In the age of instant gratification and e-commerce dominance, the speed and efficiency of logistics have become paramount. Gone are the days of slow, manual sorting processes; automated sortation systems are now the driving force behind streamlined package delivery, order fulfillment, and warehouse operations. These intelligent machines are transforming the industry, offering a glimpse into a future where robots rule the sorting room.

What are Automated Sortation Systems?

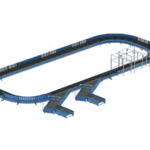

Imagine a conveyor belt bussing with packages, each one whisked away to its designated destination with laser-like precision. That’s the essence of an automated sortation system. These complex systems leverage a combination of technologies, including:

- Conveyor belts: The workhorses of the system, transporting packages to various sorting stations.

- Scanners: Identifying barcodes, QR codes, or RFID tags on packages to determine their destination.

- Sorters: Diverting packages onto the correct conveyor belt or chute based on the scanned information.

- Software: The brain of the operation, controlling the flow of packages and optimising sorting algorithms.

Benefits of Automated Sortation Systems

The advantages of automated sortation systems are numerous and far-reaching.

- Increased Speed and Efficiency: Machines can sort packages significantly faster than humans, leading to shorter delivery times and increased order fulfillment capacity.

- Reduced Costs: Automation eliminates the need for manual labor, lowering operational costs and improving resource utilisation.

- Improved Accuracy: Precise scanning and sorting systems minimise errors, leading to fewer lost or misdirected packages.

- Enhanced Scalability: Systems can be easily expanded to accommodate growing demand, making them ideal for businesses with fluctuating package volumes.

- Increased Worker Safety: Automation removes the risk of repetitive strain injuries and other workplace hasards associated with manual sorting.

Types of Automated Sortation Systems

Not all automated sortation systems are created equal. The specific type chosen depends on the needs and budget of the operation. Some popular options include;

- Belt sorters: Ideal for high-volume sorting of small packages, utilising belts with divert mechanisms to separate items.

- Tilt-tray sorters: Gentle on fragile items, these systems use trays that tilt to direct packages onto the correct lane.

- Cross-belt sorters: Offering flexibility for sorting both large and small packages, these systems utilise intersecting conveyor belts to divert items.

- Robotic sorters: Emerging technology, robots can handle delicate or oddly shaped packages, offering greater precision and flexibility.

The Future of Automated Sortation

As technology advances, automated sortation systems will become even more sophisticated. Expect to see:

- Increased integration with artificial intelligence (AI): AI-powered systems can learn and adapt to optimise sorting algorithms in real-time.

- Wider adoption of robotics: Robots will become more versatile and cost-effective, handling a broader range of sorting tasks.

- Greater focus on sustainability: Energy-efficient systems and eco-friendly materials will be prioritised to reduce the environmental impact of sorting operations.

FAQs

- What is the cost of an automated sortation system?

The cost varies depending on the size, complexity, and type of system. However, even smaller systems can offer significant ROI through increased efficiency and cost savings. - How much space do automated sortation systems require?

The space requirement depends on the system’s capacity and layout. Some systems can be implemented in relatively small spaces, while others may require dedicated facilities. - Do automated sortation systems require skilled operators?

While some technical expertise is needed for maintenance and troubleshooting, most systems can be operated with minimal training. - Can automated sortation systems handle all types of packages?

The capabilities of systems vary, but most can handle a wide range of package sizes, shapes, and weights. However, some specialised items may require manual sorting. - Are automated sortation systems safe for workers?

Properly designed and implemented systems pose minimal risk to workers. Safety features like sensors and automated shutdowns help prevent accidents.

The Rise of the Machines is Here to Stay

Automated sortation systems are not just a futuristic concept; they are the present and future of logistics. By embracing this technology, businesses can achieve unprecedented levels of efficiency, accuracy, and cost savings, propelling them towards success in the ever-evolving world of e-commerce and fast-paced delivery. So buckle up, fasten your seatbelts, and prepare for a smoother, faster ride through the world of logistics, courtesy of the remarkable machines that are revolutionising the way we sort and deliver.

Empower your logistics with SmartlogitecX, fueled by WayZim Technologies. As leaders in Warehouse Automation for the Australian market, we’re dedicated to delivering efficiency and innovation right to your doorstep. SmartlogitecX’s approach is two-fold: globally informed, locally applied. Take the first step towards optimised operations by reaching out to our sales team for a solution that speaks directly to your needs.