The global e-commerce market has surged by 300% over the past five years, placing unprecedented pressure on supply chains to deliver faster, more accurate fulfilment than ever before. This explosive growth has transformed warehouse automation from a competitive advantage into an essential requirement for businesses seeking to thrive in today’s demanding logistics landscape. Modern warehouse automation systems represent the critical solution for organisations looking to enhance their logistics efficiency, reduce operational costs, and gain a decisive competitive edge in an increasingly digital marketplace. Throughout this comprehensive guide, we’ll explore the key benefits of automation, examine the core technologies driving this transformation, provide practical implementation strategies, and look ahead to the future trends shaping the industry, equipping you with the knowledge needed to make informed decisions about your warehouse operations.

Key Benefits of Warehouse Mechanisation for Your Business

Implementing automated warehouse solutions delivers transformative advantages that extend far beyond simple efficiency gains, fundamentally reshaping how businesses approach their logistics operations. The most immediate benefit is the dramatic increase in operational efficiency and productivity, as automation enables facilities to operate continuously, processing orders 24/7 whilst maintaining consistent performance levels that human workforces simply cannot match. Modern warehouse automation solutions typically deliver significant labour and operational cost savings, with many organisations reporting ROI within 18-24 months through reduced labour costs, minimised errors that lead to fewer returns, and optimised energy consumption through intelligent system management. Order accuracy improvements are equally impressive, as technologies like advanced WMS, integrated barcode scanners, and precision robotics work together to achieve near-perfect order accuracy rates exceeding 99.9%, whilst providing real-time inventory visibility that eliminates stock discrepancies. Beyond the numbers, automation enhances workplace safety by taking over physically demanding or hazardous tasks, dramatically reducing workplace injuries whilst enabling staff to be reskilled for higher-value roles that contribute more meaningfully to business growth. Perhaps most strategically, automated systems optimise warehouse space utilisation through vertical storage solutions and intelligent layout designs, increasing storage density by up to 60% and potentially delaying or eliminating the need for costly facility expansion.

A Guide to Core Automation Technologies

Understanding the various automation technologies available is essential for making informed decisions about which solutions best suit your specific operational needs and business objectives.

