Third-party logistics providers face an unprecedented convergence of challenges that threatens operational viability. Warehouse automation has emerged as the definitive response, with industry data revealing that automated systems can reduce labour costs by up to 60% whilst simultaneously improving accuracy and throughput. The surge in e-commerce demand, coupled with persistent labour shortages across Australia, has created a perfect storm that manual operations simply cannot weather. Traditional warehousing methods struggle to deliver the speed and precision that modern supply chain management demands, particularly as client expectations for same-day and next-day delivery intensify. This transformation isn’t merely about installing new equipment; it represents a fundamental reimagining of how 3PL providers approach order fulfilment, inventory control, and resource allocation. As warehouse automation solutions become increasingly sophisticated and accessible, the competitive gap between early adopters and traditional operators widens dramatically. This article examines the specific technologies and strategies that enable third-party logistics providers to achieve measurable efficiency gains whilst positioning their operations for sustainable growth in an increasingly demanding marketplace.

The Core Benefits of Modernising Your Warehouse Operations

The financial and operational advantages of warehouse automation extend far beyond simple labour substitution, creating compound returns that reshape entire business models. Automated systems operate continuously without fatigue, enabling 24/7 productivity cycles that can deliver throughput increases of up to 67% compared to manual operations. These gains manifest across every aspect of warehouse management, from the moment inventory arrives at the receiving dock through to final dispatch. The direct cost savings prove substantial, with reduced reliance on temporary labour during peak periods and dramatically lower error rates that minimise the expensive cascading costs of returns, re-shipments, and client dissatisfaction. SmartlogitecX warehouse solutions demonstrate how intelligent picking systems and dynamic weighing scanning technology can elevate order accuracy to 99% or higher, transforming service quality from a liability into a competitive differentiator. Space optimisation represents another critical ROI driver, as automated storage and retrieval systems exploit vertical dimensions that manual operations cannot efficiently access. This vertical utilisation can recover up to 85% of previously wasted floor space, effectively multiplying capacity within existing facilities and deferring or eliminating the need for costly expansion or additional leasing. Energy efficiency improvements and reduced product damage further contribute to the comprehensive cost reductions that make warehouse automation solutions an essential investment rather than a discretionary upgrade. The cumulative effect of these benefits creates a virtuous cycle where improved efficiency enables better service levels, which in turn supports premium pricing and enhanced client retention.

Key Warehouse Automation Systems for 3PL Success

Understanding the specific technologies available empowers 3PL providers to make informed decisions about their automation journey. Modern warehouse systems encompass several distinct but integrated categories, each addressing particular operational challenges whilst contributing to overall efficiency gains. The landscape of automation technology has evolved rapidly, with solutions now available at various price points and complexity levels to suit operations of different scales and requirements.

