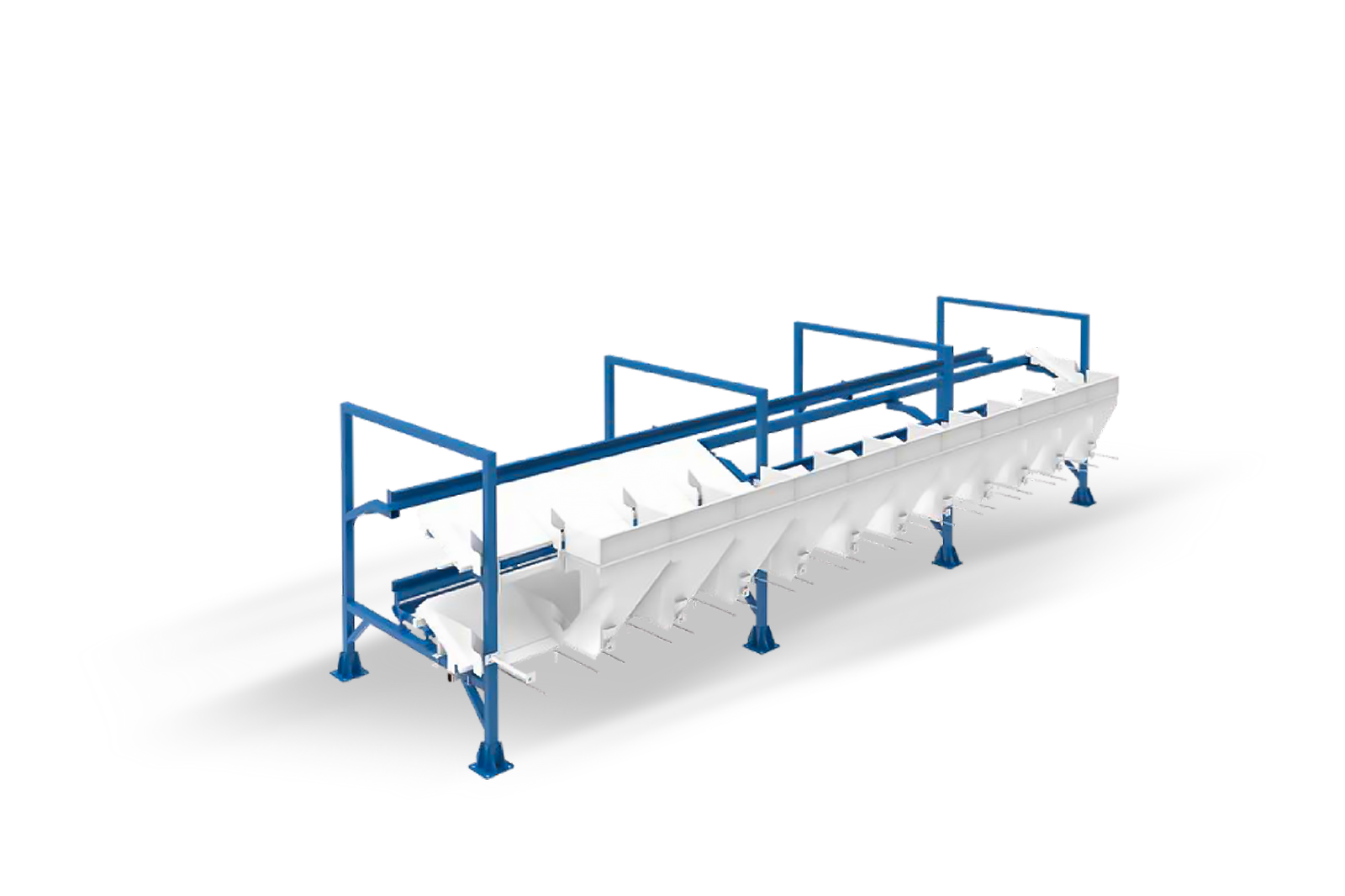

Chutes, those familiar sloped tunnels, play a surprisingly vital role in modern logistics and material handling. Their simple yet effective design helps move goods efficiently and safely, making them a versatile tool across various industries. What is a Chute? A chute is a narrow, inclined passage designed to guide the flow of objects through gravity. […]

Package sorting and distribution centres are the beating heart of the logistics industry. As eCommerce continues its meteoric rise, the demand for faster and more efficient package handling has reached new heights. Automated sortation systems provide the cutting-edge technology needed to keep up with ever-increasing consumer demand. Automated sortation systems accelerate the speed, accuracy and […]

In the age of instant gratification and e-commerce dominance, the speed and efficiency of logistics have become paramount. Gone are the days of slow, manual sorting processes; automated sortation systems are now the driving force behind streamlined package delivery, order fulfilment, and warehouse operations. These intelligent machines are transforming the industry, offering a glimpse into […]

In today’s fast-paced world, logistics are the lifeblood of any business. Consumers expect their orders to be delivered quickly and efficiently, putting immense pressure on companies to optimise their supply chains. This is where automated sortation systems come in as game-changers, transforming the way we handle package sorting and distribution. What are Automated Sortation Systems? […]

In the world of logistics and warehouse management, single-piece separation plays a crucial role in ensuring efficient order fulfilment and inventory control. It refers to the process of isolating individual units from a bulk quantity, making them readily available for picking and packing. This seemingly simple process offers significant benefits in terms of accuracy, efficiency, […]

