Modern warehouses face unprecedented challenges in today’s fast-paced logistics landscape, with studies showing that implementing SmartlogitecX Automated Guided Vehicles (AGVs) can boost operational efficiency by up to 30%, transforming how businesses approach warehouse automation. As labour shortages continue to plague the industry and operational costs spiral upward, warehouse managers are increasingly turning to innovative warehouse solutions to meet the relentless demand for faster fulfilment whilst maintaining competitive margins. The pressure to optimise logistics operations has never been more intense, with e-commerce growth driving expectations for next-day and even same-day delivery across Australia. AGVs represent a powerful solution to these mounting challenges, offering a proven pathway to enhanced productivity, reduced costs, and improved workplace safety. This comprehensive guide will walk you through everything you need to know about implementing AGVs in your warehouse operations, from understanding the fundamental technology to successfully deploying these game-changing automation systems.

What Are Automated Guided Vehicles and How Do They Work

Automated Guided Vehicles are sophisticated driverless, computer-controlled vehicles designed specifically for transporting materials throughout warehouse and manufacturing facilities, representing a cornerstone of modern warehouse robotics that fundamentally transforms material handling operations. At their core, AGVs consist of several essential components working in harmony:

- Advanced navigation systems that guide movement with precision accuracy

- Comprehensive sensor arrays ensuring safety through obstacle detection and collision avoidance

- Intuitive control interfaces that seamlessly integrate with existing warehouse management systems

- Communication modules enabling real-time coordination with other equipment

The navigation technology varies depending on specific application requirements, with popular options including Laser SLAM (Simultaneous Localisation and Mapping) that creates dynamic facility maps, magnetic tape guidance offering reliable and cost-effective pathfinding, and sophisticated vision guidance systems that use cameras and artificial intelligence to navigate complex environments. These automation solutions excel at handling repetitive transport tasks that would otherwise consume valuable human resources, allowing warehouse staff to focus on more complex, value-added activities such as quality control, problem-solving, and customer service. The SmartlogitecX AGV technology continuously evolves, with manufacturers incorporating machine learning algorithms and advanced sensors to improve navigation accuracy, enhance safety protocols, and optimise route planning for maximum efficiency.

Key Benefits of AGVs in Warehouse Operations

The implementation of automated warehouse solutions delivers transformative benefits across multiple operational dimensions, fundamentally reshaping how modern facilities approach material handling and logistics management. These key advantages include:

Increased Productivity:

AGVs operate 24/7 without breaks, maintaining consistent performance that reduces cycle times by up to 40% and dramatically boosts throughput in optimised environments

Reduced Labour Costs:

Automating manual transport tasks generates savings of 20-30% on wages and associated expenses whilst addressing chronic labour shortages affecting Australian warehouses

Enhanced Workplace Safety:

Advanced sensor systems and predictable movement patterns reduce material handling accidents by up to 70% compared to traditional forklift operations

Improved Accuracy and Precision:

Virtual elimination of human error reduces misplaced inventory by 60% and significantly decreases product damage during transport

Flexible and Scalable Operations:

Easy expansion or reconfiguration of AGV systems provides essential agility for seasonal fluctuations or business growth without major infrastructure overhauls

Better Space Optimisation:

AGVs operate in aisles 30% narrower than traditional equipment requires, enabling denser storage configurations that maximise valuable warehouse real estate

These warehouse automation solutions create a compound effect, where each benefit reinforces others to deliver exceptional ROI and operational excellence that directly impacts the bottom line through reduced waste, improved customer satisfaction, and enhanced competitive positioning.

A Guide to Different Types of AGV Systems

Understanding the diverse range of warehouse automation products available is crucial for selecting the optimal solution for your specific operational requirements, as not all AGVs are created equal and each type excels in different applications.

