From Disorder to Precision: The Need for Singulation

In modern parcel logistics, a key bottleneck often emerges where bulk parcels first enter the automation flow. Items arrive in varying shapes, sizes, and packaging—soft bags mixed with cartons, envelopes buried under polybags— forming a disordered two-dimensional mass. Without intervention, this chaotic stream leads to downstream misreads, jams, and reduced throughput.

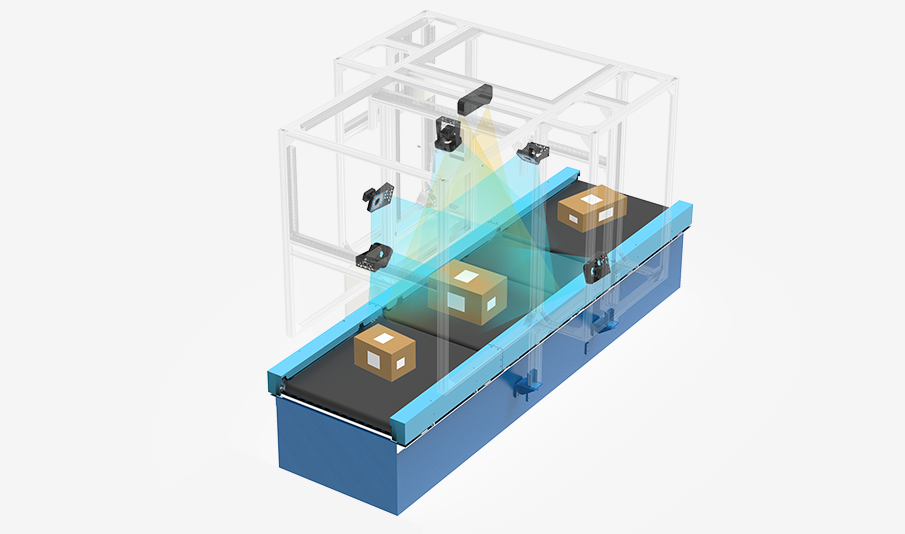

The Wayzim 2D Bulk Flow Singulator System addresses this problem directly. Designed as a front-end conveyor solution, it transforms inconsistent bulk parcel input into a single-file, evenly spaced stream. Using modular servo-driven belt arrays and vision-guided control, the system performs real-time singulation, gapping, and alignment, ensuring parcels are prepared precisely for downstream SmartlogitecX DWS units and high-speed sorters.

System Architecture and Components

System Architecture and Components

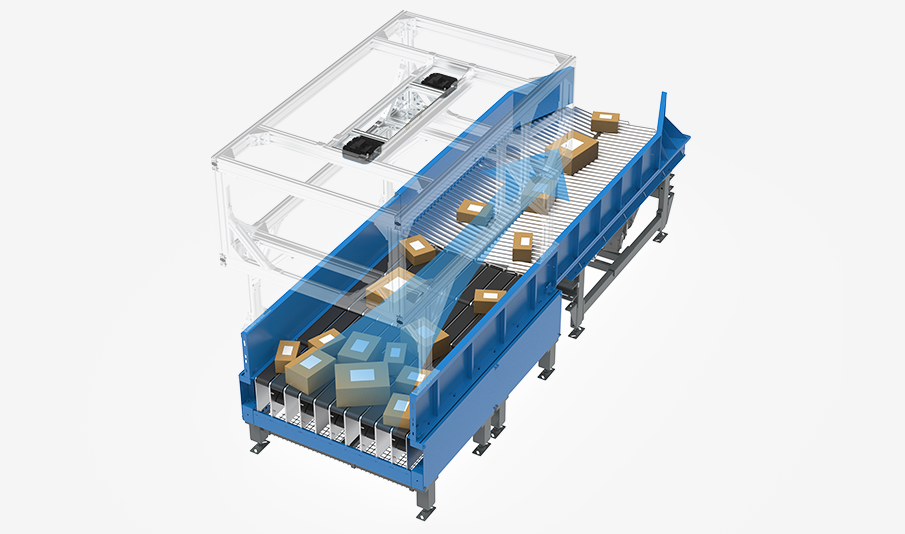

A typical large parcel singulator system includes the following functional modules:

⦁ Input Conveyors: Sensor-driven belts that regulate inflow, ensuring parcels enter the singulator only when downstream capacity allows.

⦁ Gapping Conveyors (Optional): A servo-driven segment that fine-tunes the spacing between parcels using sensor feedback.

⦁ Diverging Section: Angled belts that spread incoming parcels laterally, helping to initiate spacing before singulation. This section may be omitted depending on the layout and software optimisation.

