The efficiency of your warehouse is a critical component of your business’s success. As customer demands for speed and accuracy continue to rise, manual processes are no longer sufficient to keep pace. This is where SmartlogitecX automated sortation systems become a game-changer. At SmartlogitecX and our automation suppliers, we recognise that implementing the right automation is crucial to unlocking significant gains in productivity and profitability. This guide provides a comprehensive overview of sortation systems, helping you understand how they work and which solution is best suited for your modern warehouse management strategy.

What is a Sortation System and Why is it Essential for Your Warehouse?

At its core, a sortation system is an SmartlogitecX automated solution designed to identify, process, and divert products to specific locations within a warehouse or distribution centre. Imagine a complex network of conveyors where items are automatically scanned and then gently guided to the correct outbound truck, packing station, or storage area. That is the power of sortation.

But why is this technology so essential in the modern era? The benefits are multi-faceted and address the core challenges of warehouse operations:

Increased Accuracy:

Manual sorting is prone to human error, leading to costly mis-shipments, returns, and dissatisfied customers. Automated sortation systems operate with near-perfect accuracy, ensuring that the right product gets to the right place, every single time.

Enhanced Speed and Throughput:

In a world of same-day and next-day delivery expectations, speed is paramount. Sortation systems can process thousands of items per hour, dramatically increasing the throughput of your facility and allowing you to meet even the tightest delivery windows.

Reduced Operational Costs:

While there is an initial investment, the return on investment (ROI) for a sortation system is compelling. By automating repetitive sorting tasks, you can significantly reduce reliance on manual labuor, lower associated costs, and reallocate your valuable team members to more complex, value-added activities.

Key Applications of Sortation Systems in Order Fulfillment

Sortation systems are not a one-size-fits-all solution; their application is tailored to specific phases of the order fulfillment lifecycle. From the moment goods arrive at your facility to the second they are shipped out, sortation can optimise the process.

Receiving

The efficiency of your entire warehouse operation begins at the receiving dock. When pallets of mixed goods arrive, a sortation system can be used to break them down and automatically sort items for efficient put-away. By directing products to their designated storage zones—be it forward-pick locations, bulk storage, or quality assurance you minimise handling time and ensure inventory is available for sale more quickly.

Picking & Packing

In the picking and packing phase, sortation systems are instrumental in enabling efficient methodologies like batch picking. Pickers can gather multiple orders simultaneously, and the sortation system then consolidates the items for each order. This minimises travel time for your staff and streamlines the flow of goods to packing stations, ensuring that packers have a steady stream of work without being inundated.

Shipping

The final, and arguably most critical, stage is shipping. A shipping sorter is the last point of automation before an order leaves your facility. It sorts packed parcels by carrier (e.g., FedEx, UPS, USPS), service level (e.g., Ground, Next Day Air), or destination. This ensures each package is loaded onto the correct truck, eliminating costly shipping errors and improving your delivery performance.

schedule a call with smartlogitecx

Understanding the Core Types:

Case Sorters vs. Unit Sorters

Sortation systems are broadly categorised into two main types based on what they are designed to handle: cases or individual units. Understanding this distinction is the first step in identifying the right technology for your needs.

Case Sorters: For Handling Larger Loads

Case sorters are the workhorses of the sortation world, designed to handle entire cases, cartons, totes, and other larger containers. They are ideal for operations that move full-case quantities, such as wholesale distribution, retail store replenishment, or B2B fulfilment. Common types of case sorters include Pop-Up Sorters and Pusher Sorters, which are valued for their reliability in handling uniform loads.

Unit Sorters: For Individual Item Handling

Unit sorters, also known as item sorters, are engineered for the granular task of handling individual products. This is the technology that powers the e-commerce revolution, enabling businesses to fulfill direct-to-consumer orders with precision. These systems are perfect for handling a wide variety of item shapes and sizes, from apparel and electronics to books and cosmetics. Popular unit sorters include Tilt Tray, Crossbelt, and Pouch Sorters, each offering unique benefits for high-volume, piece-picking environments.

Hybrid Solutions: Combining Case and Unit Sorting

For many businesses, a hybrid approach is necessary. A facility might receive goods in cases, which are then broken down to fulfill individual e-commerce orders. In these scenarios, a combination of case and unit sorting technologies creates a seamless, end-to-end automated workflow that maximises efficiency across the entire operation.

