Australian warehouses face mounting pressure from every direction. Labour costs have risen sharply, industrial real estate prices continue climbing, and e-commerce demand shows no signs of slowing. For operations managers navigating these challenges, achieving significant cost reductions is no longer a competitive advantage—it’s essential for survival.

SmartlogitecX warehouse automation offers a proven path forward. By targeting key inefficiencies and unlocking new productivity levels, automated systems can deliver operational cost savings of up to 30%. This guide breaks down exactly how those savings are achieved and provides practical steps to begin your automation journey.

The Core Areas for Major Operational Cost Savings

Understanding where the 30% cost reduction comes from requires examining three high-impact areas that automation addresses directly.

Slashing Labour Costs with Robotic Systems

Labour represents one of the largest line items in warehouse budgets, and warehouse robotics tackles this expense head-on. Robotic systems—including SmartlogitecX Autonomous Mobile Robots (AMRs) and robotic picking arms—handle repetitive, labour-intensive tasks such as picking, packing, and transporting goods across the facility floor.

This technology reduces dependency on manual labour, which proves particularly valuable given ongoing workforce shortages affecting Australian logistics operations. SmartlogitecX’s robotic warehouse management systems have documented a 20-40% reduction in manual picking and transport costs for facilities that implement these solutions.

Beyond direct wage savings, reducing labour costs with warehouse automation also decreases expenses related to recruitment, training, workplace injuries, and staff turnover—costs that often remain hidden in traditional operational budgets.

Maximising Space with Automated Storage Solutions

Rising industrial real estate prices across Australian metropolitan areas make space utilisation a critical cost factor. Every square metre of warehouse floor carries significant rental or ownership costs.

Automated Storage and Retrieval Systems (ASRS) address this challenge by leveraging vertical space that traditional shelving cannot access. These systems dramatically increase storage density within the same footprint, allowing facilities to store more inventory without expanding their physical premises.

The impact can be substantial. SmartlogitecX’s automated storage solutions have demonstrated the ability to recover up to 85% of floor space in comparable facilities. For a warehouse paying $150 per square metre annually, that recovered space translates directly to bottom-line savings or additional revenue-generating capacity.

Boosting Accuracy to Minimise Costly Errors

Human error in warehousing creates a financial drain that compounds over time. Mis-picks, incorrect shipments, and returns processing consume labour hours, generate shipping costs, and damage customer relationships.

Warehouse automation solutions such as Intelligent Vision Systems and automated sortation achieve near-perfect accuracy—up to 99.9% in optimised configurations. This improvement connects directly to measurable cost savings through reduced returns, fewer re-shipments, and higher customer satisfaction scores that protect long-term revenue.

For facilities processing thousands of orders daily, even a small percentage improvement in picking accuracy prevents hundreds of costly errors each month.

A Practical Guide to Key Automation Technologies

Selecting the right technology requires understanding what each system does and where it delivers the greatest value.

