Introduction: Addressing the Labour Challenge

The logistics and warehousing industries are facing an unprecedented crisis. With labour shortages reaching critical levels across the globe, businesses are struggling to maintain operational efficiency while meeting growing customer demands. In fact, 60% of warehouse operators report difficulty finding and retaining qualified workers, leading to delayed shipments, increased costs, and compromised customer satisfaction.

Enter SmartlogitecX warehouse automation—a transformative solution that’s rapidly becoming essential rather than optional. By integrating intelligent machines, robotics, and sophisticated software systems, warehouse automation reduces dependency on manual labour while dramatically improving speed, accuracy, and overall productivity. This technology isn’t just about replacing workers; it’s about empowering your existing workforce to focus on higher-value tasks while machines handle repetitive, physically demanding operations.

Understanding Warehouse Automation Technologies

Modern warehouse automation encompasses a diverse ecosystem of interconnected technologies designed to streamline every aspect of warehouse operations. These automated warehouse systems work in harmony to create facilities that can operate with minimal human intervention, maximum efficiency, and unprecedented accuracy.

The foundation of warehouse automation technologies lies in their ability to integrate seamlessly, creating a synchronised operation where data flows freely between systems, equipment responds intelligently to changing demands, and productivity soars beyond traditional manual capabilities.