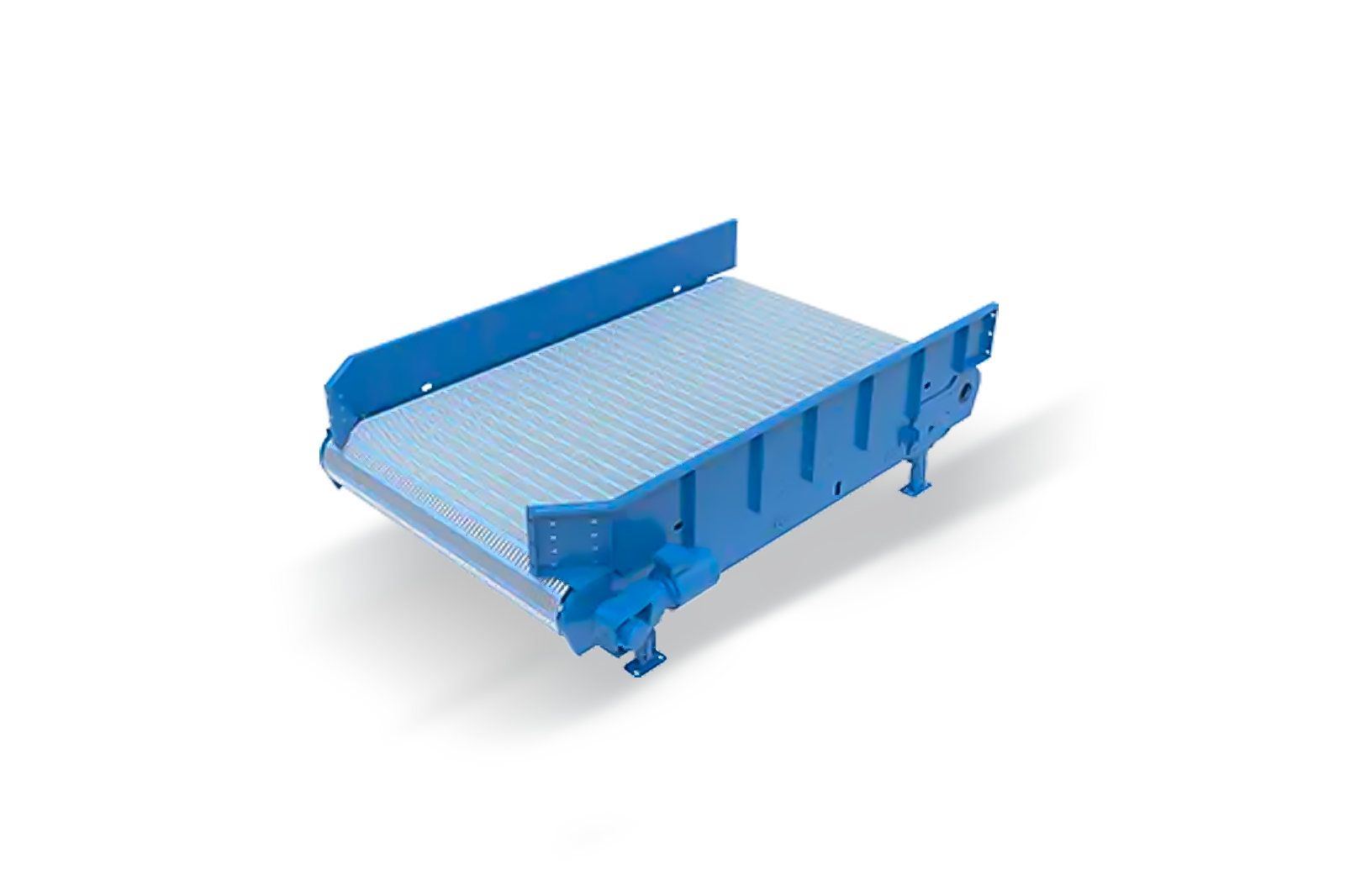

Fork AGVs

Fork AGVs represent the workhorses of automated pallet handling, designed to automatically lift and transport pallets with impressive capabilities. Their key characteristics include: • Handling loads up to 2000kg with consistent precision • Performing essential tasks like pallet racking and block stacking • Seamlessly moving goods from production to storage or shipping • Operating effectively in lights-out environments • Replicating traditional forklift functionality with enhanced safety

