Introduction to Warehouse Automation

In an age where efficiency and speed are the cornerstones of successful logistics, warehouse automation emerges as a game-changer. This technological marvel represents more than just an upgrade to traditional warehousing methods; it’s a complete overhaul, reinventing how businesses handle inventory, fulfill orders, and manage supply chains. Warehouse automation leverages cutting-edge technologies such as robotics, artificial intelligence (AI), and sophisticated software systems to streamline operations, minimise human error, and optimise storage solutions.

The inception of warehouse automation marked a pivotal moment in the history of logistics and supply chain management. It promised a future where machines and software systems work in tandem to create a more efficient, accurate, and safe environment. From robotic arms that deftly sort and package goods to autonomous vehicles that transport items across vast warehouse spaces, the possibilities seem boundless.

Moreover, the integration of AI has enabled predictive analytics and real-time decision-making, ensuring a more responsive and adaptable warehousing operation. But what does all this mean for the industry as a whole? Warehouse automation is not merely about replacing manual labor with machines; it’s about creating a symbiotic ecosystem where human intelligence and machine precision coexist. It’s about leveraging technology to amplify efficiency and accuracy, thereby transforming the very fabric of supply chains across the globe.

As businesses continue to grapple with increasing consumer demands and the relentless pace of the digital world, warehouse automation stands as a beacon of innovation and efficiency. In the following sections, we’ll dive deeper into the technological advancements driving this revolution, explore the myriad benefits, address the challenges faced in adopting such technologies, and gaze into the crystal ball to predict future trends in warehouse automation.

Technological Advances in Warehouse Automation

The landscape of warehouse automation is constantly evolving, driven by rapid technological advances. These innovations are not just enhancing existing systems but are also paving the way for entirely new methods of managing warehouse operations.

- Robotics

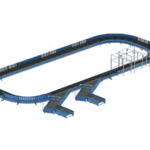

The Backbone of Modern Warehouses Robotic technology has become the backbone of modern warehouse automation. Robotic arms, for instance, are now more sophisticated than ever, capable of performing a wide range of tasks from picking and packing to sorting and assembly. These robots can work tirelessly, increase throughput, and reduce the likelihood of errors that can occur with manual handling. - Artificial Intelligence and Machine Learning

AI and machine learning are at the forefront of transforming warehouse operations. These technologies enable predictive analytics, which can forecast inventory needs, optimise stock levels, and anticipate order trends. AI algorithms can also make real-time decisions on the best routes for goods to travel within the warehouse or the most efficient way to organise inventory. - Internet of Things (IoT)

Integration The Internet of Things (IoT) plays a crucial role in warehouse automation by enabling a network of interconnected devices. Sensors and RFID tags are extensively used to track inventory in real-time, providing visibility into every aspect of the warehouse operation. This connectivity not only enhances inventory management but also improves the accuracy of order fulfillment and reduces the risk of stockouts. - Advanced Software Systems

The integration of advanced software systems is a key component of warehouse automation. Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) systems are becoming more sophisticated, offering features like real-time data analytics, labor management, and automated order processing. These systems help in streamlining operations, improving order accuracy, and reducing processing times. - Drones for Inventory Management

Drones are emerging as a valuable tool in warehouse management. Equipped with cameras and sensors, drones can perform inventory checks rapidly, reaching areas that are challenging for humans or ground-based robots. This technology not only speeds up inventory checks but also reduces the risks associated with manual stocktaking.

Benefits of Implementing Warehouse Automation

Warehouse automation has rapidly transformed into a cornerstone of modern logistics and supply chain management, offering a plethora of benefits that extend far beyond mere efficiency. This segment delves into the key advantages that warehouse automation brings to businesses.

- Enhanced Efficiency and Productivity

The most immediate benefit of warehouse automation is the significant boost in efficiency and productivity. Automated systems and robots can operate around the clock, drastically reducing the time taken to perform tasks like picking, packing, and sorting. This relentless pace ensures that orders are processed faster, ultimately leading to quicker delivery times and enhanced customer satisfaction. - Cost Savings in the Long Run

While the initial investment in warehouse automation might be substantial, the long-term cost savings are considerable. Automated systems reduce the need for extensive manual labor, thereby lowering labor costs. Additionally, these systems minimise errors and damages associated with manual handling, further cutting down on operational expenses. - Improved Accuracy and Reliability

Automation significantly enhances the accuracy of various warehouse operations. Automated systems are programmed to follow precise instructions, ensuring that tasks such as inventory tracking, order picking, and packaging are carried out with minimal errors. This accuracy bolsters reliability in the supply chain, leading to fewer returns and higher customer trust. - Safety Enhancements

Warehouse automation also plays a pivotal role in enhancing worker safety. By automating potentially hazardous tasks, the likelihood of accidents and injuries in the workplace is greatly reduced. Robots and automated machinery can handle heavy lifting and repetitive tasks, thereby minimising the physical strain on human workers. - Scalability and Flexibility

Automated warehouse systems offer the flexibility to scale operations up or down based on demand. During peak seasons, these systems can easily handle increased workloads without the need for additional human resources. This scalability ensures that businesses can adapt to market changes and consumer demands efficiently. - Data-Driven Insights and Optimisation

Lastly, warehouse automation provides valuable data-driven insights. Automated systems continuously collect data on various operations, allowing businesses to analyse and optimise their processes. This analysis leads to better decision-making, enhanced forecasting, and continuous improvement in operations.

