E-commerce sales have surged by over 40% in the past three years, placing unprecedented pressure on third-party logistics providers to deliver faster, more accurate order fulfilment whilst managing tighter margins. For 3PLs, the challenges are mounting: persistent labour shortages, escalating operational costs, and clients demanding near-perfect Service Level Agreements that leave little room for error. Warehouse automation solutions have evolved from a competitive advantage to a strategic necessity for modern fulfilment centres. By integrating advanced robotics, intelligent software systems, and automated material handling equipment, 3PLs can fundamentally transform their operations—enhancing efficiency, reducing costs, and building the scalability required to meet fluctuating demand. This guide examines the essential types of warehouse automation solutions, explores their tangible business benefits, and provides practical guidance on selecting the right systems to future-proof your logistics operation.

Why 3PLs Must Embrace Warehouse Automation

The business case for automated warehousing has never been more compelling, particularly for third-party logistics providers navigating today’s volatile market conditions. Automation directly addresses the operational pain points that threaten profitability and growth: unreliable labour availability, spiralling costs, and the relentless pressure to maintain order accuracy whilst accelerating throughput. Industry research demonstrates that 3PLs implementing comprehensive automation strategies report productivity increases of 25-40% within the first year, alongside significant improvements in client retention rates. SmartlogitecX recognises that successful warehouse automation isn’t merely about replacing manual processes—it’s about creating resilient, adaptable operations that can scale efficiently without proportional increases in overhead. The following benefits illustrate why automated warehouse solutions have become essential infrastructure for competitive 3PL operations.

Overcome Labour Shortages and Boost Productivity

Labour availability represents one of the most persistent challenges facing fulfilment centres, with vacancy rates in warehouse operations consistently exceeding 10% across developed markets. Warehouse automation solutions fundamentally restructure labour requirements by assuming responsibility for repetitive, physically demanding tasks such as goods transport, inventory retrieval, and parcel sorting. This reallocation allows human workers to focus on higher-value activities that require judgment, problem-solving, and customer interaction—roles that are typically more satisfying and less physically taxing. Critically, automated systems operate continuously without fatigue, enabling 24/7 operations that dramatically increase throughput without requiring proportional headcount expansion. A properly configured Autonomous Mobile Robot fleet, for instance, can maintain consistent picking speeds throughout extended shifts, whereas human productivity naturally declines after several hours of repetitive work. Beyond pure productivity metrics, automation creates safer work environments by reducing the physical strain associated with manual material handling, thereby decreasing injury rates and improving overall employee satisfaction and retention.

Drastically Reduce Operational Costs

The financial advantages of automation extend well beyond simple labour substitution, touching nearly every aspect of warehouse economics. Direct labour costs typically represent 50-65% of total fulfilment expenses, and automated systems can reduce this burden by 30-50% depending on the degree of implementation. However, the cost savings compound through secondary effects: robotic picking systems virtually eliminate mis-picks, reducing costly returns and the associated reverse logistics expenses that can erode margins by 2-4%. Furthermore, technologies like SmartlogitecX Automated Storage and Retrieval Systems (AS/RS) maximise vertical space utilisation, increasing storage density by 200-400% compared to conventional racking. This spatial efficiency can defer or eliminate the need for warehouse expansion—a capital expenditure that typically requires investments exceeding $50-100 per square foot for new facilities. SmartlogitecX has observed that 3PLs deploying integrated automation solutions frequently achieve return on investment within 18-36 months, after which the ongoing operational savings directly enhance profitability and competitive positioning.

Achieve Near Perfect Accuracy and Faster Fulfilment

Order accuracy stands as a critical metric for 3PL success, directly influencing client satisfaction, contract renewals, and reputation within the industry. Manual picking processes, even with experienced warehouse staff, typically achieve accuracy rates of 96-98%—which translates to 200-400 errors per 10,000 orders, each potentially damaging client relationships and incurring correction costs. Robotic warehouse solutions employ barcode scanning, RFID verification, and machine vision systems that routinely achieve accuracy exceeding 99.9%, effectively eliminating mis-picks as a significant operational concern. This precision directly supports SLA compliance, ensuring that 3PLs consistently meet contracted performance targets that increasingly differentiate service providers in competitive tenders. Beyond accuracy, automation streamlines the entire fulfilment workflow: goods-to-person systems eliminate unproductive travel time, sortation systems accelerate parcel routing, and integrated warehouse management systems optimise task sequencing. The cumulative effect reduces order cycle times by 40-60%, enabling same-day or next-day delivery capabilities that have become standard expectations in e-commerce fulfilment.