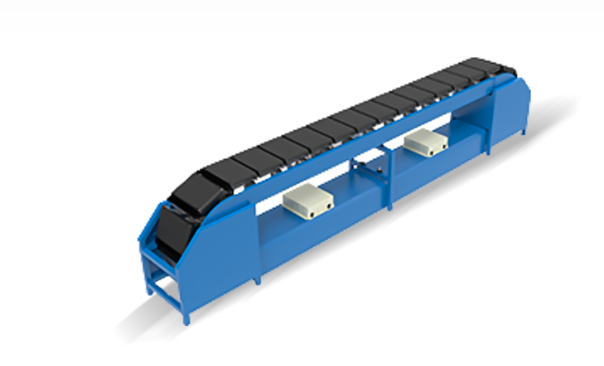

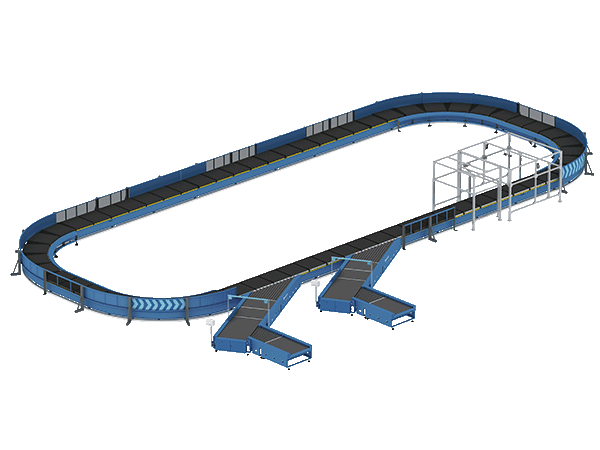

In the fast-paced world of logistics, efficient order fulfilment requires reliable and adaptable solutions. The Linear Sorter is a vital tool in this realm, offering a straightforward yet effective approach to sorting and directing packages in warehouses and distribution centres. What is a Linear Sorter? Unlike its more intricate cousin, the Cross Belt Sorter, the […]

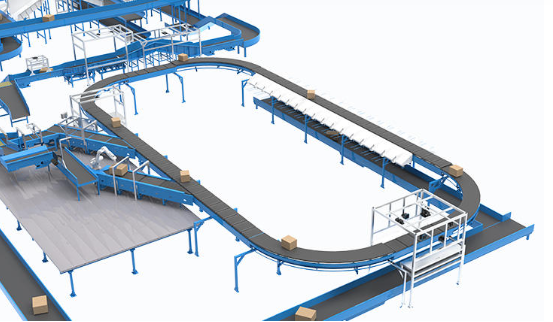

The Cross Belt Sorter (CBS) is a vital component of modern warehouse automation, playing a crucial role in directing and sorting packages for efficient order fulfilment. Its unique design and operation contribute to faster processing times, improved accuracy, and a more streamlined workflow. What is a Cross-Belt Sorter? Imagine a series of short conveyor belts […]

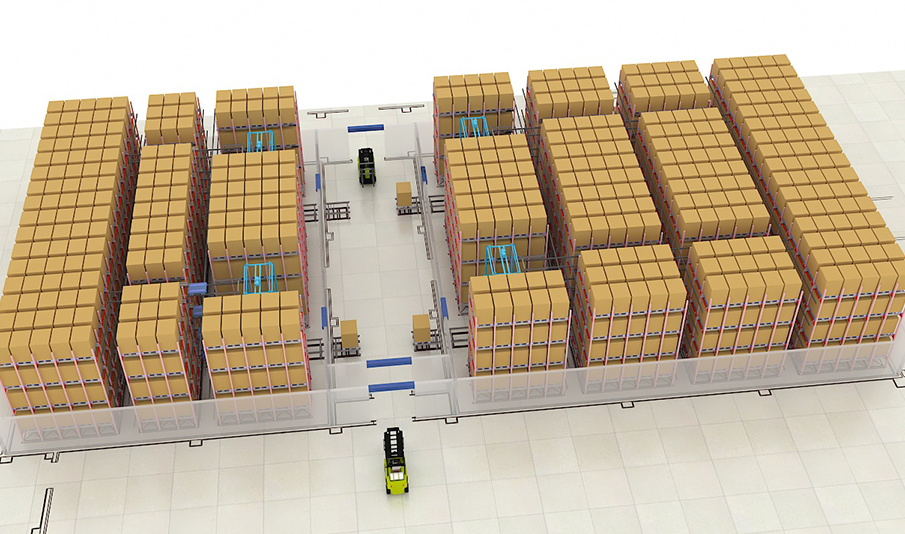

The Pallet Four-way Shuttle is a cutting-edge warehouse automation technology designed to revolutionise storage and retrieval of palletised goods. This innovative system offers unmatched flexibility, efficiency, and space utilisation, making it a compelling choice for modern warehouses. What is a Pallet Four-way Shuttle? Imagine a self-propelled robot, equipped with forks, navigating within a network of […]

A Tote Stacker Crane, also known as a Mini-load Crane, is a specialised type of AS/RS (Automated Storage and Retrieval System) designed specifically for handling totes and small containers in warehouses and distribution centres. Features Compact design: The smaller footprint allows for efficient use of space, especially in warehouses with limited floor area. Flexibility: The […]

