The industrial sector has witnessed remarkable advancements in recent years, and automated conveyor systems are one of the most significant innovations to date. These systems have revolutionised the way businesses operate, enhancing efficiency, productivity, and safety in various industries. In this article, we will delve into the world of automated conveyor systems, exploring their benefits, types, and applications.

What are Automated Conveyor Systems?

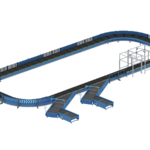

Automated conveyor systems are designed to transport materials, products, or goods from one place to another within a facility or warehouse. These systems consist of a series of interconnected conveyor belts, rollers, and other components that work in tandem to move items through various stages of production, processing, or distribution. Automated conveyor systems are equipped with advanced technologies, such as sensors, motors, and control systems, which enable efficient and precise material handling.

Benefits of Automated Conveyor Systems

The implementation of automated conveyor systems can bring numerous benefits to industries, including:

Enhanced Efficiency: Automated conveyor systems can significantly improve productivity by reducing the need for manual labor and streamlining material handling processes. By automating tasks such as loading, unloading, and transporting goods, businesses can allocate their workforce to more critical tasks, leading to increased efficiency.

Improved Safety: Automated conveyor systems minimise the risk of workplace accidents and injuries by reducing the need for employees to handle heavy or hazardous materials. These systems can also detect potential issues and alert operators to take necessary action, ensuring a safer working environment.

Increased Flexibility: Automated conveyor systems can be customised to accommodate various industries and applications, offering flexibility in terms of layout, design, and functionality. Businesses can tailor their conveyor systems to meet specific production requirements, making them an ideal solution for diverse industries.

Reduced Maintenance: Automated conveyor systems are designed to require minimal maintenance, reducing downtime and increasing overall system availability. These systems are built with durable components and equipped with advanced sensors that detect potential issues before they become major problems.

Cost Savings: By reducing labor costs, minimising maintenance, and increasing efficiency, automated conveyor systems can help businesses save substantial amounts of money. These cost savings can be reinvested in the company, enabling businesses to grow and expand their operations.

Types of Automated Conveyor Systems

Automated conveyor systems come in various types, each designed to cater to specific industry needs and applications.

Some of the most common types include:

Belt Conveyors: Belt conveyors are the most commonly used type of automated conveyor system. These systems feature a continuous belt that moves materials or products along a fixed path. Belt conveyors are widely used in industries such as manufacturing, food processing, and logistics.

Roller Conveyors: Roller conveyors use a series of rollers to move items along a fixed path. These systems are ideal for handling heavy or bulky items, such as boxes, crates, or machinery. Roller conveyors are commonly used in warehouses, distribution centres and manufacturing facilities.

Chain Conveyors: Chain conveyors use a chain-driven system to move materials or products along a fixed path. These systems are suitable for handling heavy or abrasive materials, such as metal parts or construction materials. Chain conveyors are often used in industries such as automotive, mining, and construction.

Overhead Conveyors: Overhead conveyors are designed to transport materials or products overhead, reducing the need for floor space. These systems are ideal for industries with limited space, such as automotive manufacturing, aerospace, and food processing.

Applications of Automated Conveyor Systems

Automated conveyor systems have numerous applications across various industries, including:

Manufacturing: Automated conveyor systems are widely used in manufacturing facilities to transport raw materials, work-in-progress, and finished goods. These systems streamline production processes, improving efficiency and productivity.

Logistics and Distribution: Conveyor systems are essential in logistics and distribution centers, where they are used to sort, store, and transport goods. Automated conveyor systems help speed up order fulfillment processes, ensuring timely delivery to customers.

Food Processing: The food processing industry relies heavily on automated conveyor systems to transport raw materials, work-in-progress, and finished products. These systems are designed to meet strict sanitation and safety standards, ensuring the quality and safety of food products.

Healthcare: Automated conveyor systems are used in healthcare facilities to transport medical supplies, equipment, and even patients. These systems help maintain a sterile environment, reduce noise levels, and improve patient care.

E-commerce: With the rise of e-commerce, automated conveyor systems are becoming increasingly popular in warehouses and distribution centres. These systems help streamline order fulfillment processes, reducing delivery times, and improving customer satisfaction.

Automotive: The automotive industry uses automated conveyor systems to transport parts, components, and vehicles throughout the production process. These systems help improve efficiency, productivity, and quality control.

Benefits of Automated Conveyor Systems

The benefits of automated conveyor systems are numerous and far-reaching. Some of the most significant advantages include:

Increased Efficiency: Automated conveyor systems can significantly improve efficiency by reducing the need for manual labor and streamlining material handling processes. By automating tasks such as loading, unloading, and transporting goods, businesses can allocate their workforce to more critical tasks, leading to increased productivity.

Improved Safety: Automated conveyor systems minimise the risk of workplace accidents and injuries by reducing the need for employees to handle heavy or hazardous materials. These systems can also detect potential issues and alert operators to take necessary action, ensuring a safer working environment.

Reduced Labor Costs: By reducing the need for manual labor, automated conveyor systems can help businesses save substantial amounts of money on labor costs. These cost savings can be reinvested in the company, enabling businesses to grow and expand their operations.

Improved Product Quality: Automated conveyor systems help maintain product quality by reducing the risk of damage or contamination. These systems can be designed to meet specific industry standards, ensuring the quality of products.

Increased Flexibility: Automated conveyor systems can be customised to accommodate various industries and applications, offering flexibility in terms of layout, design, and functionality. Businesses can tailor their conveyor systems to meet specific production requirements, making them an ideal solution for diverse industries.

Reduced Downtime: Automated conveyor systems are designed to require minimal maintenance, reducing downtime and increasing overall system availability. These systems are built with durable components and equipped with advanced sensors that detect potential issues before they become major problems.

Improved Customer Satisfaction: By streamlining production processes and reducing delivery times, automated conveyor systems can help businesses improve customer satisfaction. These systems enable businesses to meet customer demand more effectively, leading to increased customer loyalty and repeat business.

Automated conveyor systems are an essential component of modern-day material handling processes. These systems offer numerous benefits, including increased efficiency, improved safety, reduced labor costs, improved product quality, increased flexibility, reduced downtime, and improved customer satisfaction. By investing in automated conveyor systems, businesses can stay ahead of the competition, improve their bottom line, and maintain a strong reputation in their respective industries.