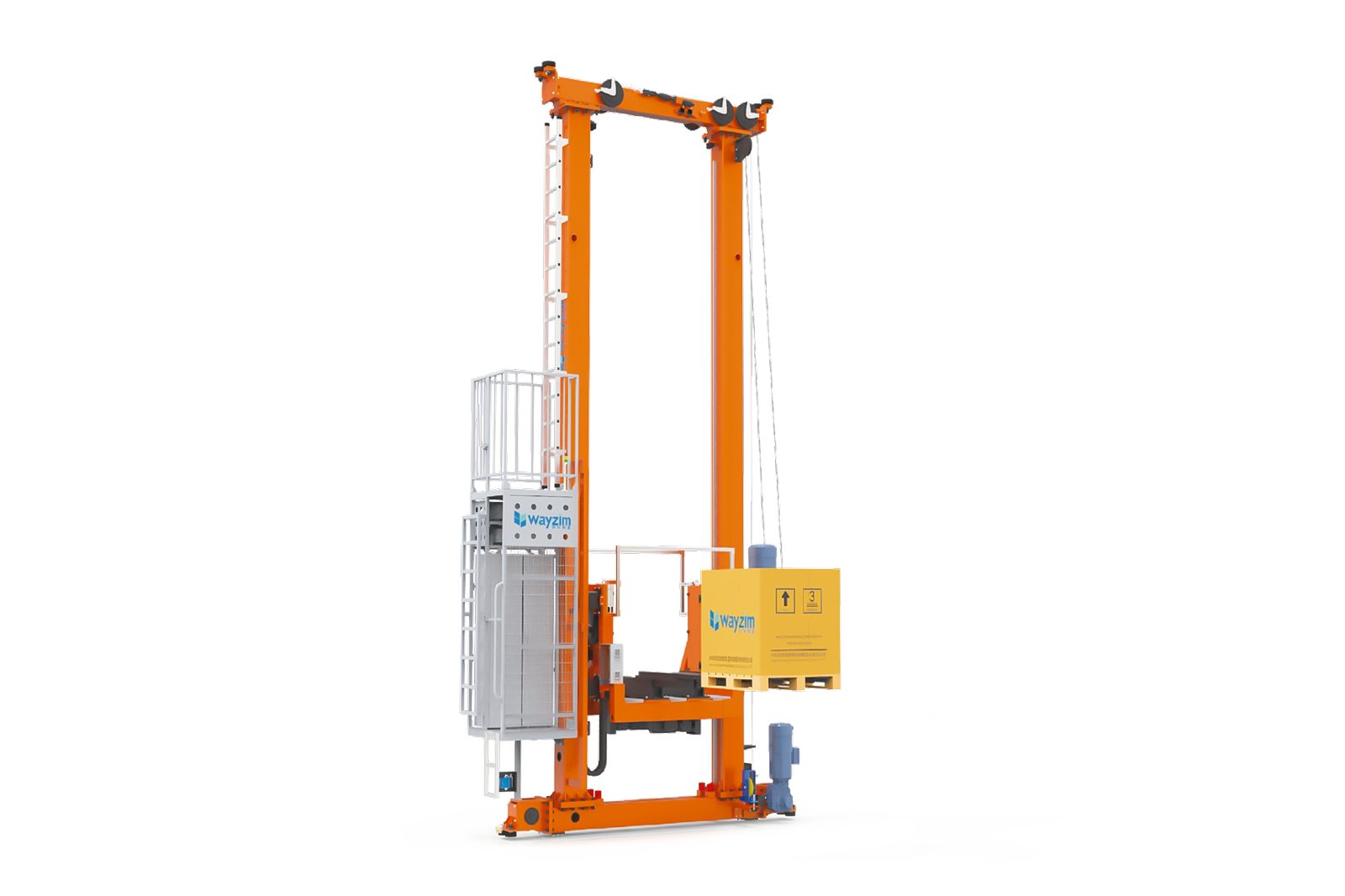

Automated Storage and Retrieval Systems (AS/RS)

Computer-controlled cranes and shuttles form the backbone of AS/RS technology, delivering unmatched precision in high-density storage environments. These systems use sophisticated algorithms to optimise put away locations and retrieval sequences, ensuring that inventory placement supports efficient picking patterns whilst maximising cube utilisation. The automated nature of these systems eliminates the physical limitations that constrain manual storage, allowing facilities to build vertically whilst maintaining rapid access times. SmartlogitecX AS/RS implementations demonstrate how these systems transform traditional racking into dynamic, three-dimensional inventory matrices that respond intelligently to demand patterns and seasonal fluctuations.

Robotics and Autonomous Mobile Robots (AMRs)

The distinction between traditional automated guided vehicles and modern AMRs centers on flexibility and intelligence. Whilst AGVs follow fixed pathways using magnetic strips or wires embedded in floors, AMRs navigate dynamically using onboard sensors and mapping technology. This autonomous capability allows AMRs to adapt to changing warehouse layouts, avoid obstacles, and optimise routing in real-time. Their applications span from transporting goods between zones to collaborative picking operations where they work alongside human staff, eliminating unproductive walking time and allowing workers to focus purely on value-adding selection tasks. The scalability of robotic solutions for logistics automation makes them particularly attractive for growing operations, as additional units can be deployed incrementally to match volume increases.

