The Pallet, loader, pallet conveyors, and horizontal diverter/merge unit are crucial elements of individual carrier systems, playing vital roles in their operations. This article will delve into the core standalone equipment of the Individual Carrier System (ICS).

The loader is the starting point for the ICS to handle baggage.

The upper belt conveyor conveys baggage, and the lower pallet conveyor conveys the pallets synchronously. The baggage is accurately loaded into the lower pallets from the upper belt conveyor, and baggage barcode information and pallet information are bound.

Pallet conveyors include linear pallet conveyors, incline pallet conveyors, and curve pallet conveyors which respectively transport pallets in the horizontal section, uphill/downhill inclined section, and turning section connecting adjacent linear pallet conveyors.

The 30° horizontal diverter/merge unit consists of linear pallet conveyors, a 30° diverters/merge units, and a 30° guide device. The diverter divides pallets from one conveyor line into two conveyor lines, while the merge unit merges pallets from two conveyor lines onto one main conveyor line, switching pallet conveying paths as required.

The 90° transfer sorter is installed in the track of the linear pallet conveyor, switching the pallet conveying path through equipment lifting and lowering.

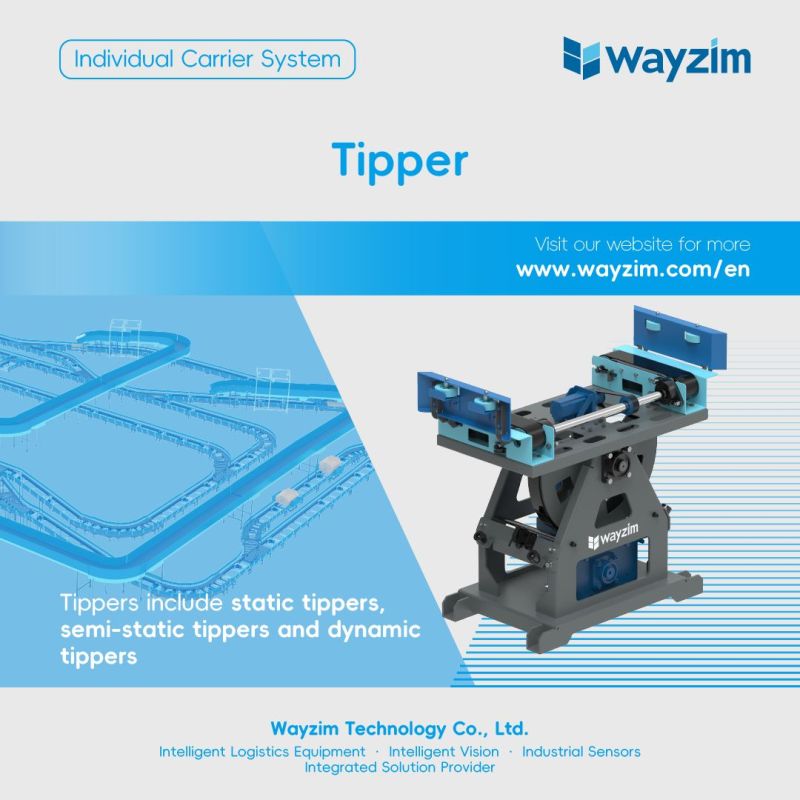

The tipper is end sorting equipment for separating baggage from pallets to chutes. The static tipper sorts baggage when pallets are static, the semi-static tipper sorts baggage when pallets are decelerated to low speed, and the dynamic tipper sorts baggage when pallets are not decelerated.

The stacker/destacker is automated logistics equipment used for stacking and destacking empty pallets.

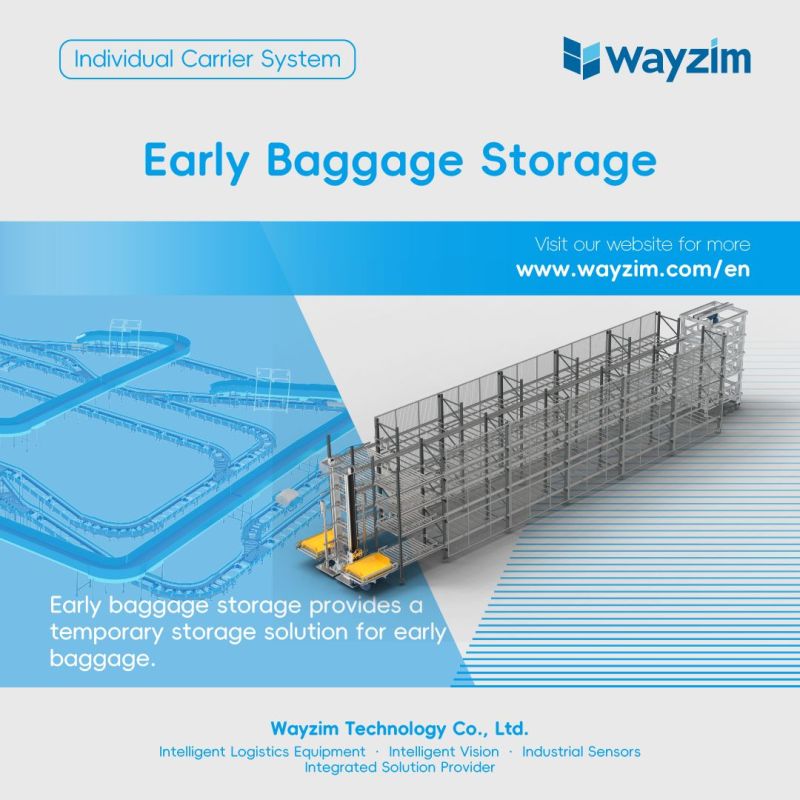

Early baggage storage in the ICS provides a temporary storage solution for early baggage, and conveys the baggage together to the sorting system before the aircraft takes off, improving baggage handling efficiency.

SmartlogitecX, empowered by WayZim Technologies, is at the forefront of revolutionising Warehouse Automation in the Australian and New Zealand market. Be part of the logistics transformation. Embrace SmartlogitecX’s locally-focused, globally-backed expertise. Redefine your operations, harnessing the power of technology made for the Australian and New Zealand. Ready to elevate your logistics? Reach out to the SmartlogitecX sales team for your customised automation solution.