Chutes, those familiar sloped tunnels, play a surprisingly vital role in modern logistics and material handling. Their simple yet effective design helps move goods efficiently and safely, making them a versatile tool across various industries.

What is a Chute?

A chute is a narrow, inclined passage designed to guide the flow of objects through gravity. It can be constructed from various materials, including metal, plastic, or concrete, and can be straight, curved, or even spiral in shape.

Benefits of Chutes

- Increased efficiency: Chutes significantly improve the speed and ease of moving goods compared to manual carrying or conveyor systems.

- Reduced labor costs: Automation of material handling through chutes minimises the need for manual labor, lowering operational expenses.

- Improved space utilisation: Chutes can be installed in tight spaces or overhead, maximising floor space utilisation.

- Enhanced safety: Chutes eliminate the risk of injuries associated with manual lifting and carrying of heavy objects.

- Reduced product damage: Smooth surfaces and controlled flow minimise the risk of damage to delicate items during transportation.

- Wide variety of applications: Chutes can handle various materials, from bulk goods and parcels to small parts and liquids.

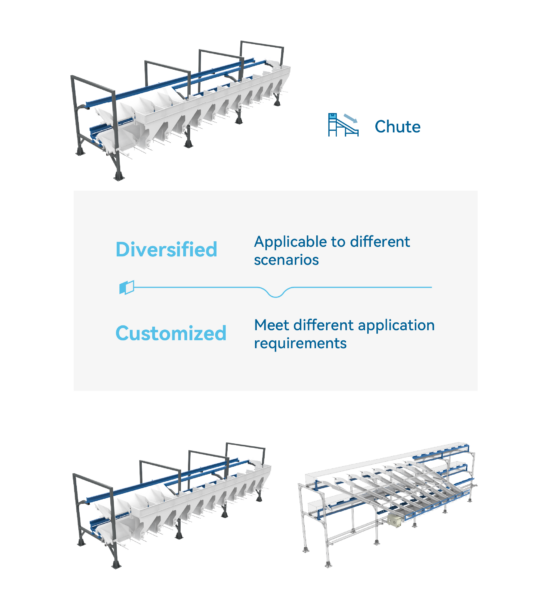

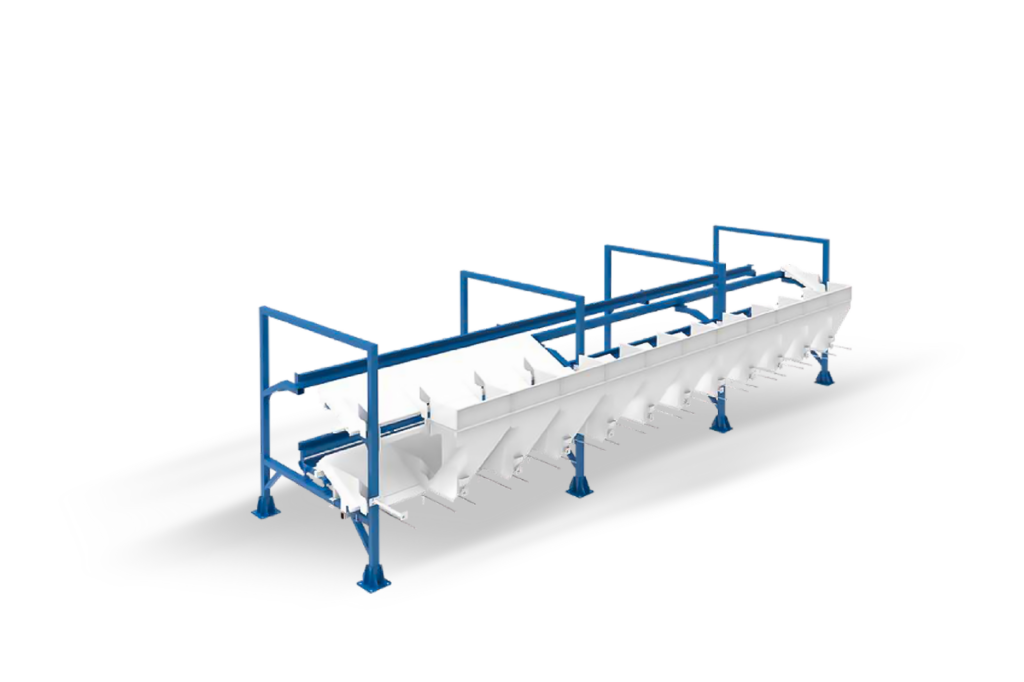

Types of Chutes

The specific type of chute used depends on the intended application and material being handled.

- Gravity chutes: Utilise gravity alone to move objects down the incline.

- Spiral chutes: Offer a compact design for transporting goods vertically.

- Telescoping chutes: Allow for adjustable length and height to accommodate different needs.

- Sorting chutes: Incorporate diverters to separate objects based on size, shape, or other characteristics.

- Pneumatic chutes: Use air pressure to propel objects through the chute, ideal for lightweight materials.

Applications of Chutes

Chutes are used in various industries for diverse purposes, including,

- Warehouses: Chutes facilitate the movement of packages, boxes, and other goods within the warehouse.

- Manufacturing plants: Used to transport raw materials, components, and finished products between production stages.

- Retail stores: Chutes can be used for transporting goods from stockrooms to sales floors or for returning items to the cashier.

- Waste management: Used to collect and move garbage, recycling, and other waste materials.

- Construction: Used to transport materials like concrete, gravel, and debris during construction projects.

- Amusement parks: Chutes are a key component of roller coasters and other attractions.

Future of Chutes

Technological advancements are continuously improving the effectiveness and functionality of chutes.

- Smart chute systems: Sensor-equipped chutes can track and manage inventory levels, optimise material flow, and improve safety.

- Robotic integration: Combining chutes with robots can automate loading, unloading, and sorting processes for increased efficiency.

- Material-specific design: Chutes can be customised with specialised materials and coatings to handle specific types of goods with optimal performance.

These advancements will ensure that chutes remain a vital and versatile tool in logistics and material handling, facilitating efficient, safe, and cost-effective movement of goods across various industries.

Discover the future of Warehouse Automation with SmartlogitecX, brought to you by the technological prowess of WayZim Technologies. We’re leading a logistics revolution in Australia and New Zealand. Choose SmartlogitecX for a blend of local insight and global innovation. Transform your warehouse operations with our specialised technology. Interested in advancing your logistics? Contact our SmartlogitecX sales team for a solution tailored to your needs.