In a world of rapid e-commerce and on-demand shipping, a streamlined warehouse is a powerful business asset. At the heart of any efficient warehouse operation lies an optimised system of conveyors. If you’re looking to increase productivity, minimise manual handling, and boost overall efficiency, exploring the latest in warehouse conveyor systems is crucial.

RELATED: Streamline Your Operations with an Automatic Conveyor System

Understanding Your Warehouse Needs

Choosing the right warehouse conveyor system isn’t a one-size-fits-all solution. Factors such as the type of products you handle, the size and layout of your warehouse, and your specific fulfilment goals all play vital roles. Whether you require automated sortation for complex distribution or simple belt conveyors for efficient point-to-point transport, finding a custom-tailored solution is key.

Types of Warehouse Conveyor Systems

Let’s explore some common types of conveyor systems designed to tackle diverse warehouse challenges:

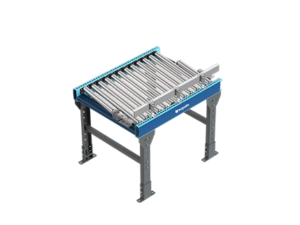

- Roller Conveyors: Highly versatile and ideal for transporting boxes, totes, and medium-weight packages.

- Belt Conveyors: Cost-effective and reliable, with various belt options to handle differing products and materials.

- Sortation Conveyors: Streamline package routing and order fulfilment with intelligent sorting systems, improving accuracy and speed.

- Automated Warehouse Conveyor Systems: Optimise throughput and cut labour costs with advanced, integrated conveyor solutions.

- Gravity Conveyors: A cost-effective option, they work well for short distances and manual unloading.

Boosting Efficiency with Smartlogitecx Conveyors

Here at Smartlogitecx, we recognise the critical role of warehouse conveyors in the modern supply chain. With our high-quality systems, designed for durability and precision, you can benefit from:

- Reduced labour dependency: Minimise manual handling, decrease costs, and redirect your workforce to focus on value-added tasks.

- Increased throughput: Faster and higher-volume product movement improves your ability to meet rising customer expectations.

- Improved order accuracy: Smart sortation solutions help eliminate picking and packing errors.

- Enhanced scalability: Modular conveyor systems offer the flexibility to adapt to changes in your business growth and changing demand.

RELATED: Warehouse Conveyor Systems: Powering Efficiency and Accuracy

FAQs

Q: How do I know which type of conveyor is best for my business?

A: Consulting expert technicians can analyse your operations and recommend the ideal system based on your materials, throughput needs, and space.

Q: What factors should I consider when choosing a warehouse conveyor system?

A: Important factors include load capacity, speed, conveyor length, type of goods handled, ease of maintenance, and integration capabilities with existing automation.

Q: What are the benefits of automated warehouse conveyor systems?

A: Automated systems increase throughput, reduce errors, lower labour costs, and offer flexibility for managing demand fluctuations.

Q: Can conveyors help improve safety in my warehouse?

A: Absolutely! Reducing manual handling, automating transport, and eliminating worker fatigue all contribute to enhanced warehouse safety.

SmartlogitecX, empowered by WayZim Technologies, is at the forefront of revolutionising Warehouse Automation in the Australian and New Zealand market. Be part of the logistics transformation. Embrace SmartlogitecX’s locally-focused, globally-backed expertise. Redefine your operations, harnessing the power of technology made for Australia and New Zealand. Ready to elevate your logistics? Reach out to the SmartlogitecX sales team for your customised automation solution.