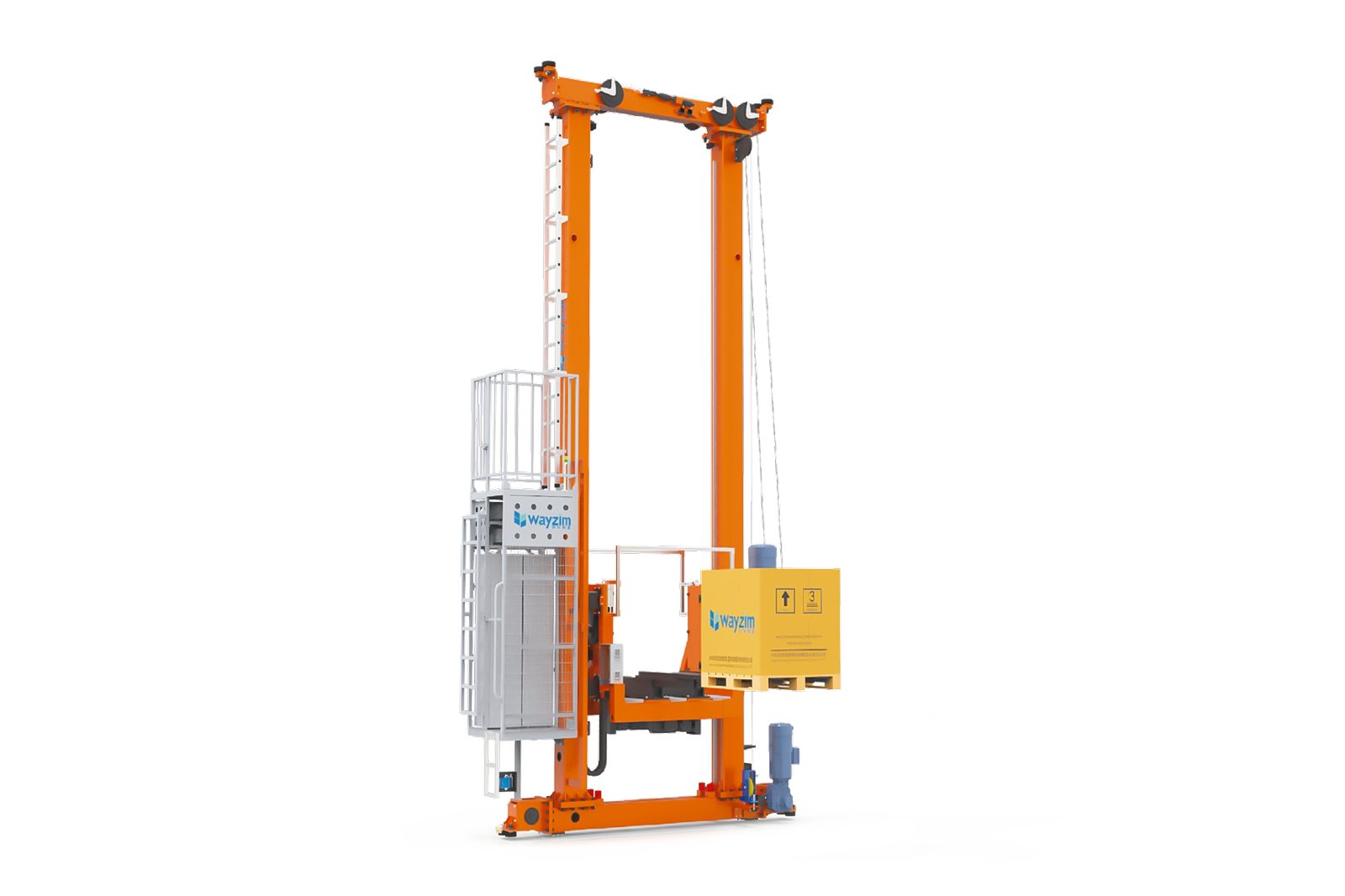

Automated Storage and Retrieval Systems ASRS

SmartlogitecX Automated Storage and Retrieval Systems represent the pinnacle of warehouse storage efficiency, functioning as sophisticated mechanical systems that automatically store and retrieve goods with remarkable speed and precision. These systems encompass various configurations, from Unit-Load ASRS designed for pallet handling to Mini-Load systems optimised for smaller items and cartons, each offering unique advantages for different operational requirements. The transformative impact of ASRS extends beyond simple storage, as these intelligent warehousing solutions maximise storage density by utilising vertical space that traditional racking cannot efficiently access, whilst simultaneously reducing labour requirements by up to 70% and providing unprecedented inventory management accuracy through integrated tracking systems. SmartlogitecX’s automated storage solutions exemplify this technology’s potential, offering businesses the opportunity to transform their warehouse management through systems that seamlessly integrate with existing operations whilst providing the scalability needed for future growth.

The Role of Robotics in Modern Warehousing

Warehouse robotics has evolved from science fiction to operational reality, fundamentally changing how goods move through distribution centres and fulfilment facilities. The landscape of robotic automation includes two primary categories that serve distinct operational needs: • SmartlogitecX Automated Guided Vehicles (AGVs) – Follow predetermined paths using magnetic strips or wires, providing reliable, consistent material transport for repetitive tasks • Autonomous Mobile Robots (AMRs) – Utilise advanced sensors, AI, and machine learning to navigate dynamically, offering superior flexibility and adaptability to changing warehouse layouts.