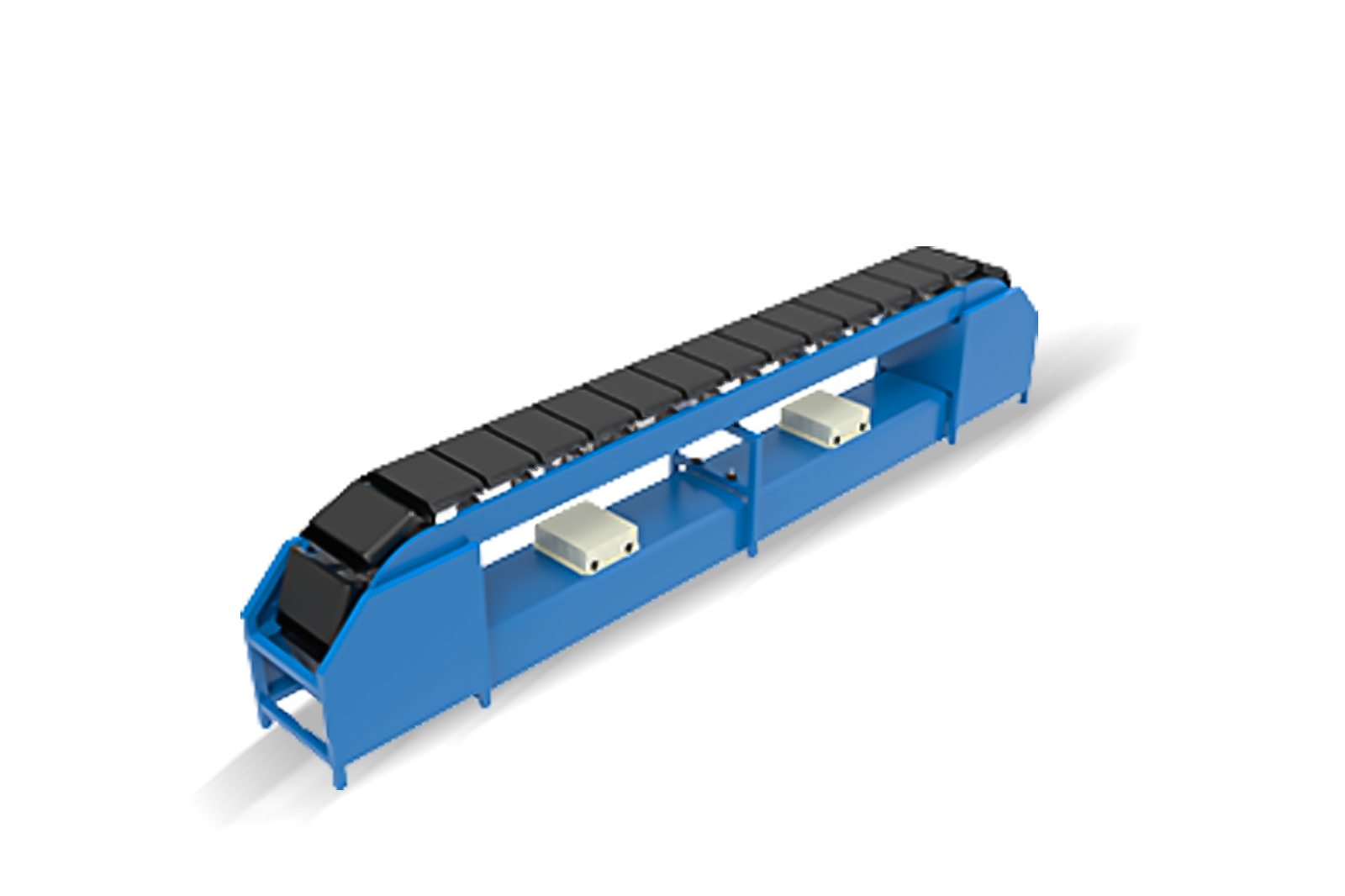

Intelligent Conveyor and Sortation Systems

High-speed movement and sorting represent critical bottlenecks in e-commerce fulfilment operations, where thousands of disparate orders must be processed simultaneously. Linear sorters and pivot wheel sorters handle this complexity through precise mechanical control combined with sophisticated routing logic. These systems can process mixed SKU streams at rates exceeding several thousand items per hour, automatically directing each piece to its designated accumulation lane or packing station. The integration of these sortation systems with upstream picking operations and downstream packing zones creates a continuous flow that eliminates the staging and batching delays inherent in manual processes.

