In response to the implementation of the country’s Guiding Opinions on Accelerating the Intelligent Development of Coal Mines[1], a coal mine in Inner Mongolia joins hands with Wayzim to build an intelligent SmartlogitecX Automated Storage and Retrieval System (AS/RS) featuring automated, IT-based, and energy-efficient operations. This project complies with the requirements for the “construction of intelligent parks and operation management systems” and improves the efficiency, safety, and digital management level of material operations.

Aiming to help coal mines improve their material management efficiency, Wayzim has developed three types of AS/RS for warehousing coal mine materials with different weights and operation requirements.

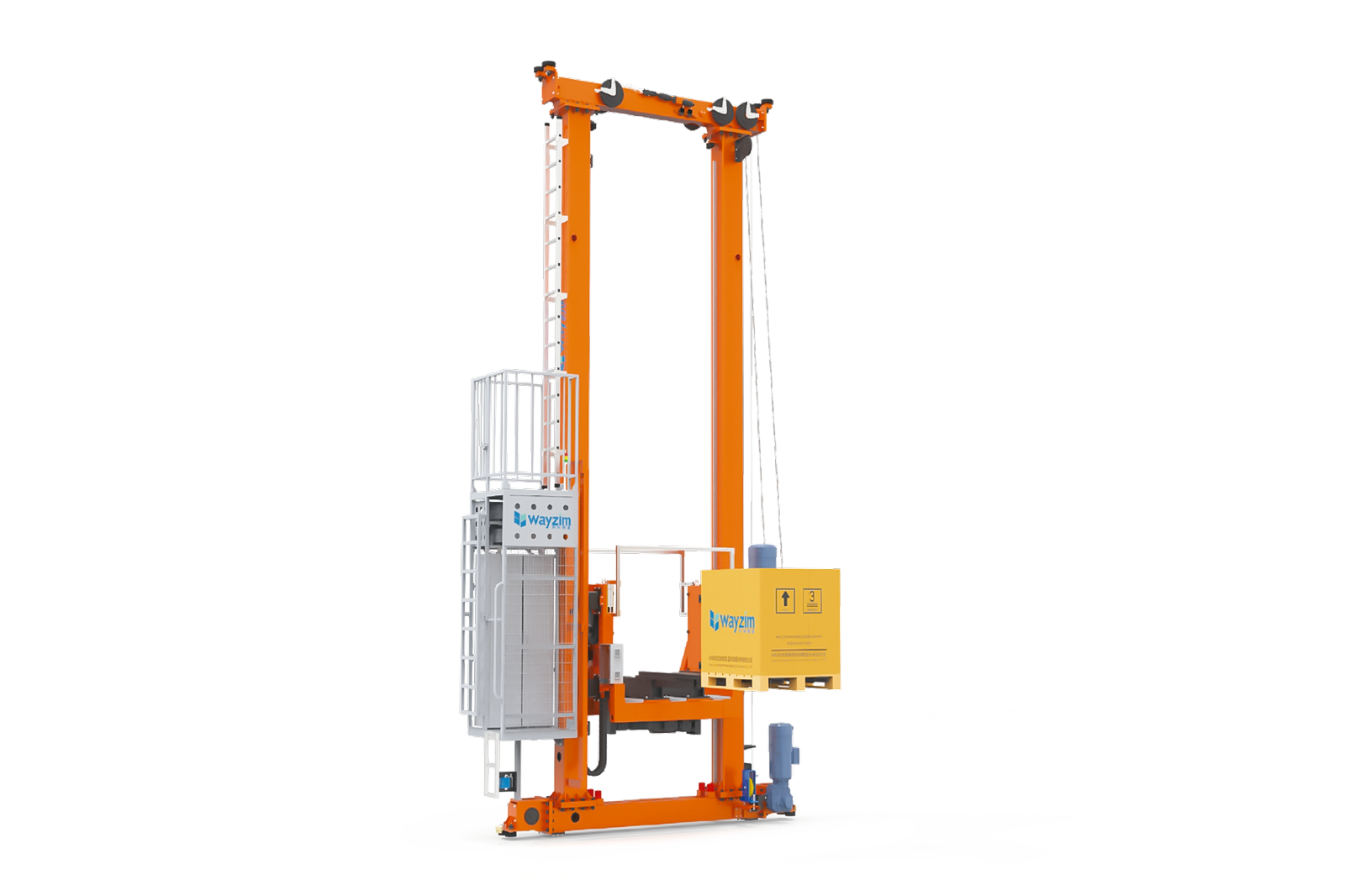

Using stacker cranes as the core equipment, the AS/RS enables automated, visualised, and intelligent management of the warehousing process from inbound to outbound with the support of the SmartlogitecX Warehouse Management System (WMS), the Warehouse Control System (WCS), and the Digital Twin System (3DMS). It defines a replicable and extensible modern warehousing standard system for the coal mining industry.

Manual material collection lowers the outbound and count efficiency, requires massive manual work, and poses safety risks.

Manual material verification leads to a high error rate of inventory data and stock locations. Floor stacking and traditional shelf storage lower space utilisation and restrict the storage height.

Floor stacking and traditional shelf storage lower space utilisation and restrict the storage height.

The zoned design provides customised stacker crane systems for materials of different weights and combines machine vision with an intelligent software control platform to provide a comprehensive intelligent warehousing solution that allows for efficient coordination between hardware and software.

The innovative application of the grayscale algorithm vision system delivers a tote detection accuracy of up to 99.99%.

The tote frame capacity is calculated and sent to the WMS in real time, increasing the space utilisation by 35%.

Adaptive clamping devices are equipped to handle pallets of different sizes.

The software system intelligently allocates stock locations, enabling automated consolidation of materials of the same type and reducing the shuttling time.

High-load (2,000 kg/pallet) stacker cranes and double-reach shelves are used in this zone, increasing the storage density by 50%.

Laser ranging and anti-sway technologies are used to ensure stable, efficient storage and retrieval of heavy materials.

Intelligent Warehousing Advances in Depth and Breadth, Bringing Opportunities of Agile Operations for Traditional Coal Mines

As a foundational energy source in China, coal mines are taking on the strategic shift of their focus from production safety to smart operations during the high-quality development phase.

Wayzim will persistently focus on the development of intelligent logistics and warehousing equipment and provide industry solutions for coal mines to accomplish digital and intelligent transformation from IT-based warehousing to intelligent operations and from isolated platforms to a collaborative ecosystem.