ASRS Automated Storage and Retrieval Systems Explained

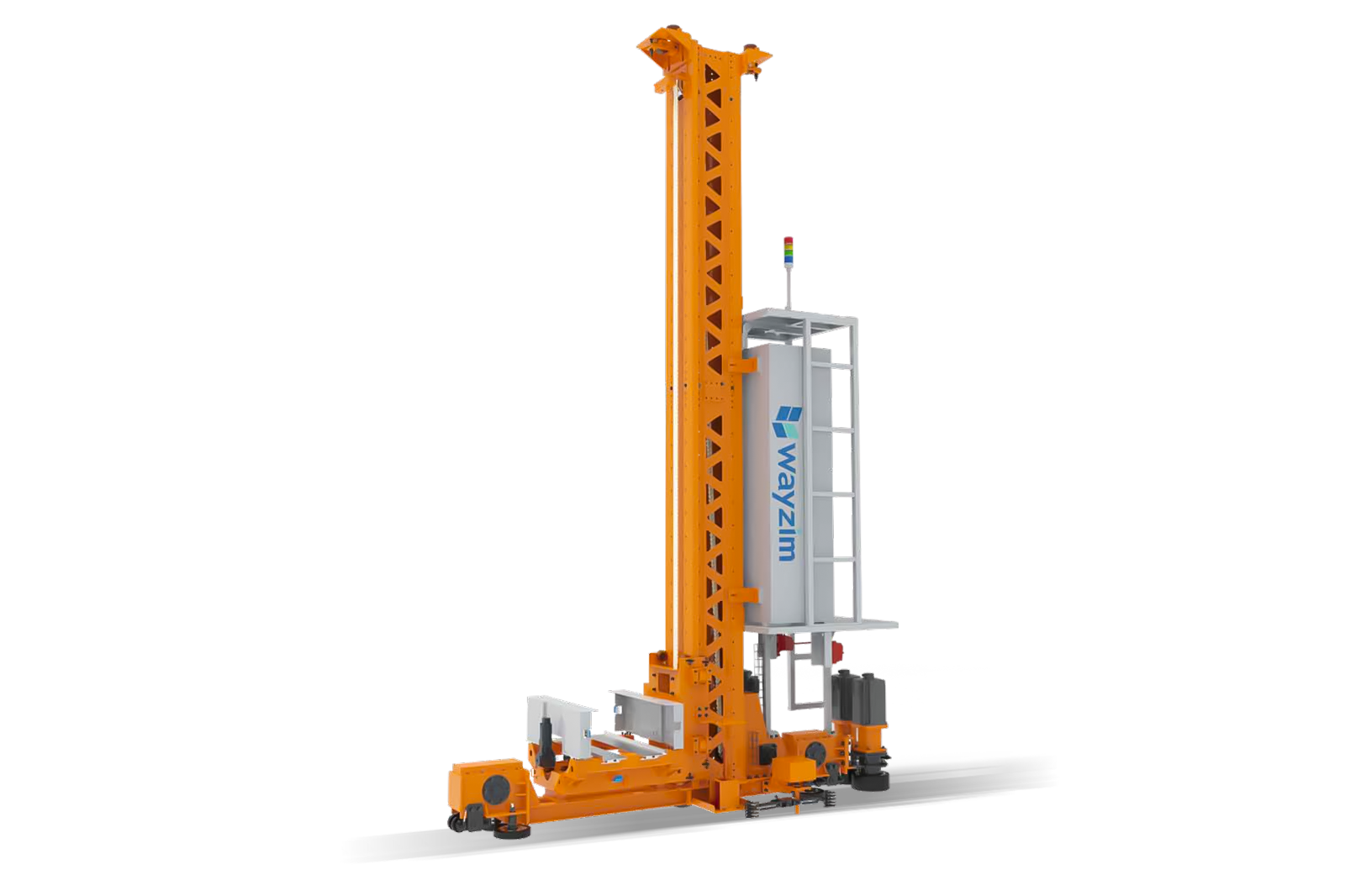

An ASRS automated storage and retrieval system uses cranes, shuttles, and integrated software to automatically store and retrieve goods from high-density racking structures. These automated warehouse systems eliminate the need for workers to physically travel through aisles locating products.

Different configurations serve different needs. Unit-load systems handle full pallets efficiently, making them ideal for bulk storage operations. Mini-load systems manage smaller items and totes, suiting e-commerce and parts distribution facilities. Both deliver high-density storage, rapid retrieval times, and reduced manual handling.

The Role of AMRs and AGVs in Modern Warehousing

Warehouse AMR technology and Automated Guided Vehicles (AGVs) both transport goods through facilities, but they operate differently. AGVs follow fixed paths—typically magnetic tape or wire embedded in the floor. AMRs navigate dynamically using sensors and mapping software, allowing them to avoid obstacles and find efficient routes in real time.

Common applications include transporting goods from storage to packing stations, enabling goods-to-person fulfilment workflows, and reducing foot traffic congestion. Their flexibility and scalability make them suitable for various warehouse layouts and fluctuating seasonal demand—particularly relevant for Australian retail operations managing holiday peaks.