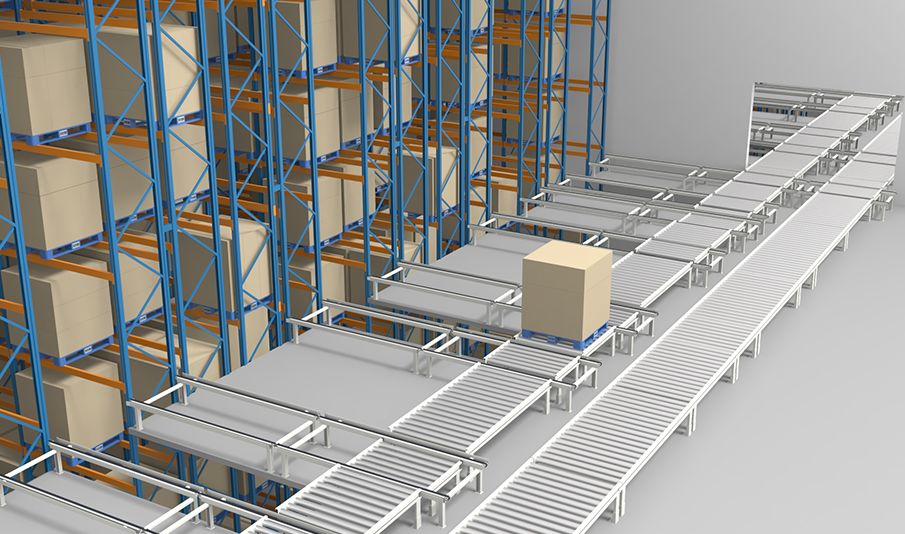

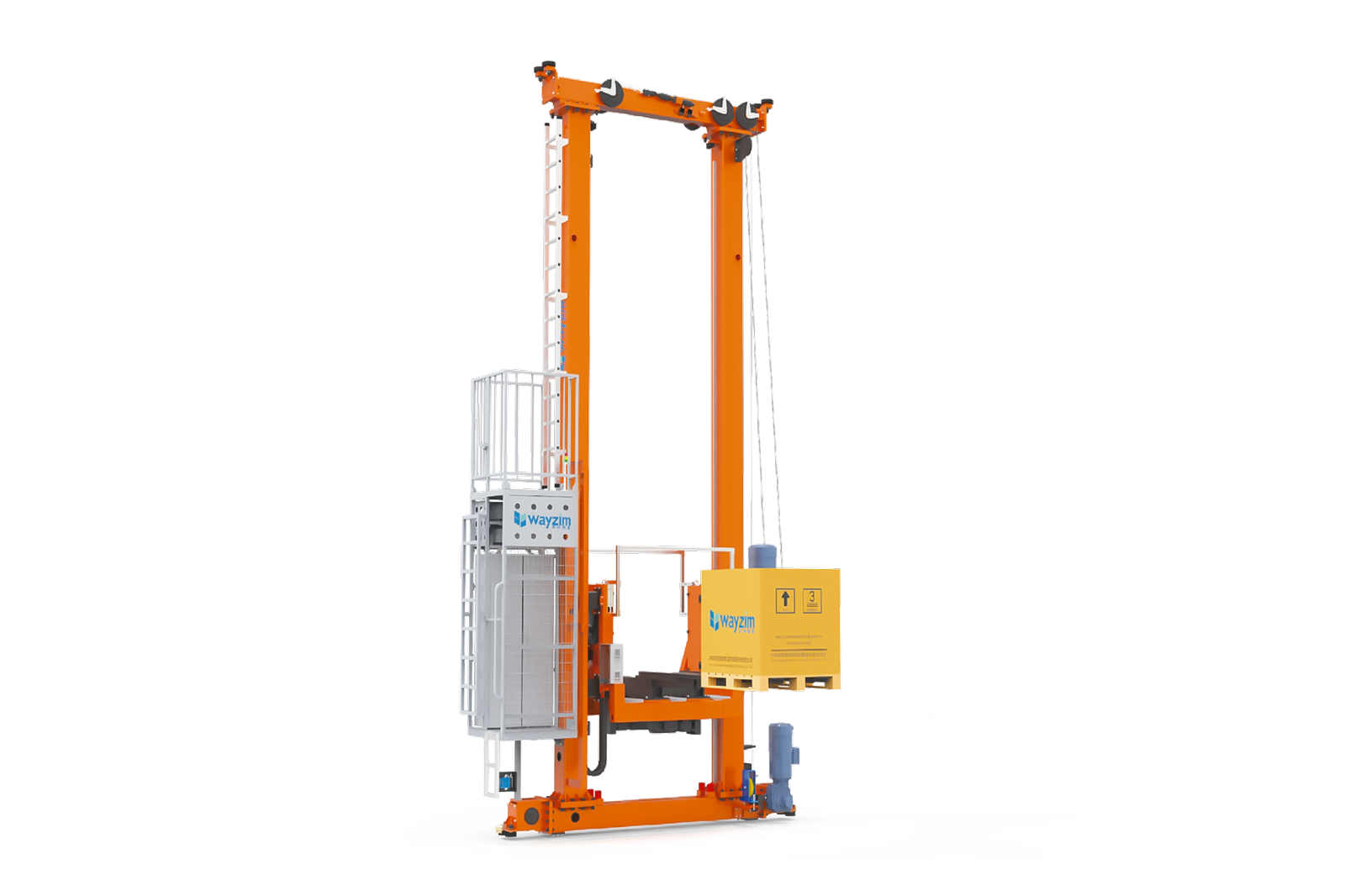

What is an AS/RS Pallet Stacker Crane? An Automated Storage and Retrieval System (AS/RS) Pallet Stacker Crane is a specialised machine designed for the efficient storage and retrieval of palletised goods in high-bay warehouses. It operates within a network of racking systems, traveling vertically and horizontally to access individual pallets stored at various heights and […]

In the fiercely competitive market of cross-border e-commerce, logistics timeliness is an important indicator affecting consumers’ shopping experiences. Timeliness plays an important role in building the brand image and reputation of e-commerce merchants. High timeliness can improve customer satisfaction and market competitiveness. This case depicts the application of Wayzim’s AMR solutions in a well-known cross-border […]