Also known as under-ride or tugger AGVs, these systems offer exceptional flexibility by moving carts or shelves from underneath. Their advantages encompass: • Ideal for goods-to-person workflows in e-commerce fulfilment • Omnidirectional movement capabilities for congested areas • Ability to transport multiple carts simultaneously • Excellent for environments requiring frequent route changes • Superior performance in dynamic order picking operations

When comparing these warehouse robotics systems, Fork AGVs typically suit operations with standardised pallet movements and heavy loads, whilst Latent AGVs prove invaluable in dynamic environments requiring flexibility and frequent reconfiguration, often serving as superior alternatives or complementary solutions to traditional warehouse conveyor systems.

Essential Steps for a Successful AGV Implementation

Deploying automated warehouse systems requires a methodical approach that ensures seamless integration with existing operations whilst maximising return on investment. Follow these critical steps:

Step 1: Assess Your Operations

- Conduct comprehensive workflow analysis to identify bottlenecks • Map current material flows and transport patterns • Establish clear automation objectives aligned with business goals • Quantify expected benefits and success metrics

Step 2: Choose the Right AGV Solution

- Evaluate assessment findings against available AGV types • Consider load characteristics and throughput requirements • Analyse facility layout and navigation technology options • Factor in future scalability and expansion needs

Step 3: Prepare Your Facility

- Ensure floor conditions meet AGV specifications • Establish robust network connectivity infrastructure • Optimise layouts for AGV travel paths • Designate appropriate charging station locations

Step 4: Plan for Integration

- Connect AGV control systems with existing WMS platforms • Coordinate between IT teams and automation vendors • Ensure proper data flow and operational visibility • Configure task allocation and priority rules

Step 5: Implement and Test

- Complete physical installation of all equipment • Conduct comprehensive system commissioning • Perform rigorous testing in controlled environments • Verify performance metrics and safety protocols

Step 6: Train Your Team

- Develop comprehensive training programmes for all staff levels • Foster understanding of human-AGV collaboration • Build maintenance and troubleshooting capabilities • Create culture of continuous improvement.

Overcoming Common AGV Implementation Challenges

Successfully navigating potential obstacles during AGV deployment requires proactive planning and realistic expectations about the challenges that may arise. Key challenges and their solutions include:

High Initial Investment

- Typical payback periods of 18-24 months justify the investment • Factor in labour savings, increased throughput, and reduced errors • Consider financing options and government automation grants • Calculate total cost of ownership versus operational benefits

System Integration Complexity

- Partner with experienced integration specialists • Utilise middleware solutions for legacy system connections • Implement phased integration approaches • Maintain clear communication protocols between systems

Infrastructure Readiness

- Address uneven floors through resurfacing or specialised suspension • Install mesh networks for reliable wireless coverage • Implement 5S methodologies to create organised environments • Establish clear pathways and designated AGV zones

Employee Adoption and Change Management

- Communicate how AGVs augment rather than replace human roles • Involve floor staff in planning and implementation processes • Provide comprehensive training to build confidence • Celebrate early wins to build momentum and support

These proactive approaches to common challenges ensure smoother implementation and faster realisation of warehouse automation benefits.

Final Thoughts on Boosting Your Warehouse Performance

Implementing AGVs represents a strategic investment in the future of your warehouse operations, delivering measurable improvements in efficiency, safety, and scalability that position your business for long-term success in an increasingly competitive marketplace. The journey to successful warehouse automation requires careful planning, thoughtful technology selection, and effective change management, but organisations that commit to this transformation consistently report significant competitive advantages including:

- Reduced operational costs of 20-30% annually

- Improved customer satisfaction through 99%+ order accuracy

- Enhanced ability to scale without proportional labour increases

- Strengthened market position through operational excellence

- Future-proof infrastructure ready for continued advancement

As the logistics industry continues evolving, early adopters of automated warehouse solutions like those offered by SmartlogitecX are already reaping the benefits of increased productivity and operational excellence, whilst those hesitating risk falling behind competitors who embrace these warehouse solutions. The future of warehousing undoubtedly involves greater automation, and AGVs represent a proven, accessible entry point into this future-proof approach to material handling that delivers immediate benefits whilst laying the foundation for continued technological advancement.

