In today’s fast-paced world, businesses across industries are constantly seeking ways to streamline operations, boost efficiency, and optimise workflow. One area where innovation is rapidly transforming and driving tangible results is in material handling—enter the age of automated conveyor systems.

From Manual Labor to Intelligent Machines

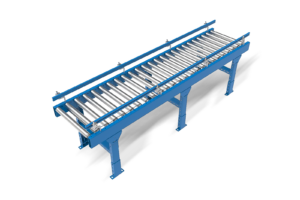

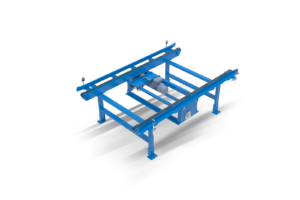

Traditional conveyor systems, while effective, rely heavily on manual oversight and intervention. This can lead to inefficiencies, human error, and limitations in adaptability. Automated conveyor systems, however, are rewriting the rules. Leveraging sophisticated technologies like artificial intelligence (AI), machine learning, and advanced sensors, these intelligent machines take the reins, independently managing material flow with remarkable precision and speed.

The Powerhouse of Automation

Several key technologies power the impressive capabilities of automated conveyor systems.

- AI and Machine Learning: The brains of the operation, AI algorithms analyse real-time data from sensors to intelligently plan and execute transport routes, dynamically adapting to changes in production or workflow. This dynamic routing minimises stoppages and optimises material flow, maximising efficiency.

- Sensor Network: A constant flow of data feeds the decision-making process. Optical, pressure, and barcode scanners provide the system with crucial information about package dimensions, weight, destination, and even potential obstructions. This real-time awareness allows for precise sorting, diversion, and tracking.

- Actuators: The muscles of the system, actuators like servo motors and pneumatic cylinders translate the commands from the central controller into physical movement. They control belts, diverters, and other mechanisms, ensuring smooth and accurate material movement.

- Programmable Logic Controllers (PLCs): The central nervous system, PLCs analyse sensor data, interpret AI commands, and issue instructions to actuators. They orchestrate the entire operation, ensuring everything runs smoothly and efficiently.

Benefits Beyond Imagination

The advantages of adopting automated conveyor systems are numerous and undeniable.

- Surging Efficiency: By eliminating manual intervention and optimising routes through AI, automated systems significantly reduce bottlenecks and speed up material flow. This translates to increased throughput, faster production cycles, and improved on-time delivery.

- Cost Optimisation: Lower staffing requirements due to reduced reliance on human operators translate to significant cost savings. Additionally, efficient material handling and optimised routes minimise energy consumption, further reducing operational expenses.

- Accuracy Unmatched: Automated systems rely on precise sensors and intelligent algorithms, virtually eliminating human error in sorting and routing. This leads to fewer misplaced packages, reduced damage, and improved product quality.

- Enhanced Safety: With humans removed from the immediate vicinity of moving conveyors, the risk of workplace accidents diminishes dramatically. Safety sensors further protect personnel and equipment by stopping operations in case of obstructions.

- Real-Time Transparency: Comprehensive data collection and tracking provide valuable insights into material location, inventory levels, and overall system performance. This real-time visibility empowers better decision-making and facilitates continuous improvement.

- Scalability and Flexibility: Unlike their rigid predecessors, automated systems are inherently flexible. Conveyor lines and diverters can be readily added, removed, or reconfigured to adapt to changing production volumes, product types, or facility layouts.

Applications Spanning Industries

The versatility of automated conveyor systems makes them invaluable across various industries.

- Warehousing and Distribution: From streamlined putaway and sorting to rapid order fulfillment, automated systems transform warehouse operations, boosting productivity and improving customer satisfaction.

- Manufacturing: Automated material handling within production lines ensures seamless delivery of parts and work-in-progress, optimising assembly processes and enhancing product quality.

- Airports: Sorting and routing of checked luggage through security and onto loading zones becomes swift and efficient, improving passenger experience and airport operations.

- Retail: From automated inventory sorting in large stores to moving goods from stockrooms to sales floors, these systems boost operational efficiency and product availability.

- Postal Services: Automated mail and package sorting and routing significantly accelerate delivery times, ensuring efficient postal operations.

A Glimpse into the Future

As AI, sensor technology, and actuator capabilities continue to evolve, the potential of automated conveyor systems expands even further.

- Hyper-intelligent Systems: Deep learning algorithms will further refine route optimisation and decision-making, anticipating changes and proactively adjusting operations.

- Predictive Maintenance: Real-time data analysis will enable advanced fault prediction and prevent downtime, ensuring peak system performance.

- Human-Machine Collaboration: Automation will not replace human workers but rather work alongside them, providing valuable assistance and improving overall safety and productivity.

The Final Conveyor

The future of material handling lies in the hands of intelligent machines. By embracing automated conveyor systems, businesses across industries can unlock unprecedented levels of efficiency, accuracy, and flexibility, gaining a competitive edge and paving the way for a more optimised and productive future. The question is no longer whether to adopt automation but rather how to leverage its immense potential.

Join forces with SmartlogitecX, backed by the technological strength of WayZim Technologies, and lead the charge in Warehouse Automation in Australia and New Zealand. We are more than a service; we are your strategic partner in redefining logistics. Opt for SmartlogitecX to harness the full potential of advanced technology, crafted with an understanding of the local market. Connect with our sales team to begin your journey towards an automated, efficient future.