The implementation of robotic picking systems, particularly Goods-to-Person solutions, has revolutionised order fulfilment by bringing products directly to human operators, reducing travel time by up to 90% and dramatically increasing picking productivity. These AGVs & AMRs work collaboratively within modern automated systems, creating a harmonious blend of human expertise and robotic efficiency that maximises throughput whilst maintaining the flexibility needed for complex operations.

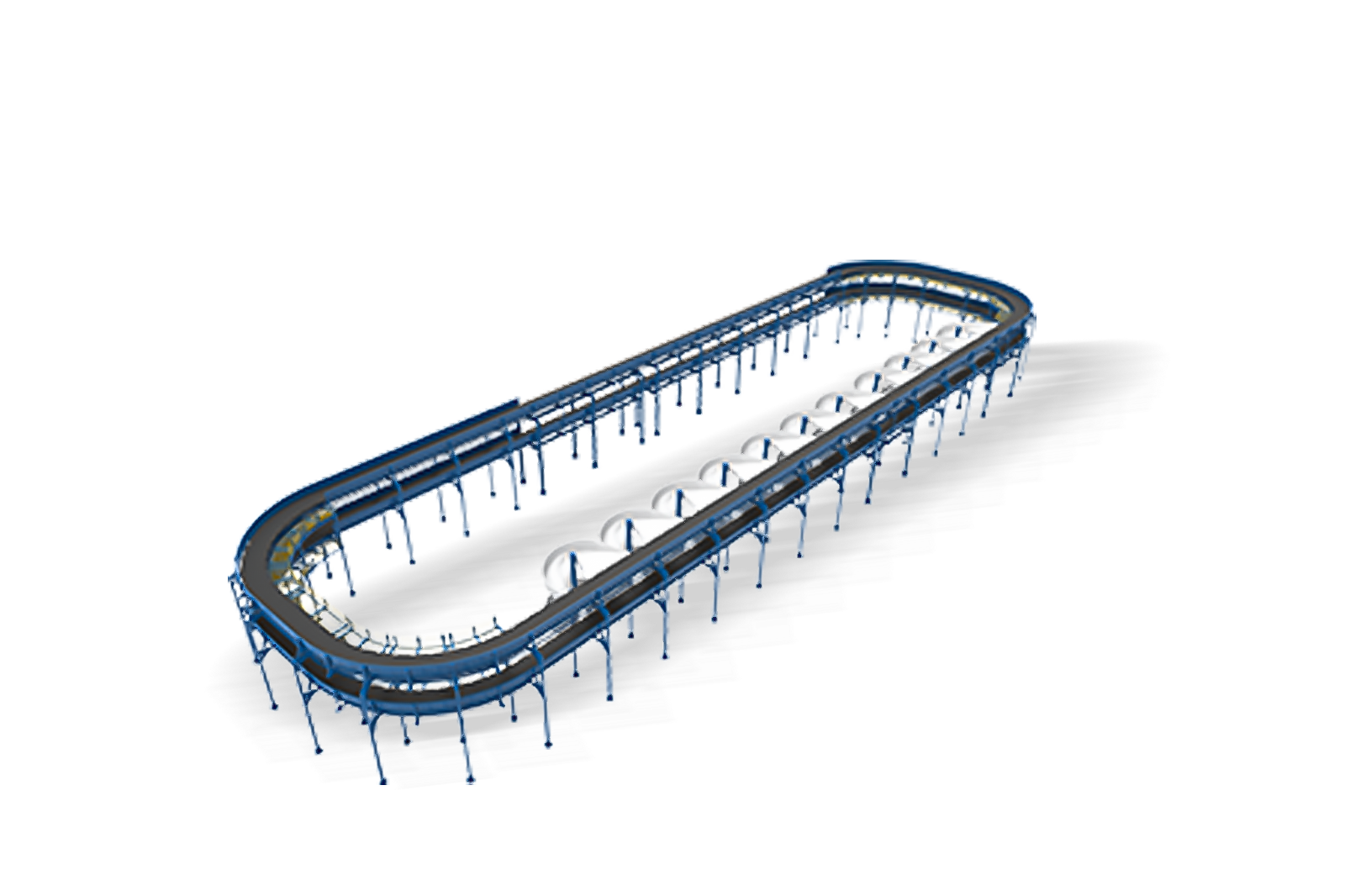

Essential Warehouse Conveyor and Sortation Systems

Auto conveying systems and automated sortation systems form the circulatory system of modern warehouses, ensuring smooth, continuous material flow from receiving docks through to shipping areas. The diversity of conveyor technologies available – from traditional belt conveyors for general merchandise to sophisticated roller conveyors for heavy loads and intelligent pop-up sorters for high-speed routing – enables businesses to create customised material handling solutions that match their specific product profiles and throughput requirements. These warehouse conveyor systems prove particularly vital in high-volume operations, especially within e-commerce and parcel processing facilities where thousands of items must be accurately sorted and routed every hour, making them indispensable components of any comprehensive automation strategy.

How to Choose the Right Automation Solution

Selecting the appropriate warehouse automation products requires a methodical approach that aligns technology choices with business objectives and operational realities. Begin by conducting a thorough assessment of your current operations, analysing existing workflows to identify bottlenecks, inefficiencies, and pain points whilst collecting comprehensive data on throughput rates, order profiles, and labour costs to establish a baseline for improvement. Next, define clear objectives and KPIs that will guide your automation journey – whether your primary goals involve increasing processing speed, reducing error rates, cutting labour costs, or achieving a combination of these benefits, having specific, measurable targets ensures your investment delivers tangible results. When evaluating technology and scalability options, carefully match automation solutions to your specific challenges whilst ensuring chosen systems can accommodate future growth without requiring complete replacement. Finally, plan meticulously for integration and change management, recognising that successful automation implementation requires seamless connection with existing WMS and warehouse control systems, alongside comprehensive training programmes that prepare your workforce for new roles and responsibilities within the automated environment.

