Australian e-commerce has grown by over 60% since 2020, placing unprecedented pressure on fulfilment centres to deliver faster and more accurately. Yet many warehouse operators face a difficult reality: rising labour costs, persistent workforce shortages, and error rates that erode margins and damage customer relationships.

SmartlogitecX automated sortation systems offer a proven solution to these challenges. By replacing manual sorting processes with intelligent, high-speed technology, these systems enable warehouses to process thousands of items per hour with exceptional accuracy.

This guide explores how sortation systems function, the different types available, their core benefits for e-commerce fulfilment, and essential considerations when selecting the right solution for your operations. SmartlogitecX has developed this resource to help Australian warehouse operators make informed automation decisions.

What Are Automated Sortation Systems and How Do They Work?

At their core, automated sortation systems identify items entering a facility and divert them to specific destinations—whether that’s a packing station, shipping lane, or storage location. This happens without manual intervention, enabling consistent, high-speed processing around the clock.

The Core Process Flow

Every sortation system follows a four-stage process:

In-feed and Induction — Items enter the system either manually or via SmartlogitecX automated conveyors. Singulation technology separates items to ensure each piece moves through individually.

Identification — Barcode scanners, RFID readers, or machine vision systems capture item data. This automatic identification determines where each item must travel.

Sorting and Diverting — The system’s logic activates mechanical components—tilting trays, sliding shoes, or belt carriers—to route items to their correct destination.

Out-feed — Items arrive at designated locations ready for the next stage of processing, whether packing, dispatch, or storage.

Integration with Warehouse Management Systems

Sortation hardware alone delivers limited value. The real operational gains come from integration with your Warehouse Management System (WMS) or Warehouse Control System (WCS). This connectivity enables real-time decision-making, accurate inventory tracking, and performance analytics that drive continuous improvement.

Key Types of Automated Sorting Systems for Warehouses

The optimal sorter type depends on your specific operational requirements. Item size, weight, fragility, and required throughput rates all influence which technology best suits your facility.