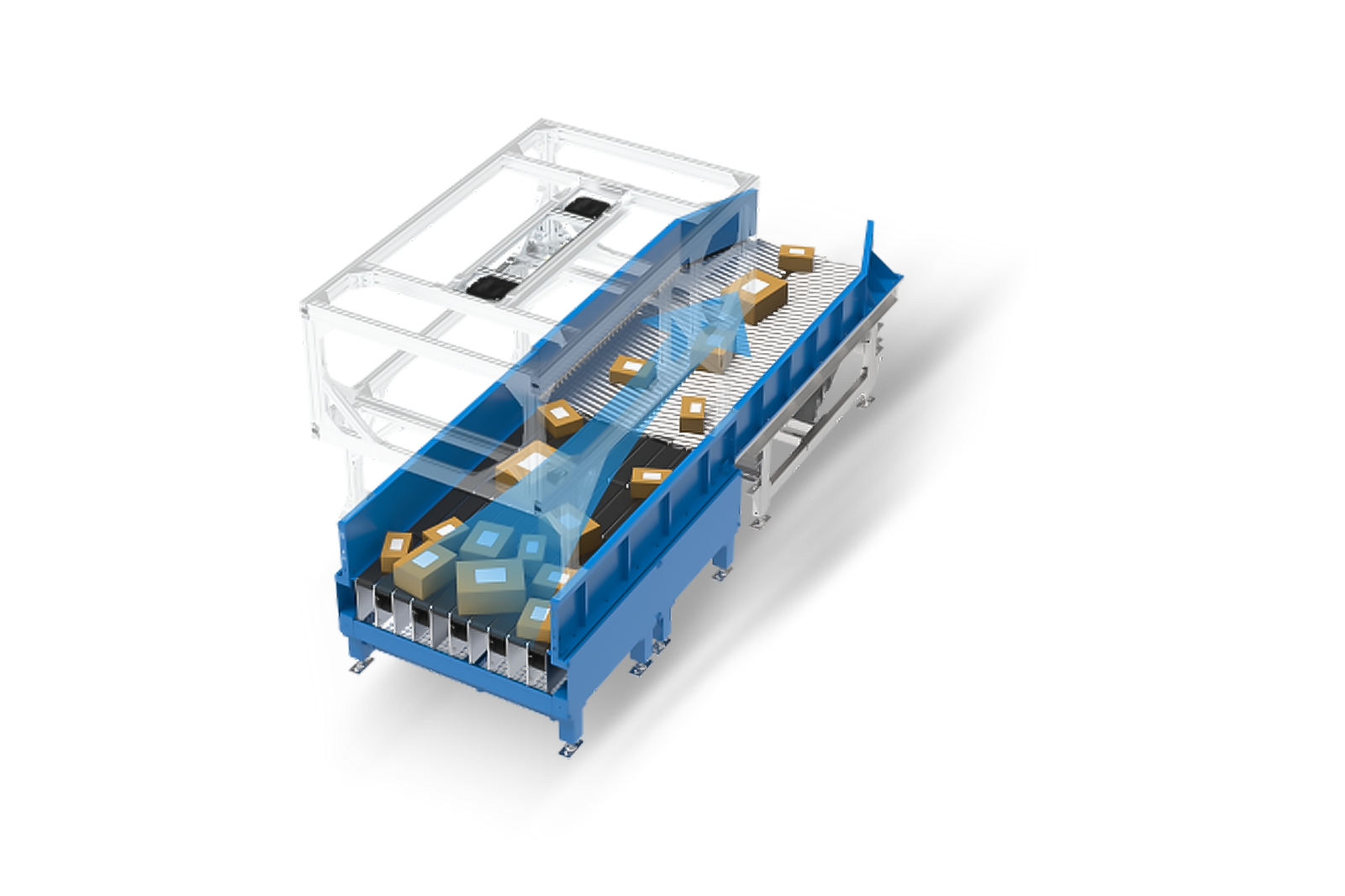

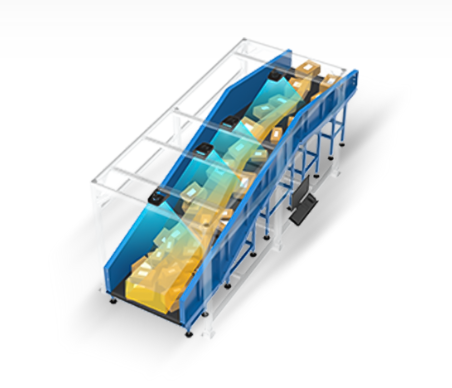

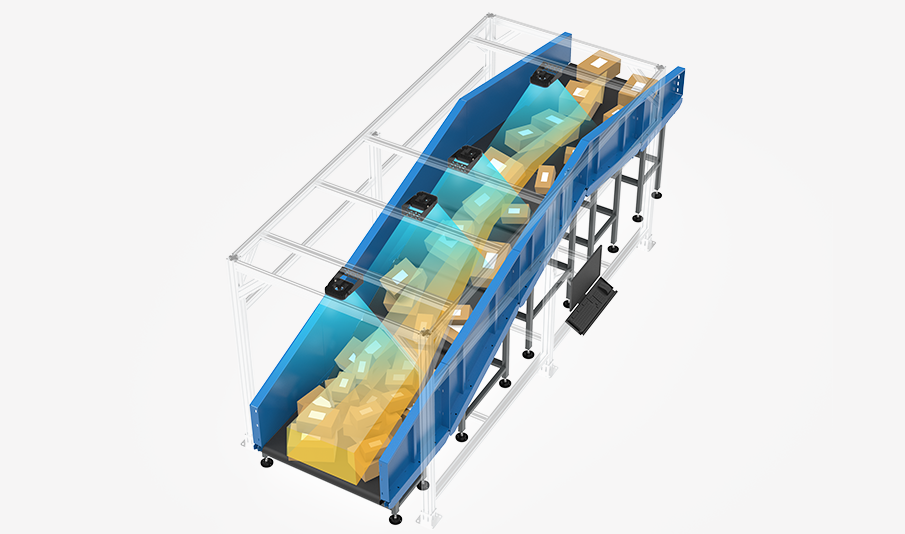

A 3D Bulk Flow Singulator (BFS) is a revolutionary automation technology designed to efficiently handle and separate unorganised piles of parcels, boxes, and other items in a warehouse environment. It tackles the challenge of “singulating,” meaning separating individual items from a bulk flow without damaging them or disrupting the overall workflow. How does it work? […]