Smart WMS and Vision Technology

The warehouse management system functions as the orchestrating intelligence that coordinates all automated equipment whilst managing inventory data and order workflows. Advanced WMS platforms integrate seamlessly with dynamic dimensioning, weighing, and scanning systems that capture critical shipping data automatically as items move through the facility. SmartlogitecX intelligent vision systems employ line laser stereo cameras and other sophisticated sensing technologies to verify package contents, confirm dimensions and weights, and ensure shipping label accuracy without human intervention. This elimination of manual data entry removes a major source of errors whilst accelerating throughput and enabling real-time visibility into operational performance.

Practical Applications Driving 3PL Efficiency

The true measure of automation technology lies in its practical impact on daily warehouse operations and its ability to solve persistent logistical challenges. E-commerce fulfilment demands have fundamentally altered the operational requirements for 3PL providers, with businesses now managing SKU counts in the tens of thousands whilst meeting customer expectations for rapid delivery. Goods-to-person systems address this complexity by bringing inventory to stationary picking stations, where workers can process orders at rates several times faster than traditional pick-to-cart methods. High-speed sorters then consolidate these picked items into individual orders, automatically routing them to appropriate packing stations based on shipping method and destination. Inventory management achieves unprecedented accuracy when RFID technology, integrated WMS platforms, and robotic systems combine to provide real-time visibility into stock locations and quantities. This precision eliminates the discrepancies that plague manual inventory systems, reducing stock outs and overstock situations whilst enabling continuous cycle counting that maintains data integrity without disruptive physical inventories. The flow of goods through receiving, put away, picking, packing, and shipping becomes fluid and predictable when automation orchestrates each transition, with data captured automatically at each stage to provide complete traceability. These practical applications demonstrate how warehouse automation solutions transform theoretical efficiency gains into measurable improvements in order accuracy, throughput, and client satisfaction.

Important Factors for a Successful Implementation

Deploying warehouse automation requires strategic planning and realistic assessment of both opportunities and challenges. The initial investment demands careful financial analysis, with business cases built on concrete projections of labour savings, error reduction, and throughput improvements rather than aspirational estimates. Whilst upfront costs can be substantial, particularly for comprehensive AS/RS installations or fleet-scale robotic deployments, the long-term returns typically deliver payback periods of two to three years for well-planned implementations. System integration presents technical challenges that require expertise, as new automation equipment must communicate effectively with existing WMS, ERP, and transport management systems. SmartlogitecX works closely with clients to ensure seamless data exchange and coordinated operation across all warehouse systems, avoiding the operational disruptions that can occur when technologies clash. The human dimension of automation implementation often receives insufficient attention, yet change management and workforce upskilling determine whether new systems achieve their potential or generate resistance and underutilisation. Transparent communication about how automation will reshape job roles, combined with comprehensive training programmed that prepare staff for supervisory and maintenance responsibilities, transforms potential opposition into engaged partnership. Selecting the right technology partner proves equally critical, as experienced warehouse automation companies bring not only equipment but also process expertise, integration capabilities, and ongoing support that ensures systems continue to deliver value as operational requirements evolve.

Future-Proofing Your 3PL Business

Warehouse automation has transitioned from competitive advantage to operational necessity for 3PL providers seeking sustainable success in modern supply chains. The evidence is compelling: enhanced efficiency, reduced operational costs, superior accuracy, and improved client satisfaction create a foundation for growth that manual operations cannot replicate. Australian logistics providers face unique challenges with geographic distances and evolving e-commerce expectations, making automation investments particularly strategic for maintaining competitiveness. The question has shifted from whether to automate to how quickly and comprehensively organisations can transform their operations. Beginning this journey requires honest assessment of current processes, identification of specific bottlenecks and inefficiencies, and clear articulation of business objectives that automation must serve. The technologies exist, the business case is proven, and the operational imperative is clear. Forward-thinking 3PL providers will recognise that investing in warehouse automation solutions today determines their market position tomorrow.