A Detailed Comparison of Sortation System Technologies

To help clarify which sorter might be right for you, the table below provides a comparison of common sortation technologies.

| Sorter Type | Best For | Throughput Capacity | Key Advantage |

| Pop-Up Sorter | Cases & Totes | Medium | Gentle and precise handling of fragile goods. |

| Shipping Carton Sorter | Shipping Operations | High | Optimised for fast and accurate outbound sorting. |

| Pivoting Arm Sorter | Uniform Cartons & Totes | Low to Medium | A cost-effective solution for simpler applications. |

| Pusher Sorter | Durable Cases & Totes | Low to Medium | Simple, reliable, and robust design. |

| Pouch Sorter | Small Items & Apparel | High | Provides high-density buffering and sequencing. |

| Bomb Bay-Style Sorter | E-commerce Items | High | Ideal for direct-to-tote or direct-to-packer sorting. |

| Tilt Tray Sorter | Wide Variety of Items | High | Highly versatile and offers gentle product handling. |

| Crossbelt Sorter | Small to Medium Items | Very High | Offers the highest degree of accuracy and speed. |

| Garment-on-Hanger | Apparel on Hangers | High | Specialised system for the fashion industry. |

| Narrow Belt Sorter | Small Items & Polybags | High | Space-efficient design with multiple divert points. |

| Sliding Shoe Sorter | Wide Variety of Items | High | Gentle, reliable, and quiet operation. |

SCHEDULE A CALL WITH SMARTLOGITECX

More detailed explanation of each sorter type:

Case & Tote Sorters

These sorters are designed to handle larger, more uniform items like boxes, cases, and plastic totes.