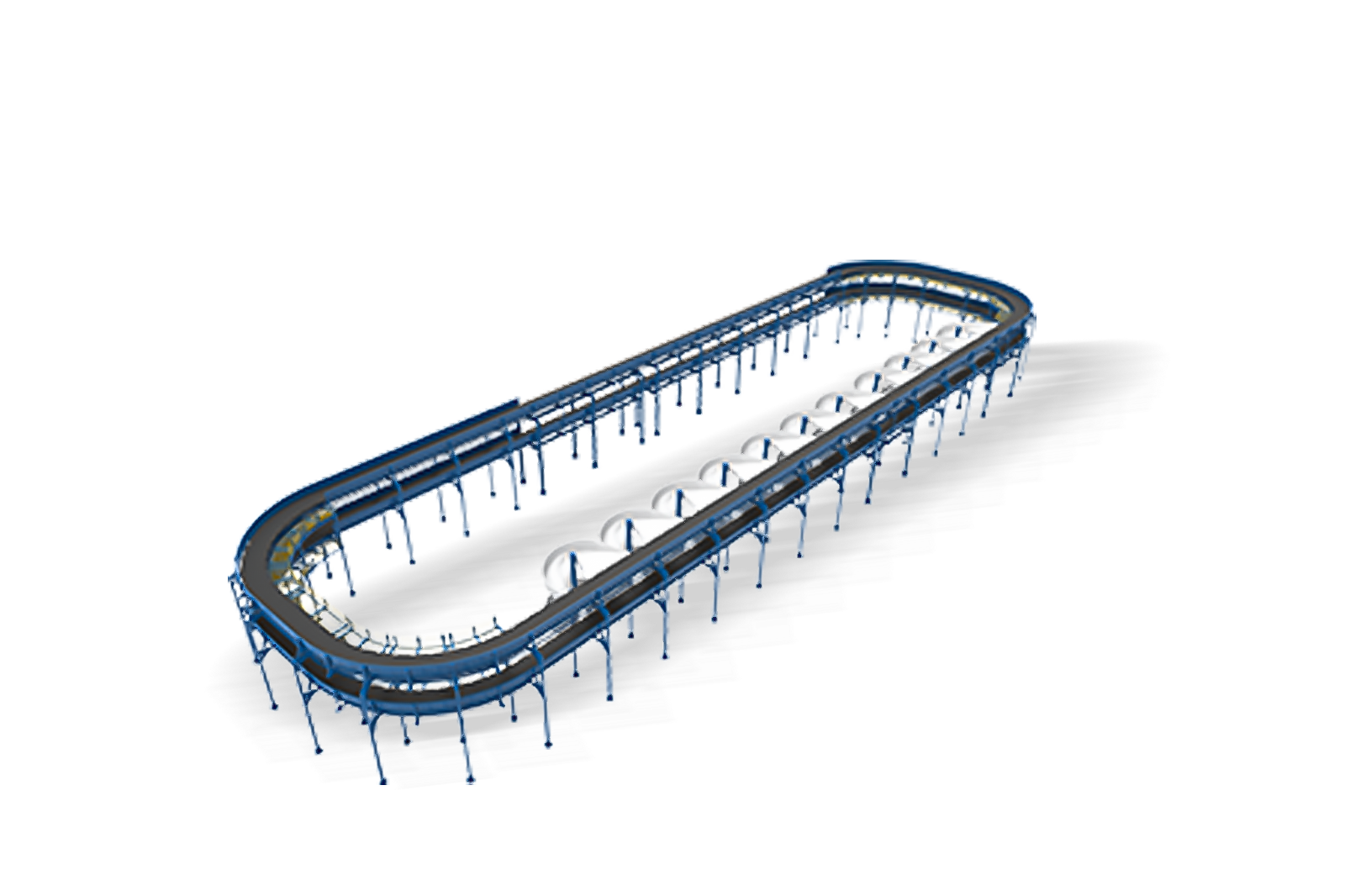

Tilt Tray Sorters

Tilt tray systems transport items on individual carriers that tilt at the appropriate moment, gently sliding products into destination chutes. This gentle handling makes them ideal for fragile goods, apparel, and parcels requiring careful treatment.

These systems offer high-speed operation while maintaining accuracy rates exceeding 99.9%. They handle a wide variety of item types, making them versatile choices for e-commerce fulfilment centres with diverse product ranges.