Challenges and Considerations in Adopting Warehouse Automation

While the benefits of warehouse automation are clear, its implementation is not without challenges. Businesses must navigate a range of considerations to ensure successful integration of these technologies. This section outlines key challenges and strategic factors to consider.

- High Initial Investment

One of the primary challenges is the substantial initial investment required for automation technology. Installing robotic systems, AI, and advanced software can be costly. Companies need to evaluate their financial capability and plan for a return on investment over time. Securing funding and managing budget constraints are crucial steps in this process. - Integration with Existing Systems

Integrating new automation technology with existing warehouse infrastructure and systems can be complex. Businesses must ensure compatibility between new and old systems, requiring careful planning and potentially significant adjustments to current processes. - Skilled Labor for Operation and Maintenance

While automation reduces the need for manual labor, it simultaneously demands skilled professionals to operate and maintain these sophisticated systems. Finding and training staff with the necessary technical expertise is a critical aspect of successful automation. - Dependence on Technology and Risk of Failures

An increased reliance on technology comes with its own set of risks, including system failures and cyber threats. Companies must have robust contingency plans and security measures in place to mitigate these risks and ensure continuous operation. - Change Management and Employee

Pushback Implementing warehouse automation involves significant changes in workplace dynamics. This can lead to resistance from employees, who might fear job loss or the need to adapt to new roles. Effective change management strategies are essential to address these concerns and ensure a smooth transition. - Keeping Pace with Technological Advancements

Finally, technology evolves rapidly. Companies need to stay informed about the latest developments in automation to maintain a competitive edge. This involves ongoing investment in upgrades and training to keep up with technological advancements.

Future Trends and Predictions in Warehouse Automation

As we stand at the forefront of a rapidly evolving technological landscape, warehouse automation is set to undergo even more revolutionary changes. This section explores the emerging trends and predictions that are likely to shape the future of warehouse operations.

Increased Adoption of AI and Machine Learning

Artificial intelligence and machine learning will continue to be at the heart of warehouse automation. We can expect these technologies to become more sophisticated, enabling even more efficient inventory management, predictive maintenance, and decision-making processes.

Advanced Robotics and Cobots

The next generation of robots will be more advanced, with enhanced capabilities and flexibility. Collaborative robots, or ‘cobots’, designed to work alongside humans, will become more prevalent. These cobots will augment human abilities rather than replace them, leading to more efficient and harmonious workflows.

Greater Integration of IoT and Real-Time Analytics

The Internet of Things (IoT) will see a broader application in warehouses. The integration of more sensors and smart devices will provide real-time analytics and insights, leading to more responsive and adaptive warehouse operations.

Expansion of Autonomous Vehicles and Drones

Autonomous vehicles and drones will become more common for tasks like transportation, delivery, and inventory management within warehouses. Their use will streamline operations, reduce manual labor, and increase speed and efficiency.

Emphasis on Sustainability and Energy Efficiency

Sustainability will become a key focus area. Warehouse automation will increasingly incorporate green technologies, aiming for energy-efficient operations and reduced carbon footprints. This shift will not only benefit the environment but also align with the growing consumer demand for sustainable business practices.

Customisation and Personalisation through Automation

Finally, warehouse automation will enable higher levels of customisation and personalisation in order processing and logistics. Automated systems will be able to handle unique customer requests with greater precision, contributing to enhanced customer satisfaction and loyalty.

Embracing the Future of Warehouse Automation

As we have explored throughout this article, warehouse automation represents a transformative shift in the logistics and supply chain industry. From the integration of advanced robotics and AI to the application of IoT and sustainable practices, this revolution is not just about enhancing efficiency and productivity, it’s about redefining how businesses approach inventory management and order fulfillment.

The journey towards fully automated warehouses is fraught with challenges, including substantial initial investments, integration complexities, and the need for skilled personnel. However, the long-term benefits increased efficiency, cost savings, improved accuracy, and enhanced safety make it a compelling proposition for any forward-thinking business.

Looking ahead, the landscape of warehouse automation is poised for even more groundbreaking innovations. The continued evolution of AI, the adoption of cobots, advancements in autonomous vehicles and drones, and a stronger focus on sustainability are just a few of the trends that will shape the future of this field.

As technology continues to advance, warehouse automation will become not just a luxury but a necessity for businesses seeking to remain competitive in a rapidly changing world. Warehouse automation is much more than a technological upgrade, it’s a strategic imperative in today’s digital era. By embracing these innovations, businesses can not only optimise their operations but also prepare themselves for the demands of the future.

The era of warehouse automation is here, and it is redefining the boundaries of what is possible in logistics and supply chain management. SmartlogitecX, empowered by WayZim Technologies, is at the forefront of revolutionising Warehouse Automation in the Australian and New Zealand market. Be part of the logistics transformation.

Embrace SmartlogitecX’s locally-focused, globally-backed expertise. Redefine your operations, harnessing the power of technology made for Australia and New Zealand.

Ready to elevate your logistics? Reach out SmartlogitecX sales team for your customised automation solution.