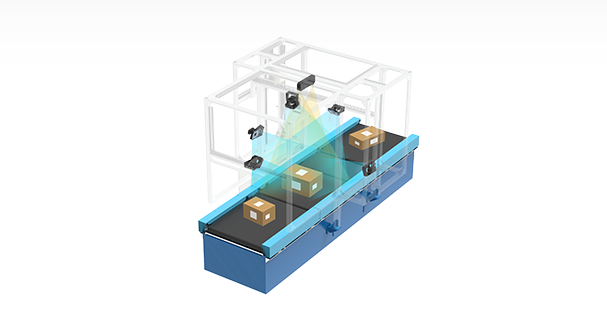

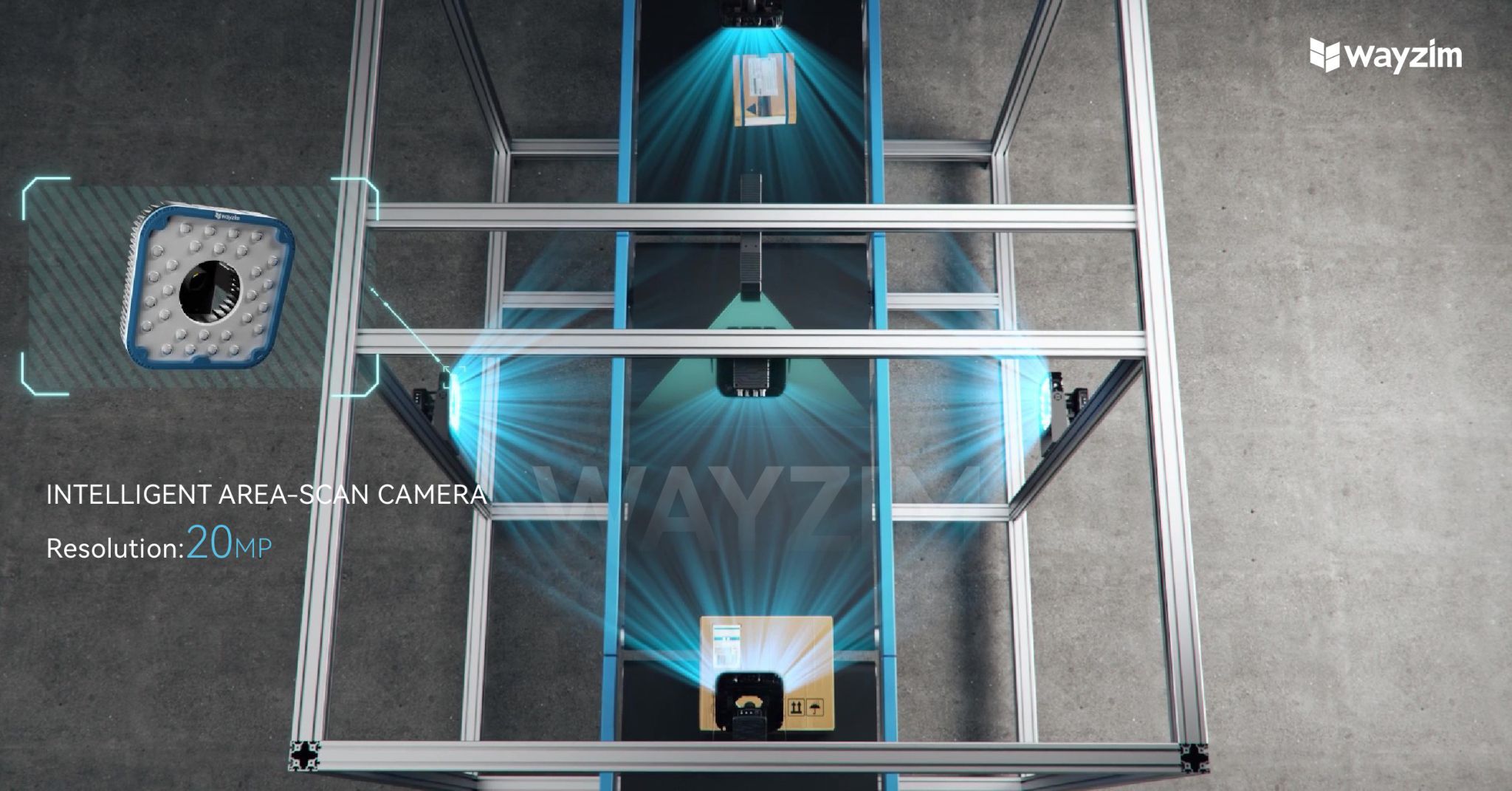

What is DWS? DWS stands for Dynamic Dimensioning, Weighing, and Scanning systems. It refers to a technology used in logistics and warehousing to automatically measure the dimensions, weight, and other characteristics of packages as they move along a conveyor belt. This data is crucial for various applications, including: Calculating shipping costs: Accurately measured dimensions and […]

In the fiercely competitive landscape of 3rd Party Logistics (3PL), staying ahead of the curve requires continuous innovation and optimisation. Automation has emerged as a transformative force, enabling 3PLs to revolutionise their operations and achieve a significant competitive edge. By streamlining processes, enhancing accuracy, and maximising efficiency, automation empowers 3PLs to deliver exceptional customer service […]

In the ever-evolving and competitive landscape of third-party logistics (3PL), embracing automation has become a strategic necessity for providers to thrive. Automation empowers 3PLs to achieve significant enhancements in efficiency, productivity, accuracy, and customer service, ultimately leading to sustained growth and profitability. Let me walk you through the multifaceted benefits of automation for 3PLs, highlighting […]