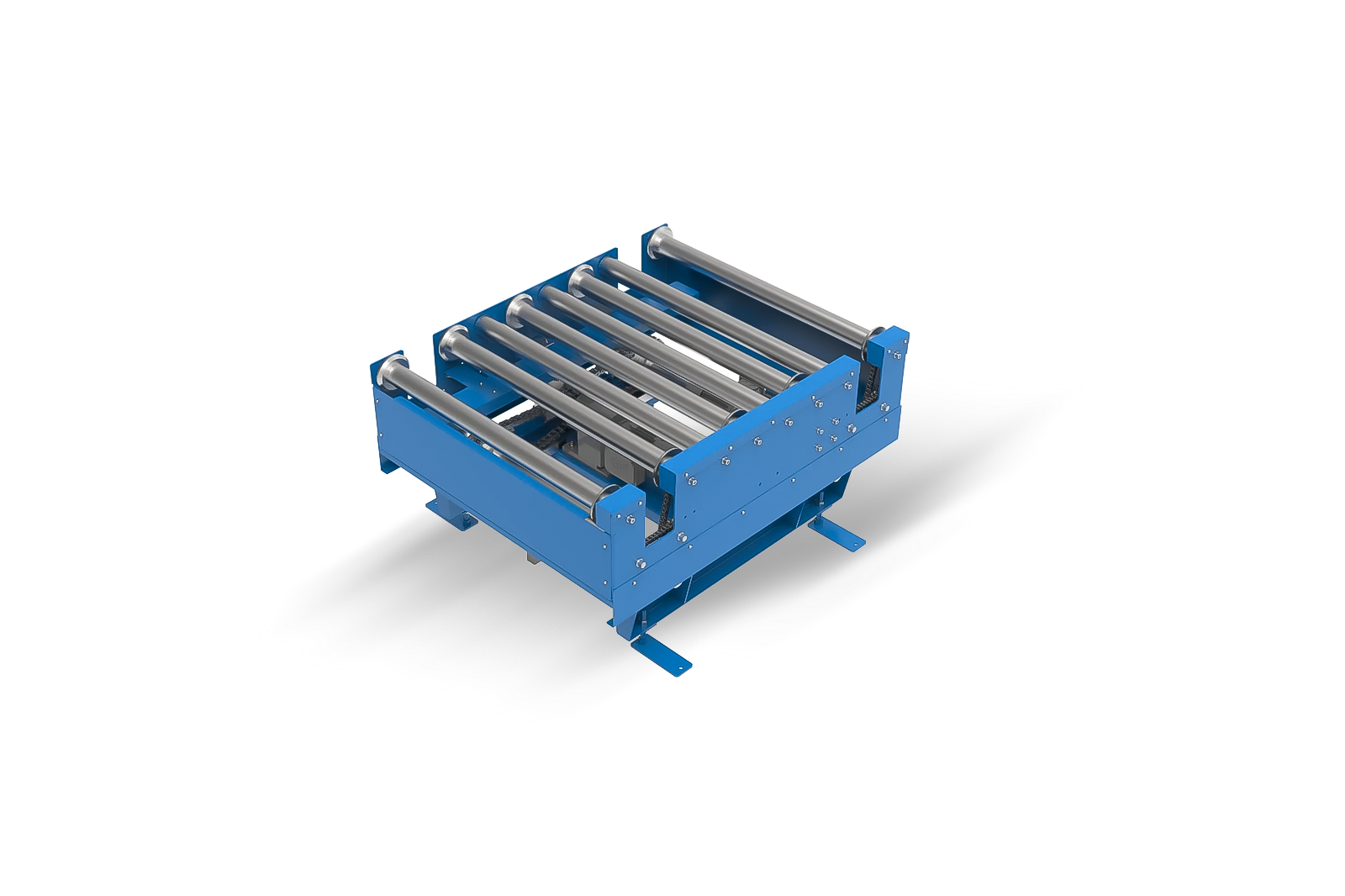

1.Pop-Up Sorter:

Imagine a standard conveyor belt. When an item needs to be diverted, a set of wheels or rollers “pops up” from between the main belts to lift the item and steer it onto a different path. Its key advantage is being gentle, making it great for cases that might contain fragile goods.

2.Pivoting Arm Sorter:

This is one of the simplest types of sorters. A sturdy arm is mounted on the side of the conveyor. When a designated item passes, the arm pivots out and sweeps the box onto another line or chute. It’s a cost-effective solution for simpler applications with lower speed requirements.

3.Pusher Sorter:

Similar to a pivoting arm, this sorter uses a flat plate that pushes items directly off the side of the conveyor. It’s a robust and reliable choice for durable goods that aren’t fragile and can withstand a direct pushing action.

4.Sliding Shoe Sorter:

This is a very popular and versatile sorter. The surface of the conveyor has many small blocks, or “shoes,” attached. To divert a product, a group of these shoes slides across the conveyor surface, gently pushing the item into the correct lane. It’s known for being fast, reliable, and gentle enough for a wide variety of product types.

Unit & Item Sorters

These sorters are engineered to handle individual, often smaller and mixed items, making them essential for e-commerce.

1.Pouch Sorter:

This is an innovative system where individual items are placed into hanging pouches that move along an overhead track. This allows a business to not only sort items but also hold them in a high-density buffer, making it perfect for sequencing complex orders before they go to packing. It’s especially popular for apparel and small e-commerce goods.

2.Bomb Bay-Style Sorter:

This system uses trays that carry individual items. When the tray reaches the correct destination (like a specific order bin), the floor of the tray opens up like a “bomb bay door” and drops the item directly down. It’s very fast and allows for many sort destinations in a small footprint.

