficient operation. SmartlogitecX specialists recommend conducting a thorough operational assessment that examines current workflows, future growth projections, and integration requirements to ensure your automation investment delivers maximum value over its operational lifetime.

Frequently Asked Questions

1.What are the main differences between AGV and AMR navigation?

AGVs follow fixed physical paths using guidance systems like magnetic strips or wires embedded in the floor, whilst AMRs use onboard sensors, cameras, and sophisticated mapping software to navigate freely throughout the facility, calculating optimal routes and avoiding obstacles autonomously.

2.Which is safer: AGV or AMR?

Both technologies incorporate comprehensive safety features including emergency stops and obstacle detection, though AMRs generally offer more advanced safety capabilities through their ability to dynamically route around unexpected obstacles, whereas AGVs will stop and wait for obstructions to clear from their predetermined path.

3.Is an AMR more expensive than an AGV?

Initial per-robot costs for AMRs typically exceed AGV prices, but total ownership costs often favor AMRs when factoring in infrastructure installation, operational disruption, and future modification expenses associated with AGV systems. How long does it take to install an AGV or AMR system? AMR systems can achieve operational status within weeks since they require no infrastructure modifications, whilst AGV installations may extend over several months due to the need for physical guidance system installation and testing.

4.Can I use both AGVs and AMRs in the same warehouse?

Hybrid approaches work excellently, with AGVs handling repetitive, high-volume tasks on established routes whilst AMRs manage dynamic operations like order picking and inventory replenishment in other facility zones.

5.Which solution is better for a growing e-commerce business?

AMRs typically suit e-commerce operations better due to their flexibility, rapid scalability, and ability to adapt quickly to fluctuating order volumes and changing inventory profiles common in online retail.

6.What kind of maintenance do these robots require?

Both technologies require regular maintenance including battery care, sensor cleaning, and mechanical component inspection, with AMRs additionally benefiting from periodic software updates that enhance navigation algorithms and operational efficiency.

7.How do these robots integrate with a Warehouse Management System?

Modern AGV and AMR systems are designed for seamless WMS integration, receiving task assignments for transport, picking, or put away operations whilst providing real-time status updates that enable optimal warehouse flow orchestration.

8.What happens if an AMR’s path is blocked?

AMRs automatically detect blockages using their sensor arrays and immediately calculate alternative routes to reach their destination without human intervention, ensuring continuous operational flow.

9.Do I need perfect Wi-Fi coverage throughout my facility for AMRs?

Strong, consistent Wi-Fi coverage proves essential for AMR fleet communication and real-time task management, with site surveys forming a standard component of implementation planning to identify and address coverage gaps.