In the fast-paced world of logistics and e-commerce, efficient handling and processing of goods are crucial for optimal performance. The DWS, also known as the Dynamic Dimensioning, Weighing and Scanning system, emerges as a revolutionary warehouse automation solution, streamlining operations and enhancing accuracy.

What is DWS?

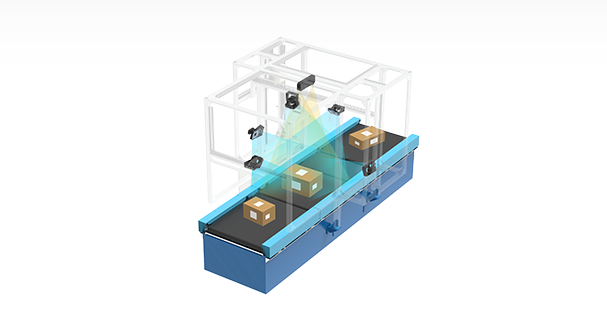

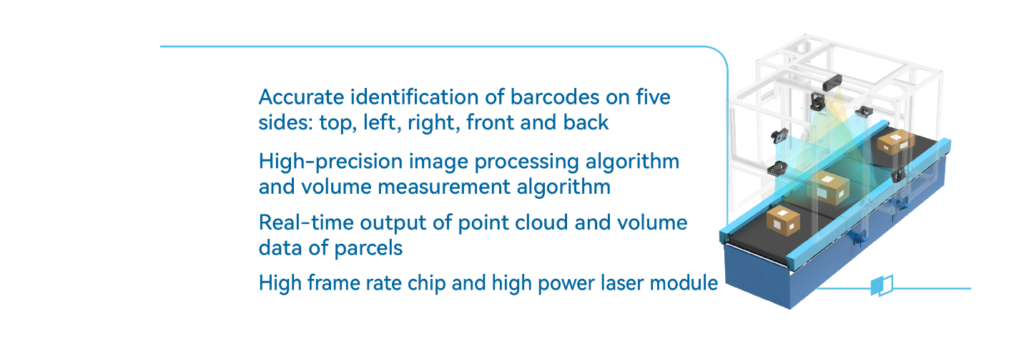

Imagine a single system capable of capturing vital data about every item passing through. DWS achieves this feat by integrating three key functions: Dimensioning, weighing, and scanning.

- Dimensioning: Utilising laser technology to accurately measure the length, width, and height of each item.

- Weighing: Employing high-precision scales to determine the weight of each item.

- Scanning: Reading barcodes or QR codes for identification and tracking purposes.

Benefits of DWS

- Increased efficiency: DWS automatically captures data in real-time, eliminating the need for manual measurement and weighing, significantly increasing processing speed.

- Improved accuracy: Precise measurements and accurate identification minimise errors and ensure data integrity throughout the supply chain.

- Enhanced space utilisation: Accurate dimensioning data allows for optimal packing and storage, maximising space utilisation within warehouses and distribution centres.

- Reduced shipping costs: Accurate weight data ensures proper shipping charges and optimises transportation costs.

- Improved inventory control: Real-time data on item dimensions and weight facilitates precise inventory management and forecasting.

- Automated reporting: DWS systems can automatically generate reports on various aspects of inventory and shipment data, providing valuable insights for business optimisation.

Applications of DWS

- E-commerce fulfillment centres: Accurately measuring and weighing a high volume of diverse items for efficient packing and shipping.

- Parcel sorting facilities: Optimising sorting and routing based on accurate weight and dimension data.

- Retail distribution centres: Managing and distributing various products with accurate size and weight information.

- Manufacturing and production lines: Tracking and verifying the dimensions and weight of components and parts.

- Warehouses and distribution centres: Improving inventory control and space utilisation with real-time data.

Types of DWS

- Conveyor-based systems: DWS modules integrated into conveyor lines for automated data capture during item movement.

- Stand-alone systems: Freestanding units for measuring and weighing individual items on demand.

Future of DWS

The future of DWS is driven by continuous advancements in technology.

- Integration with robotics: Combining DWS with robots for automated loading and unloading of items for measurement and scanning.

- AI and machine learning: Optimising data analysis algorithms for improved accuracy and predictive capabilities.

- Internet of Things (IoT) integration: Real-time data sharing and synchronisation across interconnected devices within the supply chain.

These advancements will further enhance the capabilities of DWS, solidifying its position as a vital tool for modern logistics operations, ensuring optimal efficiency, accuracy, and data-driven decision-making across various industries.

Empower your logistics with SmartlogitecX, fueled by WayZim Technologies. As leaders in Warehouse Automation for the Australian market, we’re dedicated to delivering efficiency and innovation right to your doorstep. SmartlogitecX’s approach is two-fold: globally informed, locally applied. Take the first step towards optimised operations by reaching out to our sales team for a solution that speaks directly to your needs.