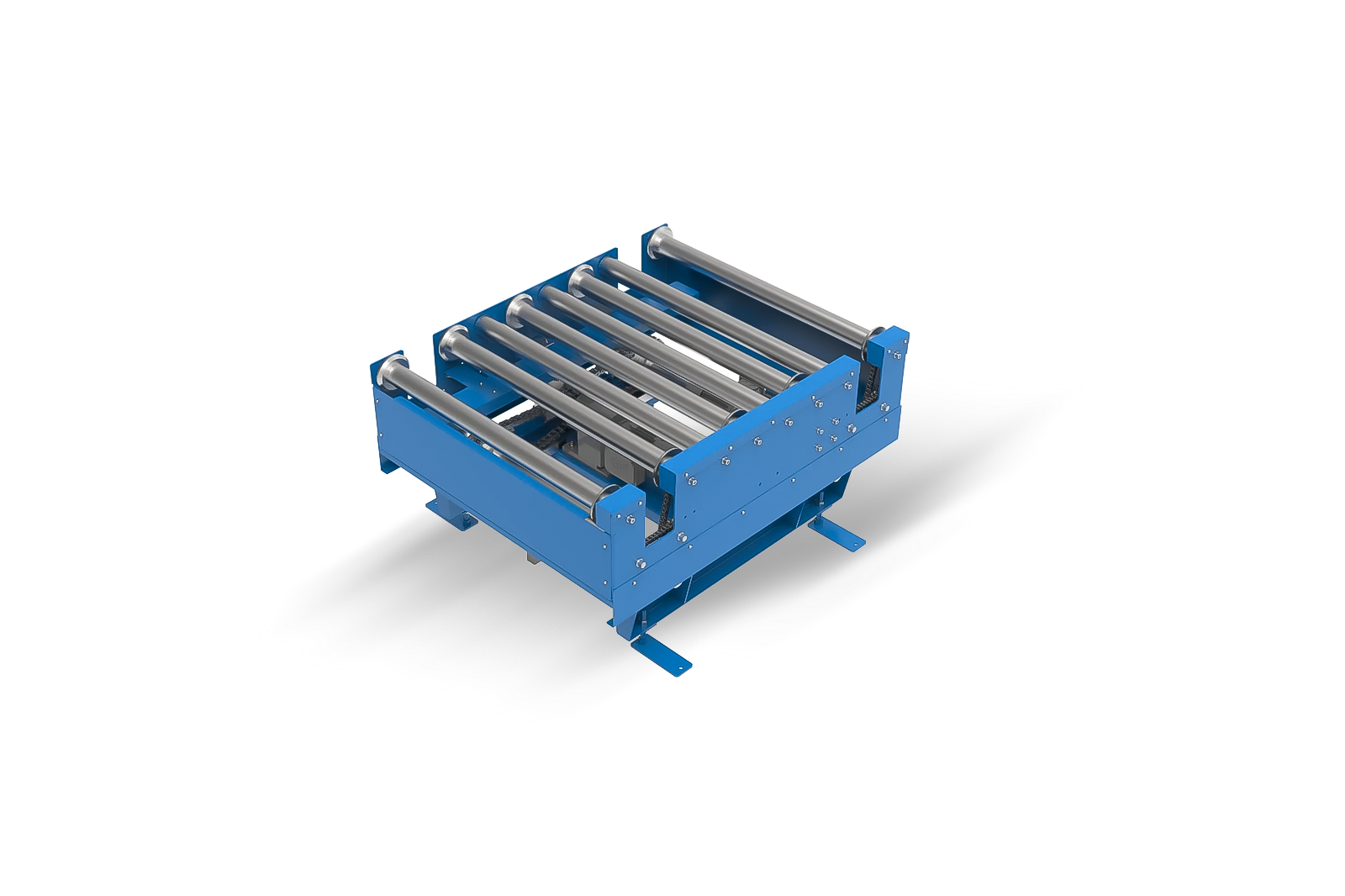

Cross Belt Sorters

Cross belt technology uses small conveyor sections mounted on individual carriers travelling along a track. Each carrier’s belt activates independently to discharge items laterally into destination lanes.

This design excels at high-speed, high-accuracy sorting of small to medium-sized parcels. Cross belt systems are particularly well-suited to e-commerce operations processing high volumes of varied package sizes.