Frequently Asked Questions

1.What is the typical return on investment for warehouse automation?

Most 3PL providers achieve positive ROI within two to three years following implementation. The returns derive primarily from substantial labour cost savings, increased throughput capacity, and dramatic reductions in costly errors. Facilities processing higher volumes typically see faster payback periods, whilst the cumulative benefits continue to compound well beyond the initial return threshold.

2.How does automation affect labour requirements in a warehouse?

Automation fundamentally reshapes rather than eliminates labour requirements. The technology shifts workers from repetitive manual tasks such as walking long distances and heavy lifting towards higher-value roles including system oversight, equipment maintenance, quality control, and exception handling. This transition addresses labour shortage challenges whilst creating more engaging and sustainable employment opportunities.

3.Can automated systems be integrated with our existing WMS?

Modern warehouse automation solutions are specifically engineered for integration with existing technology infrastructure. Leading providers ensure their equipment can communicate seamlessly with established warehouse management systems and ERP platforms through standard protocols and APIs. Integration planning forms a critical component of any implementation project to ensure unified operation across all systems.

4.How does automated sorting improve delivery times?

Automated sortation systems process thousands of items per hour with extreme precision, dramatically compressing the time required to segregate mixed inventory into individual orders ready for dispatch. This acceleration in the sortation phase eliminates a major bottleneck in the fulfilment cycle, enabling faster order-to-ship times and supporting aggressive delivery commitments.

5.What are the first steps to implementing warehouse technology?

Implementation begins with comprehensive operational assessment to identify specific bottlenecks, inefficiencies, and improvement opportunities. Following this analysis, organisations should establish clear performance objectives, develop detailed ROI projections, and engage experienced automation providers to design tailored solutions. Pilot programmed or phased implementations can reduce risk whilst building organisational capability.

6.How can automation reduce errors in storage and retrieval?

AS/RS and robotic systems employ computer-guided precision for both put away and picking operations, virtually eliminating the human errors that cause misplaced inventory and incorrect selections. Barcode verification, weight confirmation, and vision systems provide multiple validation checkpoints that ensure accuracy throughout the handling process.

7.What kind of productivity increase can be expected from automated warehousing?

Productivity gains typically range from 200% to 300% compared to manual operations, though specific results vary based on implementation scope and existing efficiency levels. The improvements stem from eliminating non-value-adding activities such as travel time, reducing handling touches, and enabling workers to focus exclusively on productive tasks.

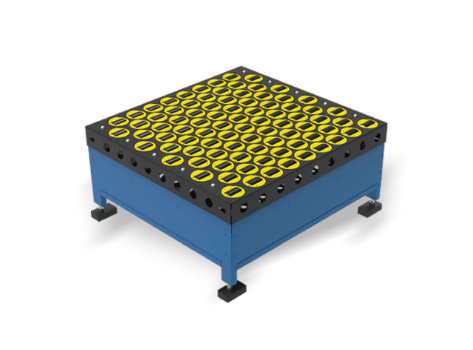

8.How does technology help optimise warehouse space?

Automated storage and retrieval systems exploit vertical dimensions far more effectively than manual operations, often achieving storage densities three to four times greater within identical footprints. This multiplication of effective capacity can defer or eliminate facility expansion requirements, generating substantial savings in construction costs and ongoing premises expenses.

9.Are automated systems scalable for a growing 3PL?

Scalability represents a fundamental design principle for modern automation, particularly solutions based on autonomous mobile robots. Organisations can begin with modest deployments and systematically expand capacity by adding additional robots or modules as order volumes increase, avoiding the oversizing and underutilisation risks associated with fixed infrastructure investments.

10.What are the main types of robotic solutions used in logistics?

Contemporary logistics operations employ several robotic categories including autonomous mobile robots for goods transport, articulated robotic arms for picking and packing applications, automated guided vehicles for structured movement tasks, and collaborative robots designed for safe human interaction. Each category addresses specific operational requirements whilst contributing to overall system efficiency.