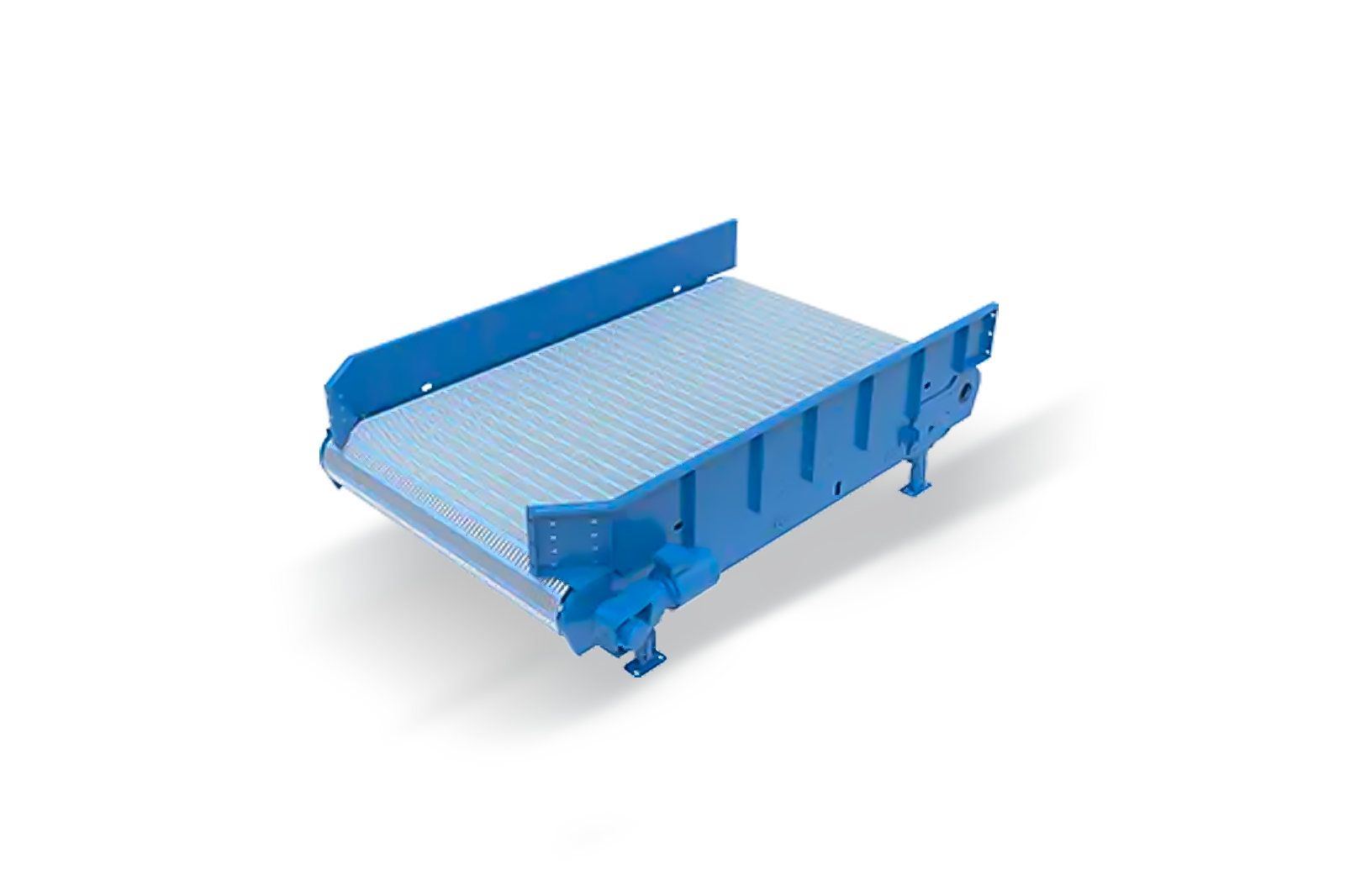

⦁ Singulation Matrix: The core component—a modular belt array, with each module composed of dual narrow belts powered by independent servo motors. These modules dynamically adjust speeds to separate and align parcels.

⦁ Vision System: Overhead industrial cameras capture parcel images, analysed by an industrial PC using deep-learning algorithms. The system recognises and tracks each item with ≥99% accuracy y, including polybags, soft packages, and dark-coloured items.

⦁ Centering Conveyor: A downstream module that ensures parcels are centrally aligned (or side-aligned, depending on the system) to optimise handoff to downstream sorters.

The modular design allows for quick maintenance: belt modules are hot-swappable and can be replaced in under 5 minutes. The system can be scaled by adding or removing modules, depending on throughput and width requirements.