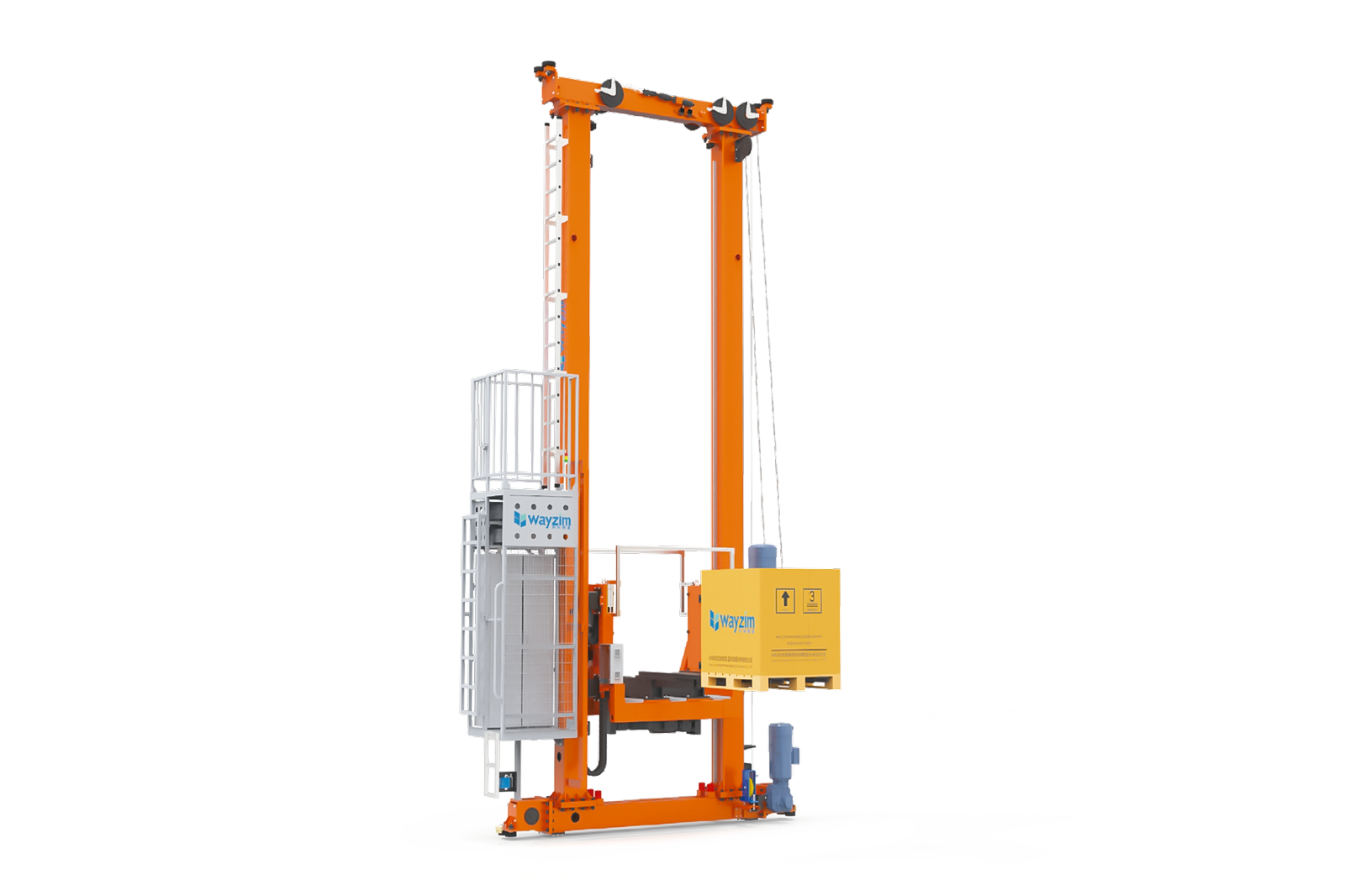

Automated Storage and Retrieval Systems (AS/RS)

At the heart of many automated facilities lies the SmartlogitecX automated storage and retrieval system (AS/RS), a game-changing technology that revolutionises how goods are stored and accessed. These systems maximise vertical space utilisation while providing lightning-fast retrieval times that manual operations simply cannot match.

AS/RS warehouse implementations come in various configurations to suit different operational needs:

- Unit-load AS/RS: Ideal for handling full pallets and large containers

- Mini-load systems: Perfect for smaller items and case handling

- Shuttle systems: Offering flexible, high-density storage with rapid throughput

- Carousel systems: Providing ergonomic picking solutions for smaller parts

The automated pallet storage and retrieval system represents one of the most impactful implementations, capable of managing thousands of pallets in a fraction of the space required by traditional racking.

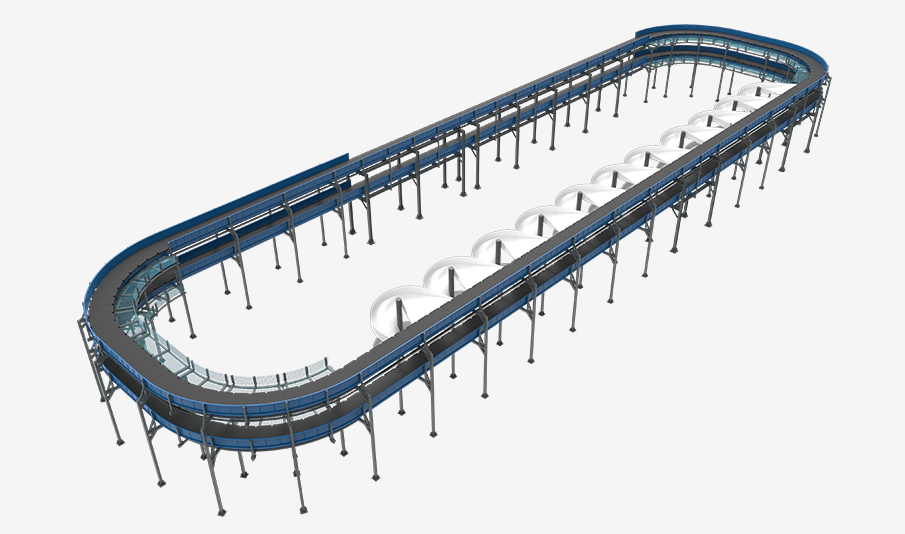

The Rise of Warehouse Robotics

Warehouse robotics has evolved from science fiction to operational reality, fundamentally changing how goods move through distribution centres. Today’s robotic solutions include Autonomous Mobile Robots (AMRs) that navigate freely using sophisticated sensors, Automated Guided Vehicles (AGVs) that follow predetermined paths, and robotic arms that can pick items with human-like dexterity.