Essential Automated Warehouse Systems for 3PLs

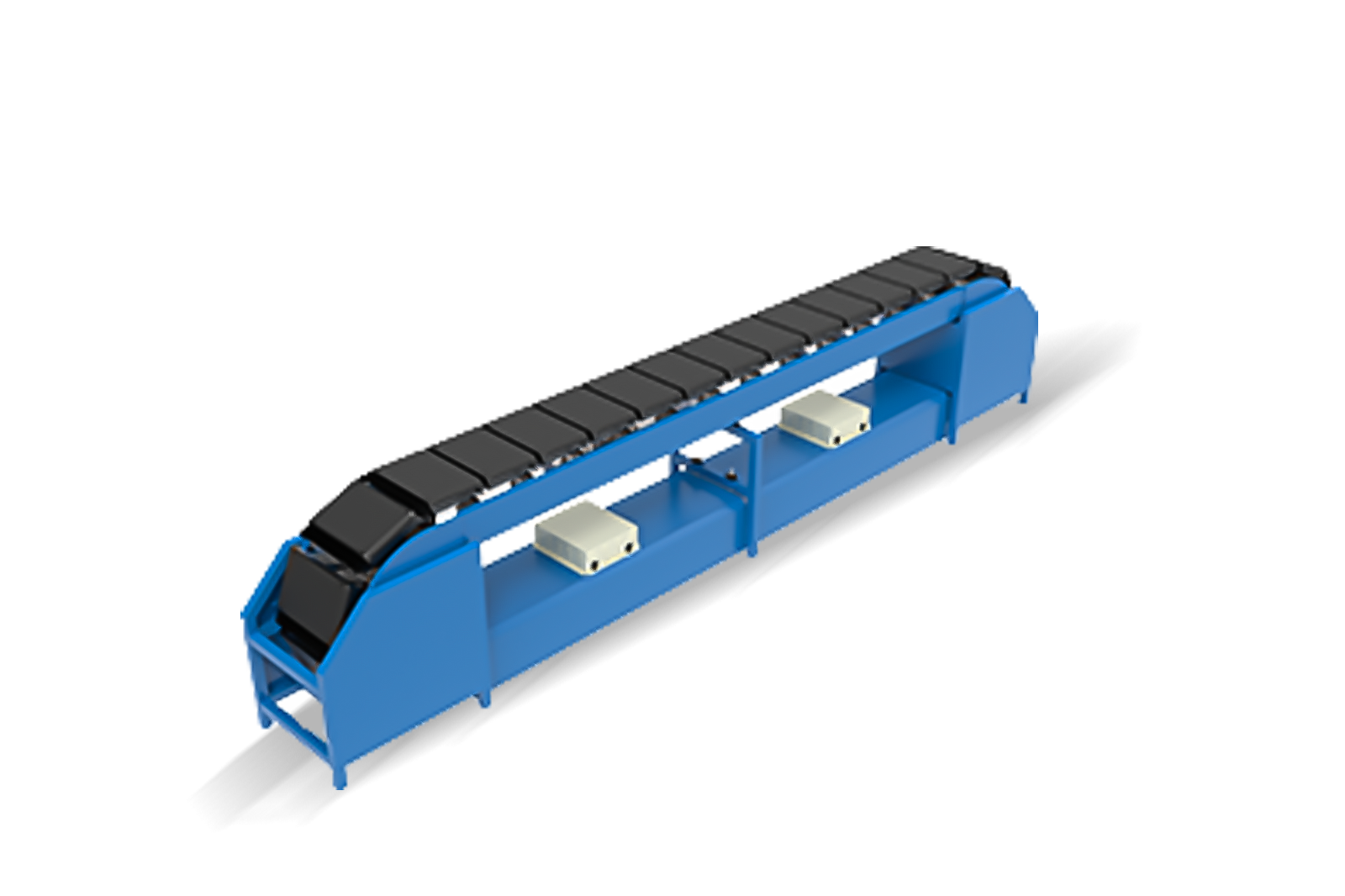

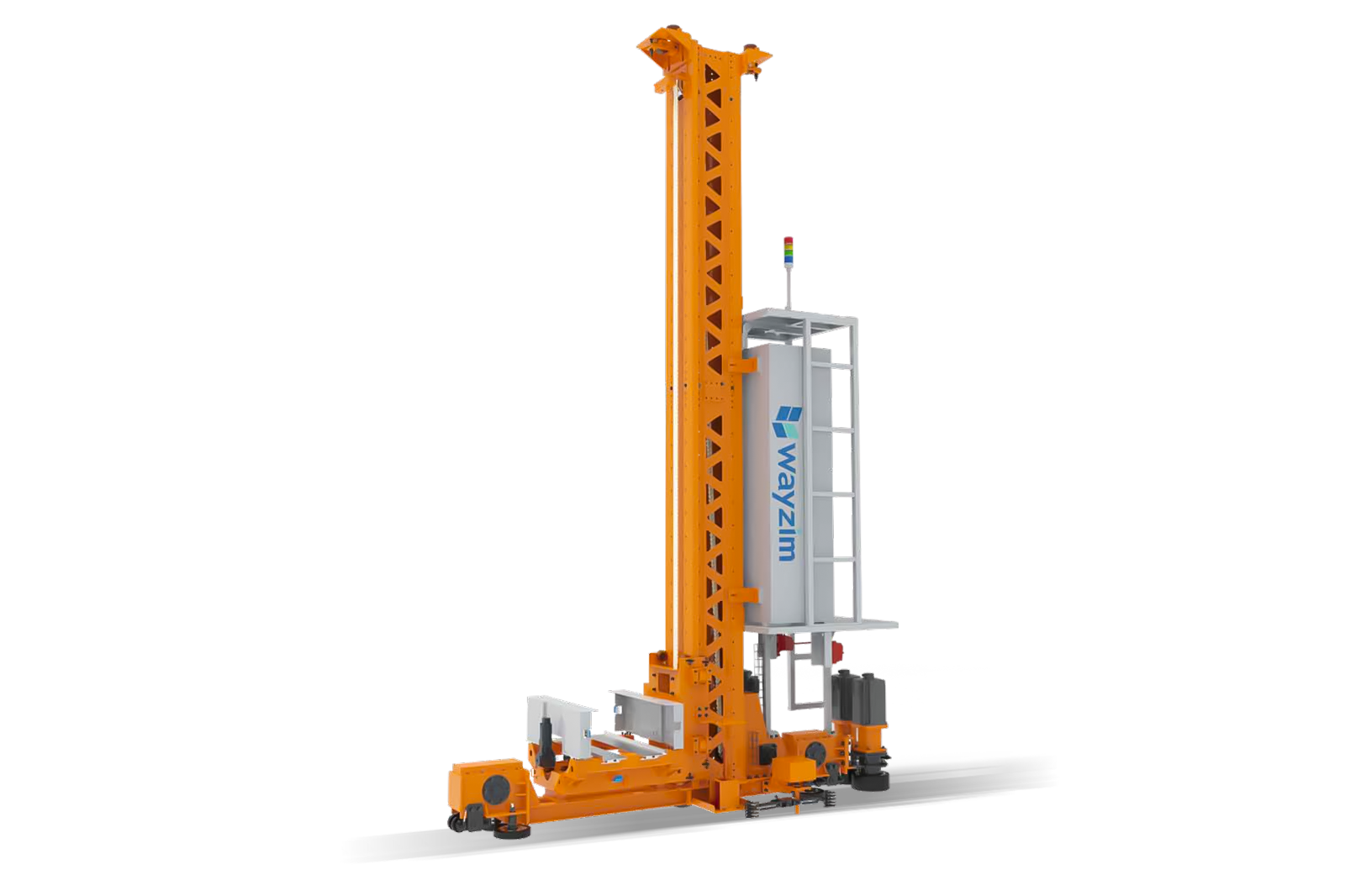

Understanding the technology landscape is crucial for 3PL decision-makers evaluating automation investments. Modern warehouse automation encompasses several distinct but complementary technologies, each addressing specific operational requirements within the fulfilment workflow. Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) represent the most flexible category: AGVs follow fixed paths using magnetic strips or wires, making them reliable for repetitive transport routes, whilst AMRs employ dynamic navigation using sensors and mapping software, allowing them to adapt routes in real-time and collaborate safely with human workers. Latent AGVs excel at moving entire shelving units to ergonomic picking stations, fundamentally changing warehouse layouts, whilst heavy-duty Fork AGVs automate pallet transport tasks traditionally performed by forklift operators. Automated Storage and Retrieval Systems (AS/RS) utilise computer-controlled vehicles or cranes to store and retrieve goods from high-density racking configurations, maximising vertical space and dramatically increasing storage capacity within existing footprints. Robotic picking systems range from articulated arms that can grasp individual items to sophisticated sortation systems—such as Express Parcel Sorting Systems—designed specifically for the high-volume, multi-destination requirements typical of e-commerce fulfilment. Finally, Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS) serve as the operational intelligence layer, integrating all hardware components, optimising workflows in real-time, and providing the inventory visibility and performance analytics essential for data-driven decision-making. SmartlogitecX emphasises that successful automation projects rarely involve isolated technologies; rather, they integrate multiple systems into cohesive material handling ecosystems tailored to specific operational requirements and client profiles.

A Practical Guide to Choosing Your Automation Solution

Selecting appropriate warehouse automation solutions requires systematic analysis rather than technology-led decision-making. The following framework guides 3PL operators through the strategic considerations essential for successful implementation.