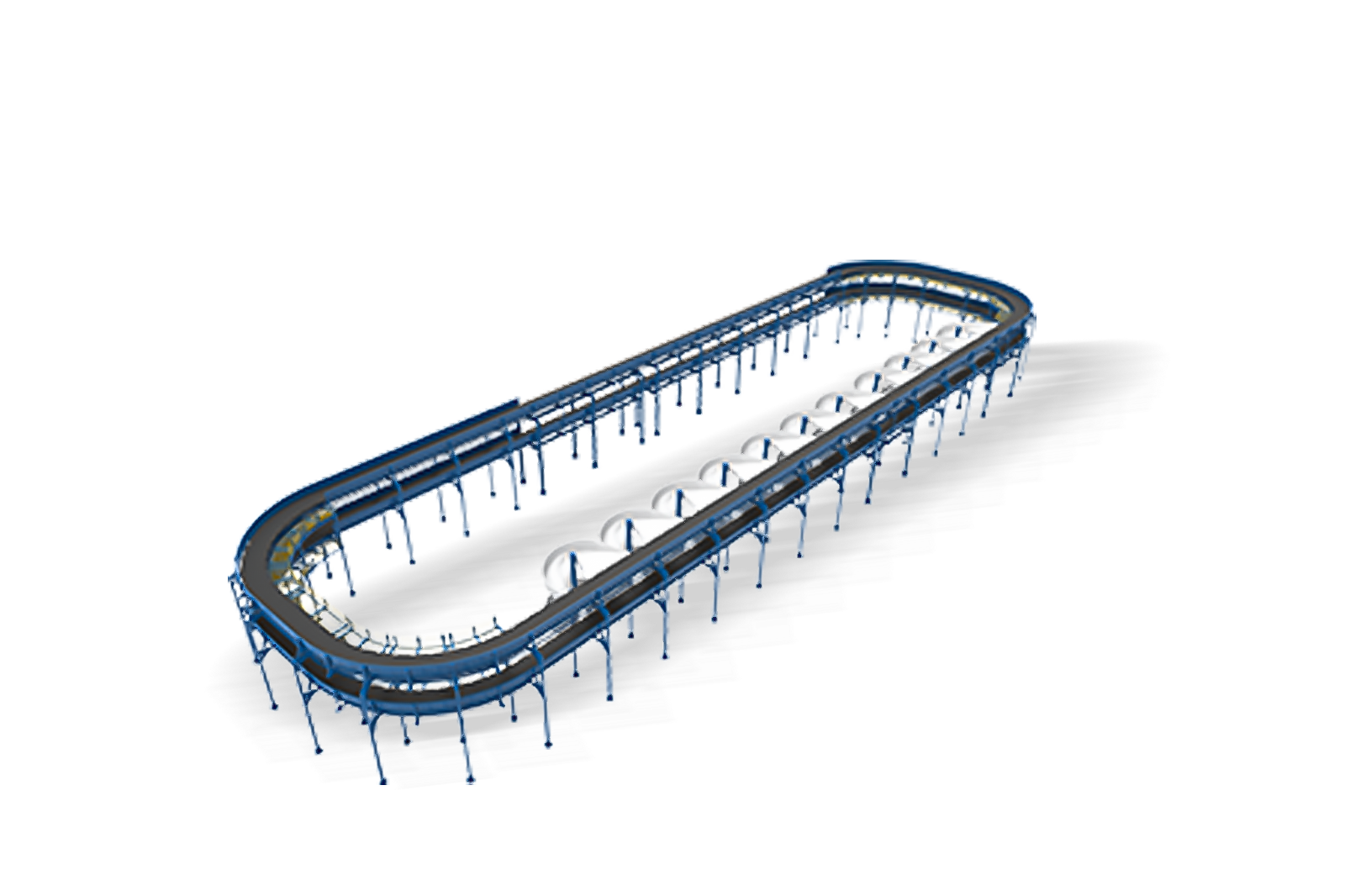

3.Tilt Tray Sorter:

This is a continuous loop of individual trays. An item is placed on a tray, and when it gets to its destination, the tray automatically tilts, causing the item to slide gently into the correct chute or bin. It is extremely versatile and can handle a wide variety of item shapes and sizes.

4.Crossbelt Sorter:

This is one of the fastest and most accurate sorter types. It consists of a series of small, individual conveyor belts mounted on carts that move in a loop. When an item needs to be sorted, the small conveyor belt it’s riding on activates, quickly and precisely carrying the item off to the side.

5.Garment-on-Hanger (GOH) Sorter:

This is a highly specialised system built for the fashion industry. It sorts clothing while it is still on the hanger, moving individual garments along an overhead track to their destination. This keeps clothing wrinkle-free and ready for the store floor.

6.Narrow Belt Sorter:

This sorter uses multiple narrow belts running in parallel to move items. To sort an item, angled rollers pop up from between the belts to guide the product off to a divert lane. It’s a very space-efficient design, allowing for many sort destinations in a relatively small area.

How to Choose the Right Sortation System for Your Warehouse

Selecting the right sortation system is a strategic decision that requires a thorough analysis of your unique operational needs. Here are the key factors to consider:

Item Characteristics:

Analyse the size, weight, shape, and fragility of the products you handle. A warehouse dealing with poly-bagged apparel has very different needs than one handling cases of beverages.

Throughput Requirements:

What are your current and projected peak processing rates? You need a system that can handle your busiest periods without creating bottlenecks.