Automated picking systems now handle millions of orders daily across global warehouses. These robots work tirelessly 24/7, maintaining consistent speed and accuracy that human workers struggle to match over extended periods. The implementation of automated warehouse picking has shown productivity improvements of, 50% while virtually eliminating picking errors that plague manual operations.

Optimising Operations with Advanced Control Systems

While physical automation captures attention, the software orchestrating these systems represents the true intelligence behind modern warehouse automation. These digital brains ensure every component works in perfect harmony, optimising workflows in real-time.

Warehouse Control Systems and Execution Systems

Understanding the distinction between warehouse control systems and warehouse execution systems is crucial for successful automation implementation. The Warehouse Control System (WCS) acts as the tactical commander, directly controlling equipment like conveyors, sorters, and AS/RS units. It makes split-second decisions about routing, sequencing, and equipment optimisation.

Meanwhile, the warehouse execution system (WES) operates at a higher strategic level, orchestrating overall warehouse operations by coordinating between the WCS, Warehouse Management System (WMS), and Enterprise Resource Planning (ERP) systems. The WES optimises order fulfilment strategies, manages resource allocation, and ensures smooth workflow across all automated and manual processes.

Together, these systems create an intelligent ecosystem that adapts to changing conditions, prioritises urgent orders, and maximises throughput while minimising energy consumption and equipment wear.

Benefits of Embracing Warehouse Automation Solutions

Solving Labour Shortages and Boosting Productivity

Warehouse automation solutions directly address the labour crisis by fundamentally changing operational requirements. Instead of needing dozens of workers for picking, packing, and moving inventory, automated systems can handle these tasks with minimal human oversight. This doesn’t eliminate jobs—it transforms them, creating opportunities for workers to manage technology, handle exceptions, and focus on customer service.

Enhanced Accuracy, Safety, and Scalability

Beyond addressing labour shortages, automation delivers multiple operational advantages. Error rates plummet when machines handle repetitive tasks, with some automated systems achieving accuracy rates exceeding 99.9%. This precision translates directly to improved customer satisfaction and reduced returns.

Safety improvements are equally impressive. Automated systems eliminate many workplace hazards, from forklift accidents to repetitive strain injuries. Workers no longer need to climb ladders, lift heavy items, or navigate congested warehouse aisles.

Perhaps most importantly, automation provides unprecedented scalability. During peak seasons or sudden demand spikes, automated systems can increase throughput without the hiring challenges, training time, and costs associated with temporary labour.

Choosing Your Warehouse Automation Partner

Leading Warehouse Automation and Robotics Companies

Selecting among warehouse automation companies requires careful evaluation of capabilities, experience, and support infrastructure. Leading warehouse robotics companies offer comprehensive solutions, from initial consultation through implementation and ongoing maintenance.

Industry leaders like Swisslog AutoStore exemplify the innovation driving this sector, offering cube storage systems that maximise space efficiency while providing rapid access to inventory. When evaluating potential partners, consider these critical factors:

Key Evaluation Criteria:

- Industry experience and proven implementations

- Integration capabilities with existing systems

- Scalability of proposed solutions

- Training and support programs

- Total cost of ownership and ROI projections

- Technology roadmap and innovation commitment

The right partner will offer not just technology, but a collaborative approach to solving your specific operational challenges while preparing your facility for future growth.

Moving Forward with Warehouse Automation

The question isn’t whether to implement warehouse automation, but how quickly you can begin the transformation. As labour shortages persist and customer expectations continue rising, automated warehouses will increasingly separate market leaders from those struggling to compete.

Start your automation journey by assessing your current pain points, whether they’re labour availability, accuracy issues, or capacity constraints. Even incremental automation implementations can deliver immediate benefits while building toward a fully automated future.

Are you ready to transform your warehouse operations and solve your labour challenges through strategic automation implementation?