Future Trends Shaping Warehouse Logistics

The warehouse automation landscape continues to evolve rapidly, driven by emerging technologies that promise even greater efficiency and capability improvements. Artificial intelligence and machine learning are making automation systems increasingly intelligent, enabling predictive analytics for demand forecasting that reduces inventory holding costs, dynamic route optimisation for AMRs that adapts to real-time conditions, and preventative maintenance alerts that minimise costly downtime. The rise of collaborative robots, or cobots, represents a paradigm shift in human-robot interaction, as these advanced systems work safely alongside human employees to augment their capabilities rather than replace them entirely, creating a more flexible and adaptable workforce. Sustainability considerations are becoming increasingly important, with businesses seeking energy-efficient automation solutions that reduce both operational costs and environmental impact, whilst micro-fulfilment centres enabled by compact automation technologies bring inventory closer to end customers, supporting ultra-fast delivery expectations in urban markets.

SmartlogitecX: Your Partner in Warehouse Automation Excellence

SmartlogitecX stands as a leading comprehensive solution provider for intelligent logistics systems across Australia, empowered by their strategic partnership with Wayzim Technologies to set new standards in warehouse automation. From their headquarters at Level 11/10 Carrington St, Sydney NSW 2000, the company delivers innovative robot solutions and future-proof products that serve businesses throughout New South Wales, Victoria, Queensland, Western Australia, and South Australia. Operating under the guiding principle of “Innovation in Technology, Ingenuity in Quality,” SmartlogitecX provides comprehensive solution systems covering multi-industry applications including express parcel intelligent sorting, smart airport automatic sorting, intelligent warehousing, and e-commerce retail warehousing and distribution. Their commitment extends beyond merely supplying equipment; they work collaboratively with forward-thinking Australian companies to create bespoke automation experiences that not only meet immediate operational needs but also position businesses for long-term success in an increasingly automated future. The company’s philosophy that “when robots and automation are implemented in a business effectively, they don’t replace jobs” underscores their dedication to creating innovative workplaces where technology augments human capabilities rather than displacing workers.