Warehouse Management System (WMS) is a software information system for fine management of warehouse goods, storage location, and quantity which is connected to ERP (Enterprise Resource Planning Management System), MES (Manufacturing Execution System), and WCS (Warehouse Control System). It is the extension and supplement of the warehouse management module in ERP and the source of […]

Along with the fast running of parcel conveyor belts, the 15th Double 11 Shopping Festival arrived. According to the data of the State Post Bureau of China, the express delivery volume during this year’s Double 11 reached a new high. On that single day, postal and express delivery companies across the country received a total […]

The industrial sector has witnessed remarkable advancements in recent years, and automated conveyor systems are one of the most significant innovations to date. These systems have revolutionised the way businesses operate, enhancing efficiency, productivity, and safety in various industries. In this article, we will delve into the world of automated conveyor systems, exploring their benefits, […]

Package handling facilities strive for efficiency. The faster they can move parcels through their system, the more packages they can process. One way they achieve this is with automated sorting systems like cross-belt sorters. This innovative technology offers a host of benefits for high-volume package handling operations. What is a Cross-Belt Sorter? A cross-belt sorter […]

When automating your warehouse or distribution centre, investing in automated sorting equipment is essential for efficiently moving and tracking inventory. One of the most versatile automated sorting systems is the cross-belt sorter. Cross-belt sorters provide high-speed sorting capabilities to maximise warehouse productivity. Understanding how cross-belt sorters work and their key benefits will help you determine […]

In the dynamic world of warehouse automation, the Tote Stacker Crane stands out as the pinnacle of innovation and efficiency. Designed specifically for small stereo warehouses, this cutting-edge equipment is an expert in optimising space and streamlining operations, making it an indispensable asset for industries ranging from electronics to fashion and from food to literature. […]

When managing inventory in a warehouse or fulfilment centre, efficiently sorting parcels is crucial for optimising operations. Implementing an intelligent express parcel sorting system allows you to accurately and quickly move inventory to ensure timely order fulfilment. With the rise of e-commerce and the demand for fast delivery, investing in automated parcel sorting is key […]

In the dynamic world of logistics, the express parcel sorting system by SmartlogitecX stands out as a groundbreaking solution tailored for diverse application scenarios. This integrated system employs intelligent sorting equipment that revolutionises the handling of parcels, ensuring their distribution is both standardised and intelligent. Innovative Cross-belt Sortation System The cross-belt sorter is a highlight […]

Package delivery services are essential to our modern economy. As online shopping continues to grow, the number of packages being shipped is increasing exponentially. This puts immense pressure on delivery companies to sort parcels quickly and efficiently. Automated parcel sorting systems provide a high-tech solution to this challenge. What are Automated Parcel Sorting Systems? Automated […]

Warehouse automation is the process of automating the movement of inventory within and across warehouses to customers with minimal human assistance. As part of an automation project, a business can eliminate labour-intensive duties that involve repetitive physical work and manual data entry and analysis. For instance, a warehouse worker may load an autonomous mobile robot […]

