What is DWS?

DWS stands for Dynamic Dimensioning, Weighing, and Scanning systems. It refers to a technology used in logistics and warehousing to automatically measure the dimensions, weight, and other characteristics of packages as they move along a conveyor belt.

This data is crucial for various applications, including:

Calculating shipping costs: Accurately measured dimensions and weight allow for precise calculation of shipping costs, ensuring both cost efficiency and fair pricing for customers.

Optimising warehouse space: By knowing the exact dimensions of each package, warehouse managers can optimise storage space allocation and ensure efficient use of resources.

Automated sorting and routing: DWS systems can be integrated with sorting systems to automatically route packages to the correct destination based on their size and weight.

Improving packing efficiency: DWS data can be used to determine the optimal box size for each package, minimising wasted space and shipping costs.

Ensuring regulatory compliance: Some regulations, such as those for air freight, require accurate dimensional and weight information. DWS systems can help businesses comply with these regulations and avoid penalties.

Benefits of DWS

Increased accuracy: DWS systems offer a significant improvement in accuracy compared to manual measurement, reducing errors and discrepancies.

Reduced labor costs: DWS automates the entire process of dimensioning, weighing, and scanning, eliminating the need for manual labor and associated costs.

Increased speed and efficiency: DWS systems can process packages quickly and efficiently, improving throughput and reducing bottlenecks in the logistics chain.

Improved data quality: DWS systems provide real-time data that can be used for various analytics and optimisation purposes.

Reduced shipping costs: By optimising packing and calculating accurate shipping costs, DWS can help businesses save money on their shipping expenses.

Components of DWS Systems

Dimensioning systems: These typically use laser or camera technology to measure the length, width, and height of each package.

Weighing systems: These use load cells or other technologies to accurately measure the weight of each package.

Scanning systems: These use barcode or RFID technology to scan the package label and capture additional data such as product information and destination address.

Software: The software integrates the data from all components and provides reports, analytics, and control functions.

Types of DWS Systems

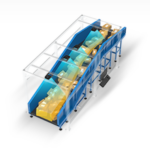

Conveyor-based systems: These are the most common type of DWS system and are used to process packages moving on a conveyor belt.

Fixed-mount systems: These are installed at specific locations in the warehouse and are used to measure packages that are not on a conveyor belt.

Mobile systems: These are portable DWS systems that can be used in various locations within the warehouse.

DWS technology plays a vital role in modern logistics and warehousing operations. By automating the measurement of package dimensions, weight, and other characteristics, DWS systems help businesses improve accuracy, speed, efficiency, and cost-effectiveness. As the demand for faster and more efficient logistics solutions continues to grow, DWS is expected to play an increasingly important role in the future of the industry.

At SmartlogitecX, supported by WayZim Technologies, we prioritise your logistics needs. Pioneering in Warehouse Automation across Australia and New Zealand, we offer solutions that are not only advanced but also attuned to your specific requirements. Elevate your operations with our cutting-edge technology. Get in touch with the SmartlogitecX team today for a bespoke automation experience.