Smart Conveyor and Automated Sortation Systems

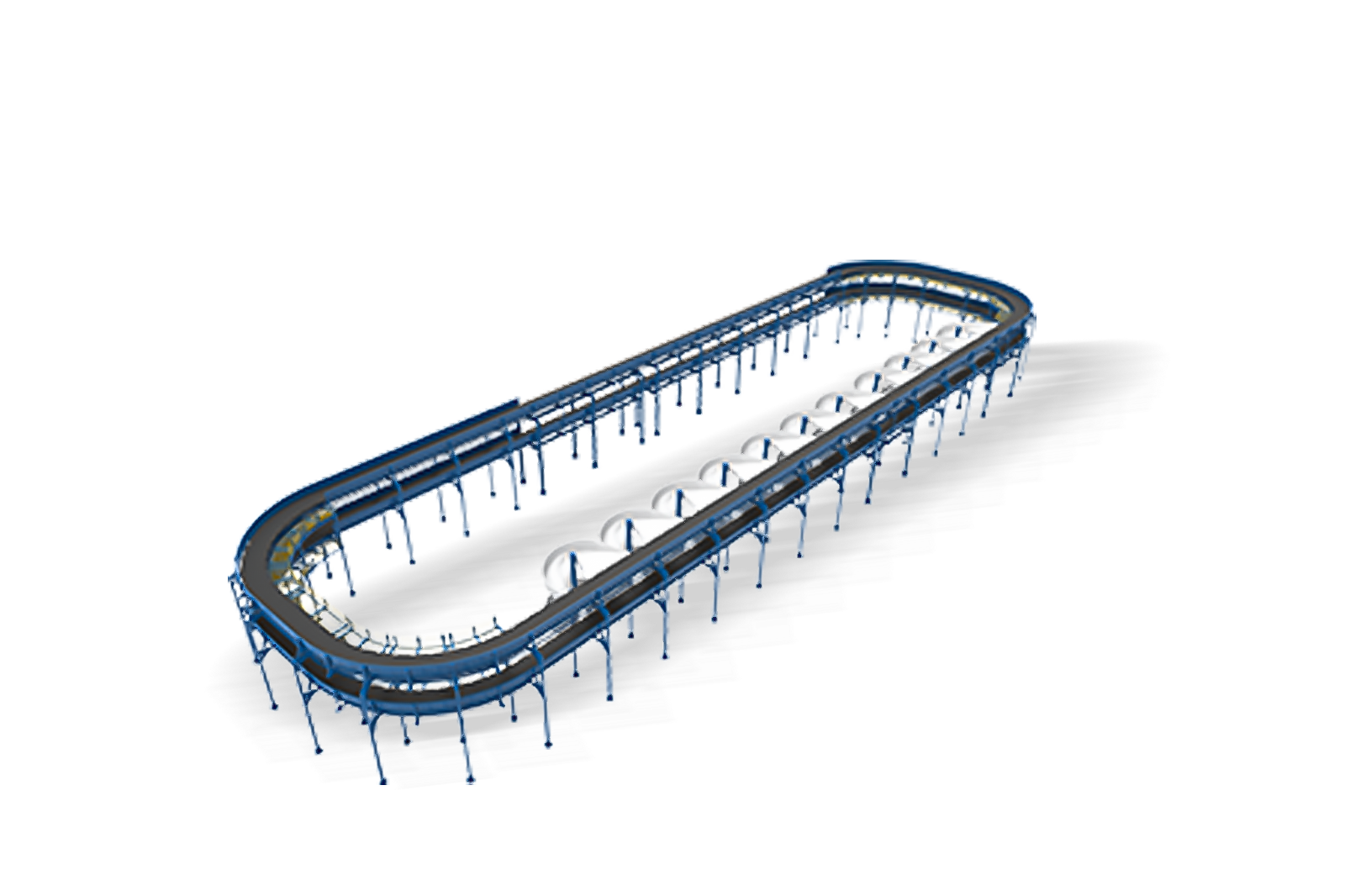

Warehouse conveyor systems and automated sortation equipment streamline the flow of goods through processing stages. Modern automated warehouse conveyor systems integrate with barcode scanning and warehouse management software to ensure products route correctly for packing and shipping.

Sortation technologies—including Pivot Wheel and Cross-Belt Sorters—handle high volumes essential for e-commerce fulfilment centres. These systems process thousands of items per hour with consistent accuracy, enabling facilities to scale throughput without proportionally increasing labour costs.

Steps for a Successful Automation Implementation

Moving from understanding to action requires a structured approach that manages risk while capturing benefits.

1. Identifying the Right Processes to Automate First

Begin with a process audit to identify your facility’s biggest bottlenecks and most repetitive tasks. Not every process benefits equally from automation. Focus initial investments on high-impact areas—picking, sorting, or palletising—where you’ll see the quickest return.

A phased implementation approach manages costs and minimises operational disruption. Start with warehouse automation products that address your most pressing pain points, then expand as you demonstrate success and build internal expertise.

2. Building a Business Case and Calculating ROI

A robust business case for automation investment includes several components. When calculating return on investment, factor in labour savings, increased throughput capacity, error reduction, and improved safety metrics. Many facilities achieve payback within 1-3 years, though results vary based on project scope and local conditions.

For operations with capital constraints, Robotics as a Service (RaaS) models lower the initial investment barrier. These arrangements convert large capital expenditures into manageable operational costs, making automation accessible to mid-sized Australian facilities.

Final Thoughts on Achieving Significant Cost Reductions

Warehouse automation delivers measurable cost savings through reduced labor dependency, optimised space utilisation, and enhanced order accuracy. These benefits compound over time as systems integrate and operations mature.

Starting the automation journey—even with a focused pilot project—positions your facility for long-term competitiveness. Strategic investment in the right technology transforms operational efficiency from a cost centre into a sustainable advantage.

Explore SmartlogitecX’s warehouse automation solutions to identify where automation can deliver the greatest impact for your operations.

Frequently Asked Questions

1.Is a 30% cost reduction realistic with warehouse automation?

Yes, for many facilities. This figure combines savings from reduced labour costs (20-40%), minimised errors, better space utilisation, and increased productivity. The exact percentage depends on your starting point and the technologies implemented.

2.What is the average return on investment for warehouse automation?

Many businesses achieve payback within 1-3 years, depending on project scope, local labour costs, and the specific technologies chosen.

3.How does automation affect existing warehouse jobs?

While automation reduces manual repetitive tasks, it creates new roles in operations, maintenance, and system management. Many facilities report upskilling their workforce into more technical positions.

4.Can automation be implemented in an existing warehouse?

Yes. “Brownfield” automation using AMRs and collaborative robots integrates into existing layouts with minimal disruption.

5.What is the difference between an AGV and an AMR?

AGVs follow fixed paths using floor-mounted guidance. AMRs navigate dynamically using sensors and mapping to find efficient routes and avoid obstacles.

6.Which industries benefit most from warehouse automation?

E-commerce, retail, third-party logistics, food and beverage, and pharmaceuticals see significant gains due to high order volumes and accuracy requirements.

7.What is the first step to starting an automation project?

Conduct a thorough analysis of current operations to identify significant pain points and bottlenecks. This data-driven approach ensures investment in technology that delivers the best ROI.