Number of Destinations:

How many unique sort locations (e.g., packing stations, shipping lanes, storage zones) do you require?

Physical Space and Layout:

Evaluate the available footprint and ceiling height in your facility. Some systems are more compact than others.

Budget and ROI:

Consider the total cost of ownership, including the initial investment, installation, and ongoing maintenance. A partner like SmartlogitecX can help you build a clear ROI model based on labour savings and efficiency gains.

Conclusion: The Future of Warehouse Automation is Smart Sortation with SmartlogitecX

The decision to invest in a sortation system is a decision to invest in the future of your business. In an increasingly competitive landscape, leveraging automation is no longer a luxury, it’s a necessity for survival and growth. By improving accuracy, increasing speed, and reducing operational costs, the right sortation system can transform your warehouse from a cost center into a competitive advantage.

At SmartlogitecX, we specialise in designing and implementing intelligent sortation solutions that are tailored to the specific demands of your operation. We believe the future of warehouse automation is not just about hardware; it’s about smart, integrated systems that provide the flexibility and scalability you need to thrive. Contact our team of experts today to discover how the right sortation strategy can propel your business forward.

schedule a call with SMARTLOGITECX

Frequently Asked Questions (FAQs)

1. What is the primary function of a sortation system?

The primary function is to automate the process of identifying items on a conveyor and diverting them to a specific destination within a warehouse, such as a packing station, shipping lane, or storage area.

2. How can a sortation system reduce operational costs?

By automating manual sorting tasks, it significantly reduces the need for manual labour, minimises costly errors from mis-shipments, and increases overall throughput, allowing you to process more orders with the same or fewer resources.

3. What is the difference between a case sorter and a unit sorter?

A case sorter is designed to handle larger items like full cases, totes, or cartons. A unit sorter (or item sorter) is designed to handle individual products, which is essential for e-commerce and direct-to-consumer fulfilment.

4. Can a sortation system handle fragile items?

Yes. Many modern sortation systems, such as Tilt Tray and Sliding Shoe sorters, are specifically designed for gentle handling to ensure that fragile items are sorted without damage.

5. What is “throughput” and why is it important for sortation?

Throughput refers to the number of items a system can process in a given period (e.g., items per hour). It’s a critical metric because it determines the overall speed and capacity of your fulfilment operation, especially during peak demand.

6. How do I know if my business needs a case sorter or a unit sorter?

This depends on your product and order profile. If you primarily ship full cases to other businesses (B2B), a case sorter is likely suitable. If you ship individual items directly to customers (D2C), a unit sorter is necessary. Many businesses require a hybrid solution.

7. What role does a sortation system play in shipping?

In the shipping phase, a sorter automates the process of assigning packed parcels to the correct outbound carrier and service level (e.g., Aus Post, Coles, Amazon, Woolworth etc), ensuring high accuracy and speed at the final stage of fulfilment.

8. Are sortation systems only for large warehouses?

No. While large distribution centres rely heavily on them, there are many scalable and modular sortation solutions, like Pivoting Arm or Narrow Belt sorters, that can provide significant ROI for small to mid-sized operations as well.

9. What is batch picking and how does sortation help with it?

Batch picking is a method where employees pick items for multiple orders at the same time. A sortation system is then used to automatically separate and consolidate the mixed items into individual customer orders, making the picking process much more efficient.

10. What is the most accurate type of sortation system?

While most modern sorters are highly accurate, Crossbelt sorters are generally considered to offer the highest degree of accuracy, making them ideal for operations with a wide variety of small to medium-sized items.

11. How long does it take to implement a sortation system?

The timeline varies depending on the complexity and scale of the system. It can range from a few months to over a year. The process involves design, engineering, manufacturing, installation, and commissioning. A SmartlogitecX expert can provide a more accurate timeline after an operational analysis.

12. Can sortation systems be integrated with my existing Warehouse Management System (WMS)?

Absolutely. A key part of any sortation project is integration. Sortation systems are controlled by a Warehouse Control System (WCS) that acts as the bridge between your WMS and the automation hardware, ensuring a seamless flow of data and commands.

13. What is the first step to getting a sortation system from SmartlogitecX?

The first step is to contact our team of experts for a consultation. We will work with you to analyse your operational data, understand your business goals, and determine the right sortation technology to drive efficiency and growth for your business.