In fast-paced logistics environments, optimising the flow of packages and products is essential for streamlined fulfilment, happy customers, and a solid bottom line. Cross-belt sorters deliver exceptional versatility and unmatched throughput, establishing themselves as the cornerstone of modern warehouse automation. Let’s explore what makes these systems so adaptable and examine the crucial applications where they excel.

The Ingenuity of Cross-Belt Sorters

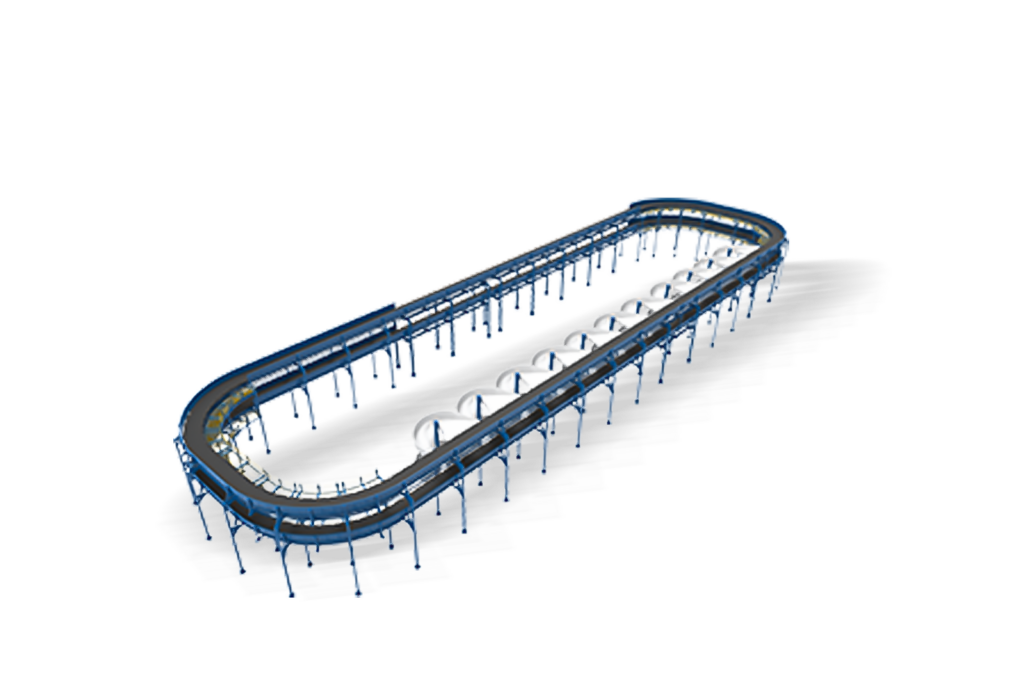

These sophisticated sorting mechanisms consist of individually controlled carts travelling along a primary conveyor line. Each cart features its own miniature conveyor belt running perpendicular to the main track. These mini-belts activate on command, quickly diverting packages toward their designated sortation routes. Their design makes them exceptionally adaptable to parcels and containers of varying shapes and sizes.

Unlocking Warehouse Efficiency: Applications of Cross-Belt Sorters

The adaptability of cross-belt sorters lends them to various logistics challenges and situations:

- E-Commerce Order Fulfilment: Online retail demands speed, and cross-belt sorters deliver. They swiftly process large volumes of mixed-size packages, streamlining order processing and guaranteeing rapid shipment dispatch.

- Parcel and Postal Operations: Postal hubs and logistics providers handle an incredibly diverse range of parcels. Cross-belt sorters effortlessly navigate this spectrum, seamlessly sorting various packages and envelopes by destination.

- Manufacturing Distribution: From assembly lines to product packing, cross-belt sorters efficiently route different-sized containers or materials throughout a manufacturing facility, maintaining production flow.

- Reverse Logistics: Returned items often come in unique sizes or packaging materials. Cross-belt sorters can adapt to these challenges, directing goods to the appropriate destinations and increasing the efficiency of return processes.

RELATED: Cross Belt Sorters: Orchestrating Efficient Order Fulfillment

Features: Unpacking the Advantages of Cross-Belt Sorters

The adaptability of cross-belt sorters is bolstered by a combination of valuable characteristics:

- Scalability: Cross-belt sorter systems are remarkably modular. As your operational growth demands greater throughput, additional carts and divert zones can be seamlessly integrated, maintaining future-proof operations.

- Throughput: These sorters handle impressive volumes with high accuracy, even while juggling packages of mixed sizes. The result is expedited order processing and boosted capacity.

- Gentle Handling: Even fragile or oddly shaped items flow smoothly through a cross-belt sorter. This makes them ideal for applications where minimising product damage is a crucial concern.

- Reliability: Designed to handle the relentless demands of high-volume warehouses, cross-belt sorters prioritise uptime and ensure continuous production.

- Integration: Working in synergy with modern warehouse management systems (WMS), cross-belt sorters can automatically adjust and optimise sorting operations based on live data.

The Cost-Benefit Equation: Weighing Your Investment

While the benefits are impressive, evaluating the initial investment alongside potential returns is critical in deciding whether a cross-belt sorter is right for you. Let’s review some key factors:

- Increased Order Fulfilment Accuracy: Reduced picking errors and streamlined dispatch translate to cost savings and higher customer satisfaction.

- Reduced Labour Costs: Automation eases reliance on manual sorting processes, freeing your workforce for more value-added tasks.

- Improved Sorting Speed: Rapid processing time means orders get to customers faster, boosting loyalty and brand perception.

- Increased Capacity: Efficient throughput allows you to manage higher volumes without proportionate increases in personnel or real estate investment.

- Operational Flexibility: Cross-belt sorters can handle future changes in product lines or order profiles due to their adaptability.

Is a cross-belt sorter the right fit?

If you find yourself answering positively to any of these, you’d likely benefit from a cross-belt sorter:

- Does your warehouse struggle with a surge of mixed-size packages?

- Are order fulfilment errors hurting your bottom line and customer satisfaction?

- Could reduced labour reliance benefit your operations?

- Do you need to increase throughput without costly renovations or new warehouse construction?

FAQs: Cross-Belt Sorters

Q: Are cross-belt sorters suitable for small-scale facilities?

A: They offer outstanding scalability. Cross-beam systems can begin with a modest footprint and modularly expand in tandem with your growth.

Q: Will a cross-belt sorter effectively handle our mix of products?

Cross-belt sorters boast impressive versatility for irregular items, flat items, and a wide range of standard shipping containers.

Q: What are the maintenance and upkeep requirements?

A: Reputable manufacturers design cross-belt sorters for low-maintenance operation, ensuring maximum uptime with minimal disruptions.

Q: Does integrating a cross-belt sorter require a lengthy disruption?

A: Experienced system integrators streamline installations to minimise downtime. Phased strategies facilitate a gradual changeover for smoother deployment.

RELATED: How Cross Belt Sorters Streamline Package Handling?

Join forces with SmartlogitecX, backed by the technological strength of WayZim Technologies, and lead the charge in Warehouse Automation in Australia and New Zealand. We are more than a service; we are your strategic partner in redefining logistics. Opt for SmartlogitecX to harness the full potential of advanced technology, crafted with an understanding of the local market. Connect with our sales team to begin your journey towards an automated, efficient future.