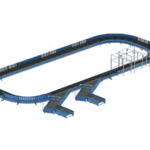

In today’s fast-paced production and distribution environments, managers are constantly looking for ways to increase efficiency, capacity, and throughput while reducing costs. One solution that has gained popularity in recent years is automated conveyor systems. These systems are designed to streamline the processing of large quantities of conveyable inventory, including cartons, cases, totes, bags, and stuffed envelopes, into pallets, skids, gaylords, tubs, and wheeled carts.

The benefits of conveying and sorting automation are numerous.

- Enables automatic product flow between and within functional areas

- Increases capacity and throughput rates

- Accommodates workflow processing optimisation

- Tracks each load for precise accountability and control

- Integrates with inventory storage and order picking sub-systems

- Has a reconfigurable mechanical and control architecture that is scalable for future growth

RELATED: Exploring the Efficiency of Automatic Conveyor Systems

Visibility, traceability, and insight with IIoT connectivity

- Productivity, efficiency, and accuracy

- Balanced, synchronised flow

- System parameters that adjust to current conditions

- Minimal employees to operate

- Short order processing times

- Lowest cost per case/item handled

Conveyor systems are used in various industries, including,

- Parcels and postal

- Wholesale, retail, and B2B

- Food and beverage manufacturing

In the parcels and postal industry, automated conveyor systems are used for cross-docking of parcels, both inbound and outbound. In the wholesale, retail, and B2B industries, conveyor systems are used in distribution centres (DCs) to assemble orders efficiently and accurately at the lowest cost per case. In the food and beverage industry, conveyor systems transport cartons and cases from production to storage and/or palletising. Automated conveyor systems offer a wide range of benefits and are used in various industries to streamline product flow and sorting processes.

By investing in a conveyor system, production and distribution managers can increase efficiency, capacity, and throughput while reducing costs, enabling them to stay competitive in today’s fast-paced business environment.

SmartlogitecX, empowered by WayZim Technologies, is at the forefront of revolutionising Warehouse Automation in the Australian and New Zealand market. Be a part of the logistics transformation. Embrace SmartlogitecX’s locally-focused, globally-backed expertise. Redefine your operations, harnessing the power of technology made for Australia and New Zealand. Ready to elevate your logistics? Reach out SmartlogitecX warehouse automation sales team for your customised warehouse automation solution.

Read more: Automated Conveyor Systems: Transforming the Landscape of Warehousing and Manufacturing.