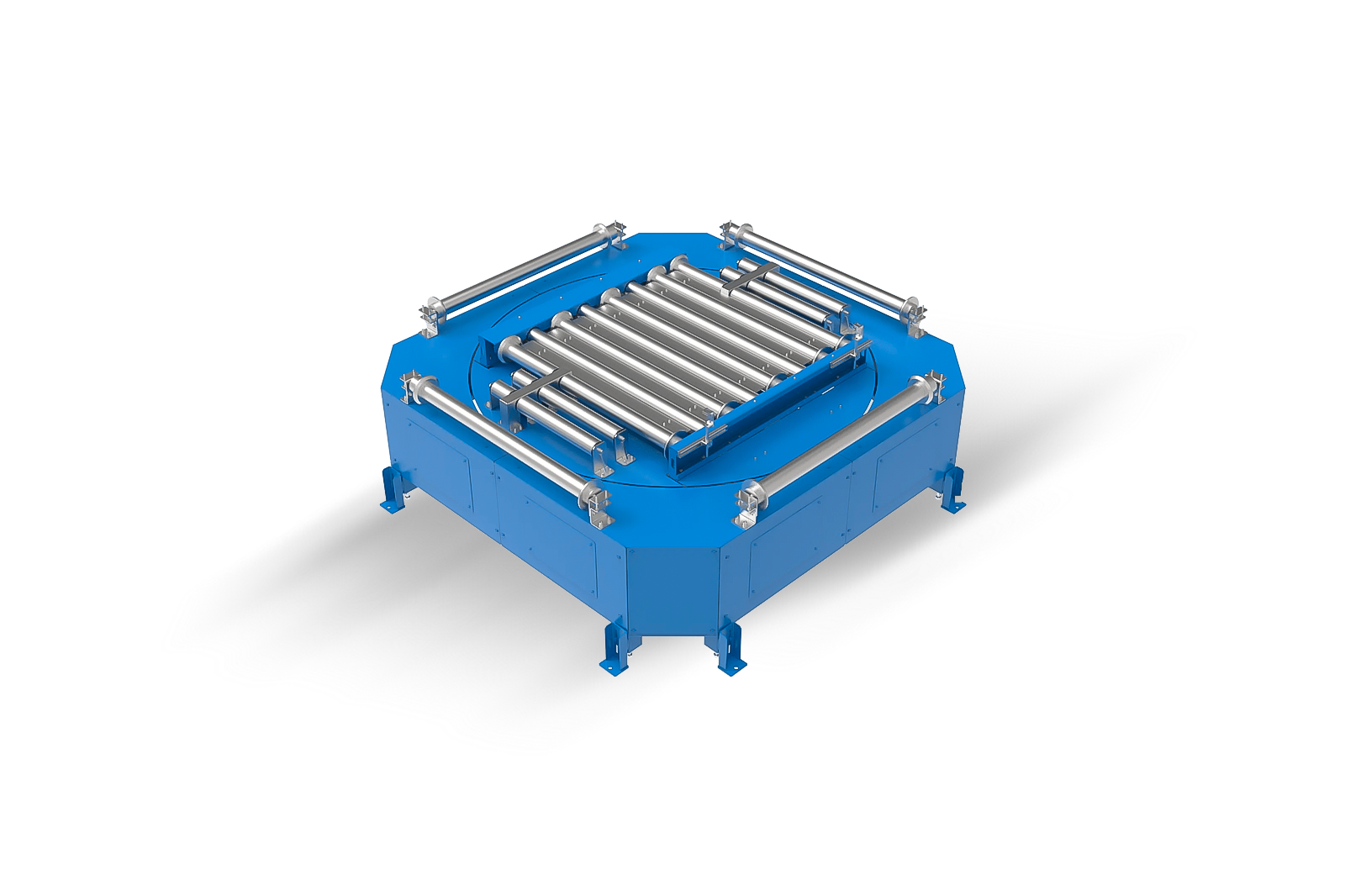

In the dynamic realm of warehouse automation, SmartlogitecX turntables, a significant automated conveyor system, play a crucial role in facilitating the smooth transfer and rotation of goods, enhancing productivity, and streamlining material flow. These versatile systems seamlessly integrate with various warehouse operations, enabling the precise movement of items between conveyor lines, accumulation zones, and workstations. […]

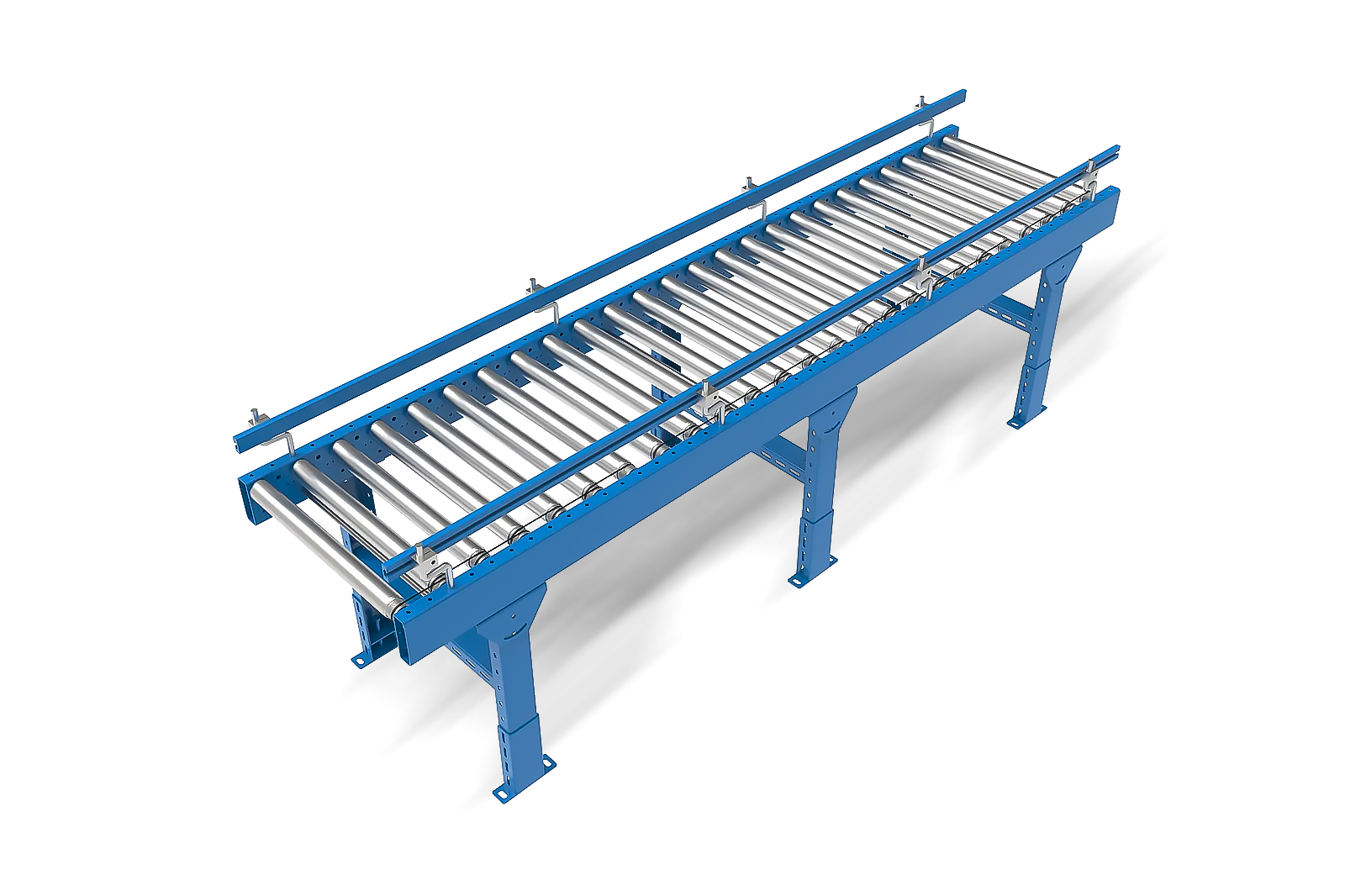

In the bustling realm of warehouse automation, SmartlogitecX pallet roller conveyors stand as a ubiquitous and essential component, facilitating the efficient movement and handling of palletised goods. These robust and versatile systems seamlessly integrate into warehouse layouts, providing a reliable and cost-effective solution for transporting pallets across various distances and elevations. Key Features and Advantages […]