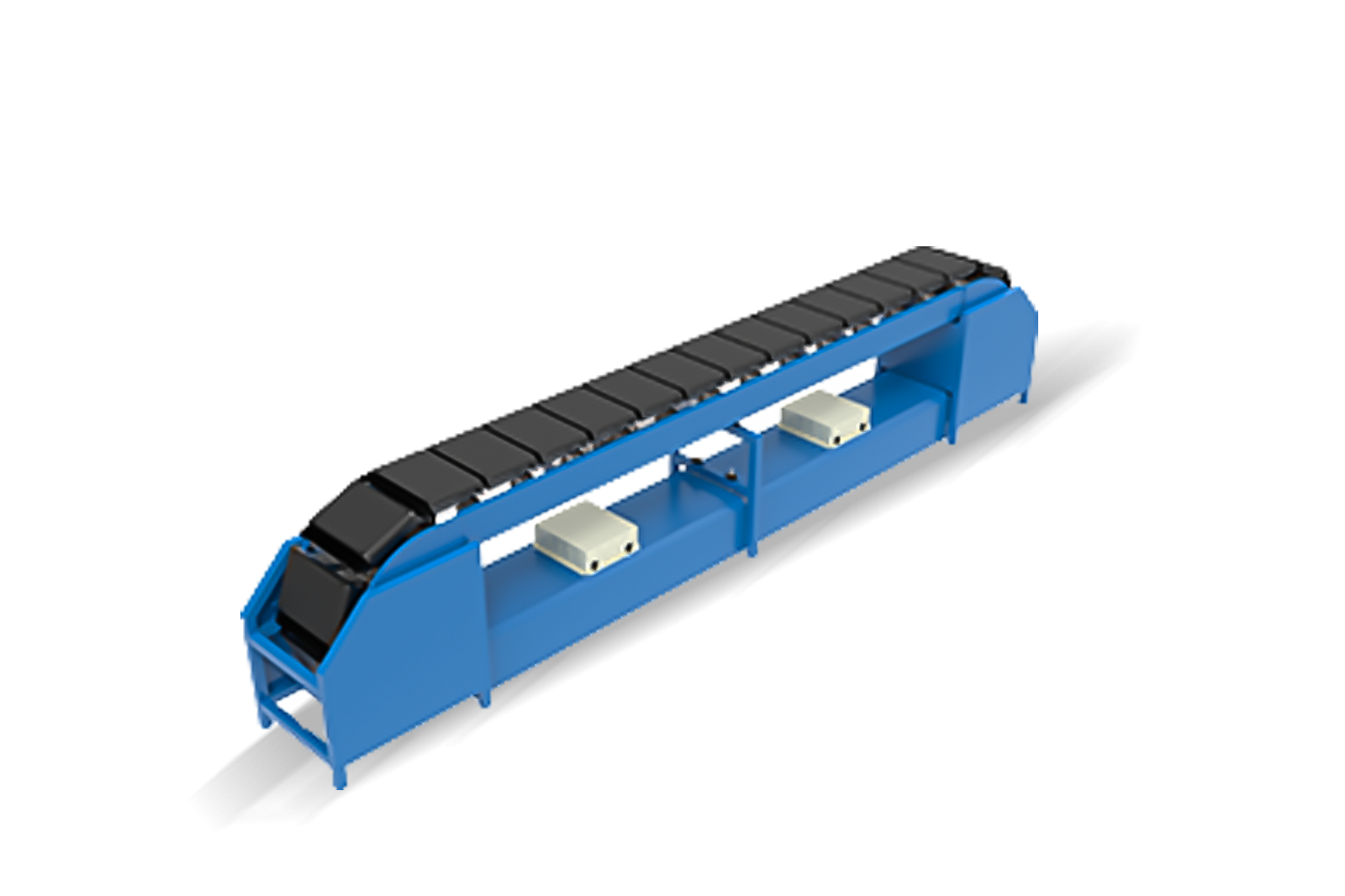

Sliding Shoe Sorters

Sliding shoe systems use rows of diverter “shoes” that slide across a flat conveyor surface, pushing items into outbound lanes. Known for their robust construction and reliability, these systems handle high-volume case and tote sorting effectively.

They work best with relatively uniform item shapes and sizes, making them popular choices for operations handling standardised packaging.

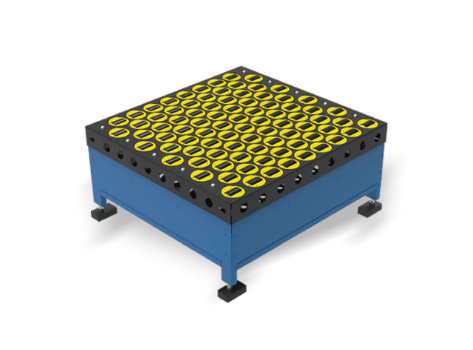

Robotic Sortation Systems

Autonomous Mobile Robots (AMRs) represent the newest evolution in sortation technology. These systems transport items to sorting destinations or use robotic arms to pick and place products with precision.

SmartlogitecX recommends robotic solutions for operations requiring exceptional flexibility. Their modular nature allows rapid scaling for seasonal peaks or business growth, and they adapt readily to changing product mixes.

The Core Benefits of Automation in Order Fulfilment

Investing in sortation automation delivers measurable improvements across multiple operational dimensions.

Speed, Accuracy, and Cost Reduction

Increased throughput — Automated systems process 2,000 to 20,000+ items per hour depending on configuration, far exceeding manual sorting capabilities. This speed is essential for meeting next-day delivery expectations.