Getting Started With Your Automation Strategy

Warehouse automation has evolved from a competitive advantage to an essential investment for businesses serious about logistics efficiency and sustainable growth in today’s demanding market environment. The benefits are clear and compelling: • Dramatic improvements in operational efficiency and throughput • Substantial cost savings through reduced labour and error rates • Enhanced accuracy and real-time inventory visibility • Improved workplace safety and employee satisfaction • Optimised space utilisation and scalability

Beginning your automation journey starts with conducting a comprehensive internal audit of current processes, identifying pain points, and establishing clear improvement objectives that align with your broader business strategy. Engaging with warehouse automation companies and specialists like SmartlogitecX can provide valuable insights into tailored warehouse automation services that address your specific operational challenges whilst maximising return on investment.

Frequently Asked Questions

1.What is the main purpose of warehouse automation?

The primary purpose of warehouse automation is to enhance operational efficiency, reduce costs, and improve accuracy in logistics operations by replacing manual processes with intelligent mechanical and digital systems that work faster, more consistently, and with fewer errors than traditional methods.

2.How does automation improve order fulfilment accuracy?

Automation improves order fulfilment accuracy through integrated technologies like barcode scanning, RFID tracking, and robotic picking systems that virtually eliminate human error, achieving accuracy rates exceeding 99.9% whilst providing real-time inventory visibility.

3.What are the biggest cost savings from implementing automated warehouse solutions?

The most significant cost savings come from reduced labour costs (typically 50-70% reduction), decreased error rates leading to fewer returns, optimised space utilisation delaying facility expansion, and improved energy efficiency through intelligent system management.

4.What is the difference between an AGV and an AMR?

AGVs (Automated Guided Vehicles) follow fixed paths using physical guides like magnetic strips, whilst AMRs (Autonomous Mobile Robots) use sensors and AI to navigate dynamically, offering greater flexibility and adaptability to changing warehouse layouts.

5.How does an Automated Storage and Retrieval System (ASRS) optimise space?

ASRS optimises space by utilising vertical height effectively, often reaching 10-15 metres high, storing items in high-density configurations, and eliminating wide aisles needed for human access, potentially increasing storage capacity by 60% or more.

6.Will automation replace all human jobs in a warehouse?

No, automation typically transforms rather than eliminates human roles, with workers transitioning from physical tasks to supervisory, maintenance, and quality control positions that require human judgement and problem-solving skills.

7.What are the first steps to implementing an automated system?

Begin with a comprehensive operational assessment, identify specific pain points and objectives, evaluate suitable technologies, calculate ROI projections, and develop a phased implementation plan that minimises disruption to ongoing operations.

8.How long does it typically take to see a return on investment (ROI)?

Most warehouse automation implementations achieve ROI within 18-24 months, though this varies based on the scale of implementation, chosen technologies, and operational volumes.

9.Can automation be implemented in an existing warehouse facility?

Yes, many automation solutions are designed for retrofit installation in existing facilities, though some modifications to layout, flooring, or infrastructure may be required depending on the chosen technologies.

10.What role does a Warehouse Management System (WMS) play in automation?

A WMS serves as the central nervous system of automated warehouses, coordinating all automated equipment, managing inventory data, optimising workflows, and providing real-time visibility across all operations.

11.How does mechanisation improve supply chain speed and throughput?

Mechanisation enables 24/7 operations, eliminates manual handling delays, optimises routing and picking sequences, and processes multiple orders simultaneously, potentially increasing throughput by 200-300%.

12.What challenges should be expected when adopting logistics automation?

Common challenges include initial capital investment requirements, integration with existing systems, workforce training and change management, temporary disruption during implementation, and ongoing maintenance requirements for sophisticated equipment.