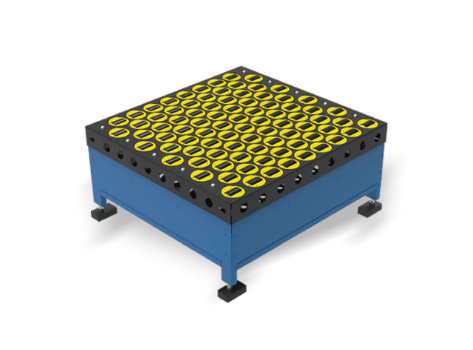

In the dynamic world of warehouse automation, the SmartlogitecX pivot wheel sorter stands out as a versatile and efficient solution for handling palletised goods. This innovative system seamlessly integrates with conveyor belts, enabling the precise movement and sorting of pallets in four directions: forward, backward, left, and right. Pivot wheel sorters are widely employed in […]

In the ever-evolving landscape of warehouse automation, SmartlogitecX 3D Bulk Flow Singulators have emerged as a revolutionary technology, transforming the way items are handled and singulated. These advanced systems seamlessly integrate with conveyor belts, employing sophisticated 3D vision technology and high-speed actuators to precisely separate and align items of varying sizes, shapes, and materials. By […]

In the dynamic world of warehouse automation, SmartlogitecX Dynamic Dimensioning, Weighing, and Scanning (DWS) systems have emerged as a crucial component of streamlining material handling operations and enhancing efficiency. These versatile systems seamlessly integrate with conveyor systems to capture precise dimensions, weights, and barcode information of items as they move along the conveyor belt. This […]

SmartlogitecX cross-belt sorter is a type of conveyor-based sortation system that utilises independently operated short conveyor belts mounted transversely along the main track. These cross belts, typically powered by electric motors, can rotate or move perpendicular to the main conveyor belt, enabling efficient sorting of items to various destinations. Cross belt sorters are widely employed […]

A SmartlogitecX Pallet four-way shuttle is an automated material handling system that is used to store and retrieve pallets within a warehouse or distribution centre. It is a type of Automated Storage and Retrieval System (ASRS) that utilises a shuttle to move pallets between storage racks and retrieval points. How Does a Pallet Four-Way Shuttle […]

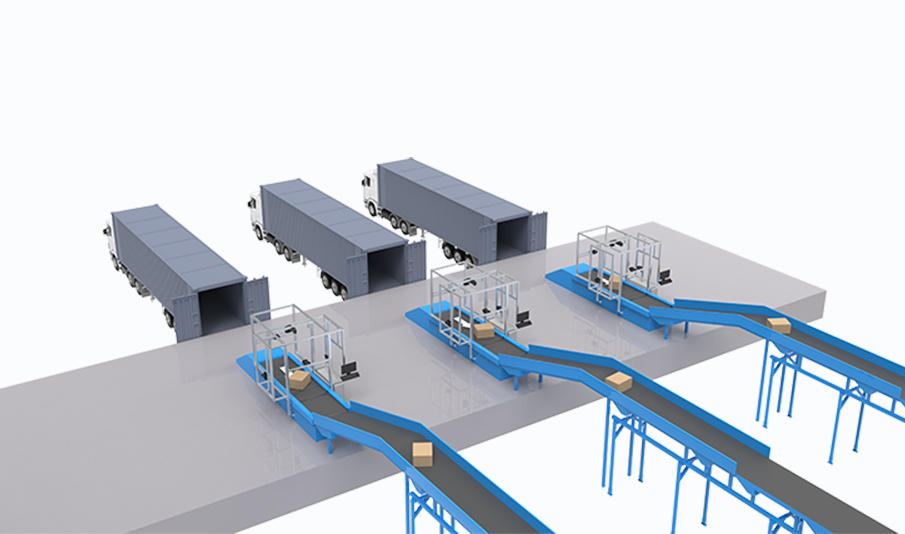

A SmartlogitecX linear sorter is an automated material handling system that efficiently sorts and distributes goods to designated destinations along a linear path. It is a versatile solution widely used in warehouses, distribution centres, and postal facilities to streamline sorting operations and enhance productivity. Key Features and Advantages of Linear Sorters Linear sorters offer several […]

In the dynamic world of warehouse automation, SmartlogitecX tote four-way shuttles have emerged as a versatile and efficient solution for handling smaller items. These automated systems seamlessly integrate with storage racks, enabling the precise movement and retrieval of totes, bins, and other containers in four directions: forward, backward, left, and right. Tote four-way shuttles are […]

A SmartlogitecX Tote Stacker Crane is an automated material handling system designed for storing and retrieving totes, bins, and other small containers within a high-bay warehouse or distribution centre. It is a versatile and efficient solution for optimising storage space and enhancing inventory management in facilities that handle a large volume of small items. Key […]

Out of many Automation Products, AGVs are known to be one of the essentials in warehouse automation. Automated Guided Vehicles (AGVs) are material handling systems that follow defined paths or guides to transport materials within a facility. They are commonly used in warehouses, manufacturing plants, and distribution centres to automate repetitive material movement tasks. AGVs […]

A SmartlogitecX Automated Storage and Retrieval System (ASRS) is a material handling system that utilises computer software and automation to store and retrieve materials from a designated storage area. ASRS systems are commonly used in warehouses and distribution centres to improve efficiency and productivity. They can be used to store a wide variety of materials, […]

The SmartlogitecX Dynamic DWS system is designed to provide high levels of customer satisfaction through its ability to perform automated operations like scanning, weighing, and measuring parcels quickly, accurately, and efficiently. Here are some ways in which the Dynamic DWS system compares to other sorting methods in terms of customer satisfaction: Speed The Dynamic DWS system […]

The purpose of warehouses extends beyond storage. They are also production lines, distribution centres and even logistics hubs. As each year passes, the number of functions they perform increases. SmartlogitecX Warehouse Automation brings a wide range of advantages, from running operations more efficiently to minimising human error. Here are some of the key reasons why […]