Assess Your Current Operations begins by identifying specific operational bottlenecks that constrain throughput, compromise accuracy, or inflate costs. Comprehensive analysis of order data, SKU characteristics, and throughput patterns reveals whether picking speed, storage capacity, sortation accuracy, or labour availability represents the primary constraint. For instance, operations handling predominantly small-item, high-SKU-count inventories face different challenges than those managing pallet-level movements of limited SKU ranges. Defining clear, measurable objectives—whether reducing pick times by 30%, increasing storage density by 200%, or achieving 99.95% accuracy—provides the foundation for evaluating automation proposals against tangible business outcomes rather than abstract technological capabilities.

Evaluate Scalability and Flexibility recognises that 3PL operations rarely remain static: client portfolios evolve, seasonal peaks intensify, and service offerings expand over time. Automation investments must accommodate growth without requiring complete system replacements. Modular systems that allow incremental capacity additions—adding AMR units to an existing fleet, extending AS/RS aisles, or expanding sortation loops—provide financial flexibility and operational continuity. Equally important is adaptability to handle diverse product types and order profiles, as 3PLs typically serve multiple clients with varying requirements. Solutions that can efficiently process both individual e-commerce orders and bulk wholesale shipments maximise asset utilisation and client versatility.

Prioritise Integration Capabilities addresses what industry experts identify as the most common implementation challenge: ensuring new automation hardware communicates seamlessly with existing warehouse management systems. SmartlogitecX consistently advises clients that automation solutions creating data silos or requiring extensive custom middleware compromise operational visibility and increase long-term support costs. Modern automation vendors should provide standardised APIs and proven integration frameworks that connect smoothly with major WMS platforms, enabling unified inventory visibility, coordinated task allocation, and comprehensive performance reporting across both automated and manual operations.

