The customer is a leading automaker in China. The parts warehousing management efficiency of its R&D centre has a direct impact on the R&D progress and testing continuity of new vehicle models. Due to low space utilisation, high manual error rate, and slow response, conventional warehousing methods cannot meet modern automakers’ requirements for frequent inbounds/outbounds, a massive number of SKUs, and small batches.

Wayzim is a leading integrator of intelligent logistics equipment and systems. Leveraging its strong R&D capabilities and rich industry experience, the company provides a tailor-made SmartlogitecX Automated Storage and Retrieval System (AR/RS), featuring high storage density, efficient operations, and intelligent scheduling, for the customer. This project is not only Wayzim’s another benchmark work for the high-end manufacturing industry, but also an all-round demonstration of the company’s integrated software and hardware strength. It provides a replicable, proven model for intelligent warehousing system upgrades in the automobile R&D field.

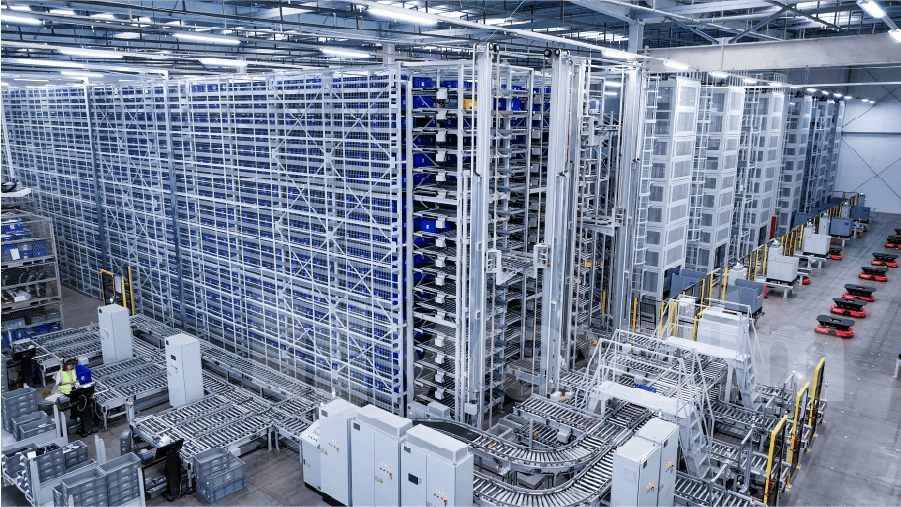

This project occupies an area of around 4,300 m2. To meet the customer’s requirements for high space utilisation, operation efficiency, and management precision, Wayzim provides an intelligent warehousing system that can handle both totes and pallets.

The system consists of a tote AS/RS, a pallet AS/RS, a conveyor system, a SmartlogitecX AMR system, and an intelligent picking system. It enables automated and digital management of the entire warehousing process from inbound, storage, and picking to outbound.

Pain Points

Solution

Wayzim builds a tote AS/RS and a pallet AS/RS to help the customer manage small and large items at the same time.

The tote AS/RS is mainly used for automated storage and picking of small items. Using high-speed (up to 5 m/s) two-way shuttles, this system enables frequent tote handling at a high speed. The AMRs automatically transport totes to the inbound docks, where the conveyor lines receive the totes and send them to the AS/RS. During outbound operations, the system automatically transports totes to the picking stations through task scheduling and returns devices to their original positions after the operation is completed to close the loop of unmanned storage and retrieval.

The pallet AS/RS handles centralised storage and management of large items. With independent X-axis and Y-axis wheels, the pallet four-way shuttles can move flexibly in narrow aisles and work with the pop-up mechanism and vertical conveyors to handle pallets on different levels. The multi-level shelf system fully utilises the vertical space, greatly improving the storage density.

As the key equipment for ground operations, the AMRs transfer materials between different areas during material flow in the warehouse. The picking personnel can complete operations without leaving their workstations, which significantly improves picking efficiency.

Space Utilisation Up by Over 50%

The multi-level shelf system (17 levels for the tote AS/RS and 5 levels for the pallet AS/RS) utilises the vertical space, doubling the storage capacity with the same floor area.

Goods-to-Person Picking

The picking operators can stay at ergonomic workstations and wait for the system to deliver the required totes and pallets. This mode multiplies the picking efficiency and reduces operators’ physical effort. More importantly, it enables people to focus on more valuable tasks, such as verification and error handling, achieving the optimal human-machine collaboration.

Precise and Efficient Digital Operations

Wayzim’s WMS and WCS* systems enable visualised inventory management and task scheduling in real time, which allows intelligent task allocation and efficient execution, minimises human involvement, and improves the overall operational transparency and response speed.

Warehouse Management System (WMS) and Warehouse Control System (WCS)

Safety Compliance and Human-oriented Design

An emergency access, the first of its kind, is provided in the multi-level shelf system with four-way shuttles to ensure that the areas around fire hydrants can be accessed quickly and safely during emergencies.

Summary

With forward-looking system planning, advanced equipment technology, and intelligent software platforms, Wayzim’s solutions address the warehousing challenges for high-end manufacturing enterprises and yield remarkable economic and management benefits. This case demonstrates Wayzim’s strengths in providing top-level design, system integration, and continuous services for world-class customers. It highlights its role as a cornerstone enabler for smart logistics in China’s transformation from a major manufacturing country to a strong manufacturing country.