The Evolution of Conveyor Systems in Modern Industry

In the fast-paced world of industrial operations, efficiency and productivity are not just goals; they are imperatives. As the backbone of warehousing and manufacturing, conveyor systems have evolved from manual to automated solutions, offering unparalleled efficiency and innovation. This comprehensive exploration delves into the transformative role of automated conveyor systems in modern industry, their diverse types, the technology that powers them, and their impact on business operations.

The Advent of Automated Conveyor Systems

Automated conveyor systems represent a significant leap in material handling technology. Unlike their manual predecessors, these systems use advanced artificial intelligence, sensors, and programmable logic controllers to independently route, sort, and manage packages and materials. This automation translates into a myriad of benefits for businesses, including:

- Increased Efficiency and Productivity: By streamlining operations, automated conveyor systems reduce lead times and bolster productivity, directly impacting customer satisfaction.

- Cost Reduction: A key advantage is the significant reduction in labor and energy costs, as these systems eliminate the need for extensive manual labor.

- Accuracy and Quality Improvement: The precision of automated systems minimises errors in handling, thereby enhancing the overall quality of the product movement.

- Enhanced Safety: Safety in the workplace is heightened as these systems minimise the risk of accidents and repetitive stress injuries associated with manual operations.

Varieties of Automated Conveyor Systems

Automated conveyor systems come in various forms, each tailored to specific industrial needs.

- Belt Conveyors: Commonly used for moving items in a linear direction, these are versatile for various products.

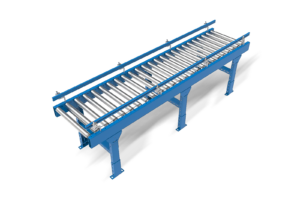

- Roller Conveyors: Ideal for moving bulky or heavy items, using rollers for efficient material handling.

- Chain Conveyors: Best suited for vertical movement and are often employed in multi-story manufacturing or storage facilities.

- Overhead Conveyors: These systems optimise space by transporting goods overhead, improving overall efficiency.

- Pneumatic Conveyors: Used for moving granular or powdery materials, these employ compressed air for transport.

- Sortation Conveyors: Integral in e-commerce and retail, they sort products based on size, weight, or destination.

Customisation: Meeting Specific Business Needs

One of the strengths of automated conveyor systems lies in their adaptability. Businesses can customise these systems based on their specific operational requirements.

- Design and Configuration: Systems can be configured to fit unique facility layouts, handle complex tasks, and navigate through tight spaces.

- Speed and Capacity Adjustments: To match production levels and output requirements, systems can be designed for high-volume production or adjusted for delicate handling.

- Material and Construction Variations: Depending on the nature of the products being handled, systems can be constructed from various materials like stainless steel, aluminum, or plastic.

The Technological Backbone of Automation

The efficiency of automated conveyor systems is driven by:

- Artificial Intelligence: AI enables these systems to make intelligent routing decisions and adapt operations over time.

- Sensors: A range of sensors, including optical and pressure sensors, feed real-time data for efficient tracking and handling.

- Actuators: These components, like servo motors, respond to PLC commands to maneuver conveyor belts and diverters.

Safety and Flexibility: Key Advantages

Automated conveyor systems prioritise safety with features like obstruction sensors and self-diagnostic capabilities for preventive maintenance. Their flexible design allows for easy reconfiguration, adapting to changing operational needs.

The Future and Applications of Automated Conveyor Systems

As technology evolves, so do the capabilities of automated conveyor systems. Industries ranging from manufacturing and warehousing to retail and postal services stand to benefit from these advancements. The future points towards even more sophisticated systems, offering higher efficiency, real-time tracking, and flexible scalability.

Automated conveyor systems are not just a component of modern industry; they are a transformative force, reshaping how materials and products are handled in various sectors. By embracing these automated solutions, businesses can achieve unprecedented levels of efficiency, safety, and adaptability, positioning themselves competitively in an ever-evolving industrial landscape. As we look to the future, continued innovation in this field promises to unlock new potential in operational efficiency and business growth.

Discover the future of Warehouse Automation with SmartlogitecX, brought to you by the technological prowess of WayZim Technologies. We’re leading a logistics revolution in Australia and New Zealand. Choose SmartlogitecX for a blend of local insight and global innovation. Transform your warehouse operations with our specialised technology. Interested in advancing your logistics? Contact our SmartlogitecX sales team for a solution tailored to your needs