Package delivery services are essential to our modern economy. As online shopping continues to grow, the number of packages being shipped is increasing exponentially. This puts immense pressure on delivery companies to sort parcels quickly and efficiently. Automated parcel sorting systems provide a high-tech solution to this challenge.

What are Automated Parcel Sorting Systems?

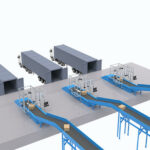

Automated parcel sorting systems are complex pieces of machinery that rapidly sort packages using advanced technology. These systems utilise a combination of scanners, sensors, conveyor belts, chutes, and robotic arms to direct packages to their proper destination.

Instead of relying on human workers to manually read labels and sort boxes, automated systems can process hundreds or even thousands of parcels per hour with minimal human involvement. This results in faster processing times and reduced labor costs.

Automated sorting systems are highly customisable with variable speeds, dimensioning capabilities, and sorting destinations. This allows them to be tailored to the specific needs of the logistics company. Larger systems even utilise artificial intelligence to optimise the sorting process.

Benefits of Automated Parcel Sorting

There are many advantages to implementing automated parcel sorting systems:

1. Increased Throughput and Efficiency

Automated systems significantly increase the number of packages that can be processed per hour. While a human may be able to manually sort a few hundred packages per shift, an automated system can blast through thousands without breaking a sweat. This results in faster delivery times and improved workflow efficiency.

2. Lower Operating Costs

By reducing reliance on manual labor, automated sorting systems lower a company’s operating costs. The systems have a high upfront investment but pay for themselves over time by cutting payroll expenses. HR management and turnover costs are also minimised.

3. Smaller Footprint

Automated systems take up much less space than traditional manual sorting operations. Their compact footprint results in reduced facility costs and the ability to operate in urban areas.

Increased accuracy makes mistakes, but machines don’t. Parcel sorting automation virtually eliminates errors in the sorting process. Packages are directed to the correct destination every time. This prevents losses and delivery delays.

4. 24/7 Operation

Automated systems can operate around the clock with minimal downtime. Day and night parcel sorting capabilities allow logistics companies to keep up with consumer demand at all hours.

How do Automated Parcel Sorting Systems work?

The step-by-step process varies between systems, but generally:

Packages are loaded onto a conveyor belt or feeder system, either manually or automatically.

Identification scanners read package labels to collect crucial information like addresses, tracking numbers, dimensions, and weight.

The scanning data is sent to the sorting system’s computer software which utilises special algorithms to determine the optimal sorting destination for each package.

Conveyors transport the packages into the sorting area where robotic arms pick them up and move them into chutes leading to their designated sort locations.

Sorted packages slide down the chutes into cages, bags, or containers which will be transported to trucks or aircraft for delivery.

Throughout this automated process, the system tracks and logs each package to maintain the chain of custody and provide real-time tracking data. Diagnostic systems monitor for errors or blockages that require human intervention to resolve.

The Future of Delivery Sortation

As eCommerce grows exponentially, the parcel sorting demands placed on logistics companies will continue to increase. Automated sorting systems provide the speed, accuracy, and reliability needed to keep up.

Implementing these advanced robotic solutions requires a significant upfront investment. However, the long-term payoff from improved efficiency and lower labor costs makes them extremely financially viable.

Automated parcel sorting paves the way for the future of delivery by enabling companies to handle growing package volumes while providing consumers with fast, accurate deliveries. The technology will only continue to advance using AI and robotics. Logistics companies that embrace warehouse automation will have a competitive edge in the world of eCommerce fulfillment.

Empower your logistics with SmartlogitecX, fueled by WayZim Technologies. As leaders in Warehouse Automation for the Australian market, we’re dedicated to delivering efficiency and innovation right to your doorstep. SmartlogitecX’s approach is two-fold: globally informed and locally applied. Take the first step towards optimised operations by reaching out to our sales team for a solution that speaks directly to your needs.

Frequently Asked Questions About Automated Parcel Sorting

Q: How fast can automated parcel sorting systems work?

A: High-speed systems can sort over 15,000 parcels per hour. The fastest systems have throughput exceeding 30,000 packages per hour.

Q: What sizes of parcels can automated systems handle?

A: Many systems can sort packages ranging in size from document envelopes to large boxes weighing up to around 50 pounds. Dimensioning technology can measure and accommodate various shapes and sizes.

Q: Can the systems read all types of package labels?

A: Advanced scanning technology can read linear barcodes, 2D codes, addresses, and QR codes. Some systems can even capture information from handwritten labels.

Q: How accurate is the sorting process?

A: Automated systems typically have sorting accuracy between 99.9% and 99.995%. This extremely high accuracy minimises costly delivery errors.

Q: Do they require a large facility?

A: Compact systems are designed to fit in facilities as small as 4,000 square feet. However, optimal operation requires adequately sized buildings to accommodate conveyors and chutes.