Vision and Control Logic

The singulator’s intelligence relies on a closed-loop control system combining real-time imaging and servo motion. Overhead cameras capture parcel data continuously. The vision software determines position, orientation, and spacing of each parcel. This data is sent to the PLC, which controls each belt module accordingly.

When parcels are detected side-by-side or unevenly spaced, the system calculates appropriate belt speeds to gently separate them.

For example, one belt may accelerate while its neighbour slows, creating a gradual but controlled gap. Singulation targets (typically 300–1200 mm spacing) are configurable via the system’s user interface.

All data is logged and can be exported via the IPC to upper-level control systems (e.g., SCADA, WCS). The system also supports remote control, mode switching, and over-the-air firmware updates.

Operation Modes and Workflow

In normal Singulation Mode, the singulator actively maintains parcel spacing. Parcels are fed in on the input belt until sensor signals indicate entry into the singulation area. As each package enters the matrix of belts, the vision system updates the parcel map every few milliseconds.

The PLC then continuously adjusts the speed of each belt lane according to the programmed strategy and target gap.

The process flow is thus: bulk items arrive on the infeed, sensors start the belts, diverging belts (if present) spread them, cameras capture their positions, and the array of servo belts gently pushes each parcel into the single lane. After singulation, each item passes onto the centering conveyor for lateral alignment, then through the gapping section which finalises the spacing.

If the sorter downstream does not require strict spacing, the operator can switch to Conveying Mode. In this mode, the singulator largely bypasses its active functions: it does not enforce spacing but simply relays parcels downstream. Belts run at fixed speeds, and upstream/downstream conveyors are not tightly synchronised, allowing maximum throughput. (This is useful for overflow or

restart scenarios.)

In practice, Wayzim describes that in Conveying Mode “the

singulator’s primary function is bypassed” and parcels flow freely.

Additional modes enhance efficiency:

for instance, when parcel flow drops below a threshold, the system will enter an energy- saving mode. In this mode, belts can idle or slow to conserve power, automatically resuming full operation when flow increases.

Logic safeguards are built in. If the singulation section becomes overloaded (too many parcels queued), the PLC will issue a “no-entry” signal to the input belt, causing it to stop until space clears. Conversely, when the back-end (e.g. sorter) stops, the singulator halts and automatically restarts in sequence. These interlocks ensure the singulator integrates smoothly in a multi-stage conveyor network.

Supported Parcel Range

The singulator is designed for a wide variety of parcel shapes. Wayzim specifies it can handle items ranging from very small/thin packets up to large cartons.

In practice, parcel dimensions on the order of 150×150×15 mm (thin satchels or flaps) up to about 1000×700×700 mm (large boxes) are accommodated. (Wayzim’s published specs cite an even broader range, e.g. 160×80×1 mm up to 1200×700×700 mm.)

The system processes envelopes, polybags, paper sacks, taped bundles and rigid cartons alike.

To cover different throughput needs and size classes, Wayzim offers two main singulator models (“Small Parcel” and “Large Parcel”).

The small-parcel variant has narrower belt modules and is optimised for lighter loads, whereas the large model has a heavier-duty belt design for bulky items. For extremely small or fragile items (e.g. flats or leaflets), the system can be fitted with soft-backed belts or v-ribbed centering belts to ensure gentle handling.

Running Live Shot Core Values Summary:

Transform chaotic flow into single column flow: 2D Bulk Flow Singulator precisely rectifies batch disorderly parcels into equidistant single columns, which is convenient for efficient access of code scanning/sorting system;

Supported Parcel types Accurate identification and high compatibility:

Real-time separation of various types of parcels, from envelopes to large boxes, through visual identification and independent module control;

Highly integrated and scalable:

modular design + support for docking with 3D equipment, can be flexibly deployed in different scenarios to enhance overall throughput efficiency.

Real-World Application:

Yiwu Express Sorting Center (China) A flagship deployment of the 2D Singulator took place in Yiwu, Zhejiang Province, China. This express sorting hub processes over 12 million parcels and 3 million mail sacks daily. The site includes three large-pivot wheel sorters for bulk items and three dual-layer cross- belt sorters for small parcels, achieving peak handling capacities of 180,000 parcels per hour.

Wayzim’s 2D singulators are deployed at the infeed of the small-parcel lines. Here, they convert dense bulk parcel input into a clean, evenly spaced stream aligned to the specifications of the cross-belt system. By reducing turbulence at the front end, the singulators ensure continuous flow during peak loads, minimise scanning errors, and reduce reliance on manual separation.

In this case, the singulators’ ability to recognise and control mixed-size parcels was critical.

Aerial photo of Yiwu Express Sorting Centre

The client required extremely high sorting accuracy and system availability to meet national- scale logistics demand. By automating spacing and flow regulation, the 2D singulator improved both performance and reliability of the overall system.