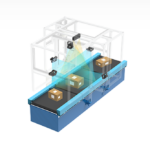

In the ever-evolving landscape of warehouse automation, 3D Bulk Flow Singulators have emerged as a revolutionary technology, transforming the way items are handled and singulated. These advanced systems seamlessly integrate with conveyor belts, employing sophisticated 3D vision technology and high-speed actuators to precisely separate and align items of varying sizes, shapes, and materials. By automating the singulation process, 3D bulk flow singulators significantly enhance productivity, efficiency, and accuracy in warehouse operations.

Key Features and Advantages of 3D Bulk Flow Singulators

3D Bulk Flow Singulators offer a range of compelling advantages that make them a valuable addition to warehouse automation.

- Unmatched Throughput

3D Bulk Flow Singulators can handle a high volume of items, making them suitable for applications with rapid sorting and singulation requirements. They can process thousands of items per hour, significantly outpacing traditional singulation methods. - Gentle Product Handling

Unlike traditional singulation methods that can damage delicate items, 3D Bulk Flow Singulators employ advanced singulation mechanisms that minimise product damage. Their precise control and gentle movements ensure the integrity of goods during the singulation process. - Unparalleled Versatility

3D Bulk Flow Singulators can accommodate a wide range of item sizes, shapes, and materials. They can handle items ranging from small packages and envelopes to large boxes and irregularly shaped objects, making them adaptable to various singulation applications. - Seamless Scalability

3D Bulk Flow Singulators can be easily integrated into existing conveyor systems and scaled to accommodate growing singulation needs and changing business requirements. Their modular design allows for flexible configuration and expansion. - Reduced Labor Costs

Automated singulation eliminates the need for manual labor, leading to lower labor costs and improved operational efficiency. By automating this repetitive task, businesses can reallocate their workforce to more value-added activities.

Components of a 3D Bulk Flow Singulator.

A 3D Bulk Flow Singulator typically consists of the following components:

- Conveyor Belt: The conveyor belt serves as the primary transport mechanism, moving items along the singulation path. It provides a smooth and controlled surface for item movement and positioning.

- 3D Vision System: A high-resolution 3D vision system captures detailed images of items on the conveyor belt. This system utilises advanced algorithms to analyse the size, shape, position, and orientation of each item.

- High-Speed Actuators: Strategically positioned along the conveyor belt, high-speed actuators, such as pneumatic or servo-controlled arms, precisely separate and align items. These actuators respond rapidly to the 3D vision data, ensuring accurate singulation.

- Advanced Control Systems: Complex control systems orchestrate the movement of items, process the 3D vision data, and activate the actuators to achieve accurate singulation. These systems optimise singulation strategies and ensure smooth operation.

- Intelligent Software: Sophisticated software manages the singulation process, including item identification, singulation logic, and system optimisation. This software continuously analyses data and adjusts parameters to maintain optimal performance.

Applications and Use Cases of 3D Bulk Flow Singulators.

3D Bulk Flow Singulators are widely used in various industries and applications:

In the fast-paced world of e-commerce fulfillment, 3D Bulk Flow Singulators play a crucial role in singulating and aligning items before picking and packing. They ensure efficient order fulfillment and meet the growing demand for rapid deliveries.

- Manufacturing facilities utilise 3D Bulk Flow Singulators to singulate and align components, parts, and finished goods within production lines and storage areas. This automation optimises production processes and enhances overall efficiency.

- Retail warehouses rely on 3D Bulk Flow Singulators to singulate and align products before picking and packing. This streamlines order fulfillment and inventory management, ensuring timely deliveries to customers.

- Postal and courier services employ 3D Bulk Flow Singulators to singulate and align mail, packages, and parcels before sorting and distribution. This automation improves processing efficiency and reduces manual labor requirements.

D3D Bulk Flow Singulators represent a cutting-edge solution for automating the singulation of bulk items in warehouses and distribution centres. Their ability to efficiently separate and align items of varying sizes and shapes makes them a valuable asset for businesses seeking to optimise their operations and enhance productivity. As technology advances, D3D Bulk Flow Singulators will become even more sophisticated and intelligent, further revolutionising the way items are handled and managed in warehouse environments.

Join forces with SmartlogitecX, backed by the technological strength of WayZim Technologies, and lead the charge in Warehouse Automation in Australia and New Zealand. We are more than a service; we are your strategic partner in redefining logistics. Opt for SmartlogitecX to harness the full potential of advanced technology, crafted with an understanding of the local market. Connect with our sales team to begin your journey towards an automated, efficient future.