Calculate the Total Cost of Ownership extends financial analysis beyond initial capital expenditure to encompass the true economic impact over the system’s operational lifespan. Implementation costs including facility modifications, system installation, and operational disruption during commissioning can add 15-25% to equipment purchase prices. Ongoing expenses—software licensing, preventative maintenance contracts, spare parts inventories, and periodic technology upgrades—accumulate substantially over 5-10 year planning horizons. Staff training requirements and the potential need for specialist technical support should also factor into TCO calculations. Comprehensive analysis typically reveals that whilst automation requires significant upfront investment (ranging from $100,000 for entry-level solutions to several million dollars for fully integrated systems), the operational savings and revenue-enhancing capabilities justify the expenditure when aligned with strategic business objectives.

Final Thoughts on Future-Proofing Your 3PL Operations

Warehouse automation solutions have transitioned from optional efficiency enhancements to fundamental infrastructure for 3PLs seeking sustainable competitive advantage in increasingly demanding logistics markets. The evidence is compelling: automation delivers measurable improvements in efficiency, cost reduction, and accuracy whilst building operational resilience against labour volatility and capacity constraints. However, successful implementation requires moving beyond technology fascination to strategic planning grounded in operational realities, financial discipline, and long-term business objectives. The 3PLs thriving in the current environment are those recognising automation not as a single project but as an ongoing evolution of capabilities aligned with client needs and market dynamics. For logistics operators currently relying on manual processes, the question is no longer whether to automate, but rather which systems to implement first and how to structure phased deployment that minimises disruption whilst building towards comprehensive operational transformation. SmartlogitecX encourages fulfilment centre operators to begin this journey by conducting honest assessments of current operational limitations and engaging with automation specialists who understand the unique requirements of third-party logistics environments.