Frequently Asked Questions

1.How much does an AGV system typically cost?

AGV system costs vary significantly based on complexity and scale, typically ranging from $40,000 to $150,000 per vehicle, with additional expenses for infrastructure modifications, software integration, and training. Total project costs for a medium-sized Australian warehouse implementing 5-10 AGVs generally fall between $500,000 and $2 million, though financing options and government automation grants can help manage the initial investment.

2.What is the return on investment for AGVs in a warehouse?

Most warehouses achieve ROI within 18-24 months through combined savings in labour costs, reduced product damage, improved space utilisation, and increased throughput. A typical Australian facility can expect annual savings of 20-30% on operational costs, with some high-volume operations reporting payback periods as short as 12 months.

3.How do AGVs integrate with an existing Warehouse Management System (WMS)?

AGVs communicate with WMS platforms through standardised protocols like API connections or middleware solutions that translate commands between systems. The integration process typically involves mapping AGV capabilities to WMS functions, establishing communication protocols, and configuring task allocation rules to ensure seamless coordination between automated and manual operations.

4.What are the main safety features of modern AGVs?

Contemporary AGVs incorporate multiple safety systems including 360-degree laser scanners, emergency stop buttons, audible and visual warning signals, speed control in populated areas, and sophisticated collision avoidance algorithms. These features work together to create a safety rating that exceeds traditional material handling equipment, with most systems achieving SIL-2 or SIL-3 safety integrity levels.

5.Can AGVs work alongside human employees safely?

Yes, modern AGVs are specifically designed for collaborative environments, using advanced sensors to detect human presence and adjust their behaviour accordingly. Safety protocols include automatic speed reduction near personnel, designated crossing zones, and clear visual/audio warnings, creating a harmonious workspace where humans and machines operate efficiently together.

6.What kind of maintenance do AGVs require?

AGVs typically require preventive maintenance every 500-1000 operating hours, including battery care, sensor cleaning, software updates, and mechanical inspections. Most systems feature predictive maintenance capabilities that alert operators to potential issues before failures occur, with annual maintenance costs averaging 5-10% of the initial investment.

7.How long does it take to implement an AGV system?

Implementation timelines vary based on system complexity, but most projects complete within 3-6 months from initial assessment to full operation. Simple deployments with standard AGVs might take 8-12 weeks, whilst custom solutions requiring significant infrastructure modifications or complex integrations can extend to 9-12 months.

8.What is the difference between an AGV and an Autonomous Mobile Robot (AMR)?

AGVs follow predetermined paths using fixed navigation infrastructure like magnetic tape or reflectors, whilst AMRs use dynamic navigation to create their own paths using onboard intelligence and environmental mapping. AMRs offer greater flexibility but typically cost 20-40% more than AGVs and may require more sophisticated integration.

9. Are AGVs suitable for small to medium-sized businesses?

Absolutely, with scalable solutions now available starting from single-vehicle deployments that can grow with your business. Many Australian SMEs successfully implement AGVs by beginning with high-impact applications like goods-to-person picking or repetitive long-distance transport, achieving similar ROI percentages to larger operations.

10.What happens if an obstacle blocks an AGV’s path?

When encountering unexpected obstacles, AGVs immediately stop and attempt alternative routes if available, or send alerts to operators if intervention is required. Advanced systems can dynamically recalculate paths, communicate with other AGVs to avoid congestion, and even learn from repeated obstacles to optimise future routing decisions.