Enhanced accuracy — Automation eliminates the inconsistency inherent in manual processes. Error rates typically drop below 0.1%, reducing mis-shipments, lowering return handling costs, and improving customer satisfaction scores.

Lower operational costs — While initial investment is significant, long-term ROI comes through reduced labour dependency, minimised error-related expenses, and more efficient allocation of staff to value-adding tasks. Many operations achieve full payback within 2-3 years.

Workplace Safety and Scalability

Improved safety — Automating repetitive, physically demanding sorting tasks significantly reduces workplace injury risks. For Australian operations, this supports WHS compliance while reducing workers’ compensation costs and lost productivity.

Scalability — Modular system designs accommodate demand fluctuations without proportional labour increases. SmartlogitecX designs solutions that address current requirements while allowing for future capacity expansion as your business grows.

Important Factors When Choosing a Sortation System

Successful automation requires careful evaluation of your operational context.

Product Characteristics and Throughput Requirements

Analyze your item mix thoroughly. Document the full range of sizes, weights, shapes, and fragility levels you handle. Systems optimised for small parcels may struggle with oversized items, while gentle-handling sorters might be unnecessary for robust products.

Calculate current and projected throughput needs in items per hour and per day. Factor in peak season demands—which may be 3-5 times higher than baseline volumes—when sizing your system.

Space, Integration, and ROI Considerations

Physical space constraints determine whether linear, vertical, or compact modular configurations suit your facility. Modern systems offer surprising flexibility, but accurate facility measurements are essential for proper planning.

Integration matters — Seamless WMS/WCS connectivity ensures accurate data flow between systems. SmartlogitecX emphasises this integration as critical to operational success; poorly connected systems create data silos that undermine efficiency gains.

Evaluate total ROI — Look beyond initial capital costs. Calculate long-term returns based on labour savings, accuracy improvements, increased processing capacity, and reduced error-related expenses over a 5-7 year horizon.

Future Trends Shaping Warehouse Automation

AI, Robotics, and Sustainability

Artificial intelligence is making sortation systems increasingly intelligent. Machine learning algorithms optimise routing decisions in real-time, predict maintenance requirements before failures occur, and handle complex sorting logic with minimal human intervention.

Collaborative robotics continues advancing, with cobots working alongside human operators to combine automation efficiency with human flexibility and problem-solving capabilities.

Sustainability has become a priority. Modern systems emphasise energy efficiency and contribute to reduced carbon footprints through optimised operations and minimised waste.

Data analytics generated by sortation systems enables continuous improvement, helping operations identify bottlenecks and optimise performance over time.

Streamlining Your Fulfilment Operations

Manual sorting processes are no longer sustainable for e-commerce businesses pursuing growth in competitive Australian markets. Order volumes continue rising while customer expectations for speed and accuracy intensify.

Automated sortation systems represent a strategic investment in operational efficiency, order accuracy, and customer satisfaction. Adopting this technology positions your business for future success and the scalability needed to capture market opportunities.

Contact SmartlogitecX to discuss how sortation automation can transform your warehouse operations.

Frequently Asked Questions

1.What is the main function of an automated sorting system?

Automated sorting systems identify items and divert them to specific locations for order fulfilment or shipping, dramatically improving speed and accuracy compared to manual methods.

2.How much space is required for an automated sorting system?

Space requirements vary based on system type and throughput needs. Compact, modular, and vertical configurations exist for facilities with limited floor space.

3.Can automated sorting handle fragile items safely?

Yes. Tilt tray and pouch sorters are specifically designed for gentle handling of fragile or delicate products without damage.

4.What is the typical ROI timeline for sortation automation?

Most operations achieve full return on investment within 2-3 years through labour savings, improved accuracy, and increased processing capacity.

5.How do automated systems integrate with existing WMS platforms?

Integration occurs through a Warehouse Control System (WCS), which bridges the WMS and physical sorter, enabling real-time data exchange and coordinated operations.