Frequently Asked Questions

1.What problems does automated warehousing solve for 3PLs?

Automated warehousing addresses several critical operational challenges for third-party logistics providers: persistent labour shortages that constrain capacity, high operational costs that erode profitability, human error in picking that damages client relationships, inefficient space utilisation that necessitates costly facility expansion, and difficulties scaling operations to accommodate seasonal demand fluctuations or rapid client growth.

2.How does automation increase efficiency in order fulfilment?

Automation accelerates every stage of the fulfilment workflow—receiving, put-away, picking, packing, and sorting—by eliminating unproductive travel time, enabling continuous 24/7 operations, and maintaining consistent processing speeds regardless of shift duration. Goods-to-person systems bring inventory directly to stationary operators, whilst intelligent task allocation ensures optimal work sequencing and resource utilisation.

3.What are the main advantages of automated warehouses for third-party providers?

The primary advantages include significant cost savings through reduced labour requirements and improved space utilisation, enhanced order accuracy exceeding 99.9% that supports SLA compliance, faster fulfilment times enabling same-day and next-day delivery capabilities, operational scalability without proportional cost increases, and strengthened competitive positioning that helps attract and retain valuable client relationships.

4.Does automation improve labour utilisation in warehouses?

Automation fundamentally improves labour utilisation by reallocating human workers from physically demanding, repetitive tasks such as goods transport and basic picking to more complex, value-added roles including quality control, system oversight, exception handling, and customer service activities. This creates more satisfying work environments whilst maximising the unique capabilities of human judgment and problem-solving.

5.What is the typical cost of warehouse automation?

Automation costs vary enormously depending on technology selection, implementation scale, and operational complexity. Entry-level solutions such as collaborative robots or basic pick-to-light systems might require investments from $50,000-$150,000, whilst comprehensive implementations including AS/RS, extensive AMR fleets, and integrated sortation systems can exceed several million dollars for large-scale fulfilment centres.

6.Are there affordable automation options for smaller fulfilment centres?

Numerous affordable automation options exist for smaller operations, including entry-level collaborative robots (cobots) that work safely alongside human staff, pick-to-light systems that improve accuracy without major infrastructure changes, and scalable Autonomous Mobile Robot platforms where 3PLs can begin with a small fleet and expand capacity incrementally as operational requirements and financial capabilities grow.

7.How do you integrate new automation systems into existing operations?

Integration typically proceeds through phased implementation that minimises operational disruption. Success requires comprehensive planning, close collaboration with automation vendors who understand logistics operations, thorough testing protocols before full deployment, and ensuring seamless communication between new systems and existing WMS platforms through standardised APIs rather than complex custom middleware.

8.What are the biggest challenges of adopting warehouse automation?

The principal challenges include securing capital for substantial upfront investments, integrating new technologies with legacy software systems that may lack modern connectivity standards, managing organisational change as staff adapt to new workflows and technologies, and ensuring selected solutions provide sufficient flexibility to accommodate future business evolution without requiring premature replacement.

9.How do robots improve order accuracy in fulfilment centres?

Robotic systems employ barcode scanning, RFID verification, and machine vision technologies that confirm item identity at every handling point, virtually eliminating the mis-picks that occur in manual processes. Robots follow precise, software-guided instructions without the distraction, fatigue, or interpretation errors inherent in human operations, routinely achieving accuracy rates exceeding 99.9% compared to 96-98% for manual picking.

10.What are some emerging trends in warehouse robotics?

Emerging trends transforming warehouse automation include artificial intelligence and machine learning algorithms that enable systems to optimise workflows autonomously, increased deployment of collaborative robots (cobots) designed for safe human-robot interaction in shared workspaces, and Robotics-as-a-Service (RaaS) business models that reduce capital requirements by allowing 3PLs to lease automation capabilities rather than purchasing equipment outright.